Microwave sintering method of sea mud ceramsite

A technology of microwave sintering and sea mud, which is applied in the field of materials, can solve the problems of production raw materials and production equipment limitations, difficult to guarantee fly ash resources, high pollution, etc., to save sintering energy consumption, increase drying and sintering speed, and sinter high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

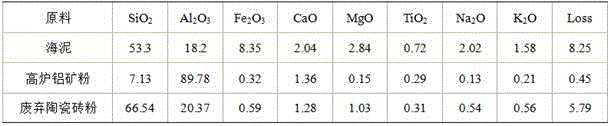

[0024] 1) Using sea mud with Fujian characteristics, after separation, drying and homogenization, its chemical composition is identified and analyzed. The mass fraction of each chemical composition in sea mud is SiO 2 53.3%, Al 2 o 3 18.2%, Fe 2 o 3 8.35%, CaO2.04%, MgO2.84%, TiO2 2 0.72%, Na 2 O 2.02%, K 2 O 1.58%, Cl - 1.06%, loss on ignition (IL) 8.25%;

[0025] 2) Humidity adjustment of sea mud, that is, first take part of the sea mud and dry it in the drying furnace, then determine the density of the completely dried sea mud, and then dry the sea mud used, when the density is 1.1 times the density of the completely dried sea mud After that, its water content is 10%;

[0026] 3) After homogenizing the sea mud, extrude it into raw meal balls with a particle size of 10~15mm with an extrusion ball machine;

[0027] 4) Put the raw material balls into a microwave oven with a frequency of 2.45GHZ, continuously heat up to 350°C at a heating rate of 12°C / min, and dry f...

Embodiment 2

[0030] 1) Using sea mud with Fujian characteristics, after separation, drying and homogenization, its chemical composition is identified and analyzed. The mass fraction of each chemical composition in sea mud is SiO 2 53.3%, Al 2 o 3 18.2%, Fe 2 o 3 8.35%, CaO2.04%, MgO2.84%, TiO2 2 0.72%, Na 2 O 2.02%, K 2 O 1.58%, Cl - 1.06%, loss on ignition (IL) 8.25%;

[0031] 2) Use the gravity separation method to remove the impurities in the selected sea mud;

[0032] 3) Use a ball mill to grind the waste ceramic bricks to obtain a powder with a particle size of 0.08~0.12mm;

[0033] 4) Mix 10% blast furnace aluminum ore powder, 20% waste ceramic brick powder and 70% sea mud, and stir in the mixing bin for 10 minutes to make it evenly stirred and control the water content at 10%;

[0034] 5) Extrude the mixed material obtained in 4) into raw meal balls with a particle size of 10-15 mm with a ball extrusion machine;

[0035] 6) Put the raw material balls into a microwave oven...

Embodiment 3

[0038] 1) Using sea mud with Fujian characteristics, after separation, drying and homogenization, its chemical composition is identified and analyzed. The mass fraction of each chemical composition in sea mud is SiO 2 53.3%, Al 2 o 3 18.2%, Fe 2 o 3 8.35%, CaO2.04%, MgO2.84%, TiO2 2 0.72%, Na 2 O 2.02%, K 2 O 1.58%, Cl - 1.06%, loss on ignition (IL) 8.25%;

[0039] 2) Use the gravity separation method to remove the impurities in the selected sea mud;

[0040] 3) Use a ball mill to grind the waste ceramic bricks to obtain a powder with a particle size of 0.08~0.12mm;

[0041] 4) Mix 15% blast furnace aluminum ore powder, 20% waste ceramic brick powder and 65% sea mud, and stir in the mixing bin for 15 minutes to make it evenly stirred and control the water content at 10%;

[0042] 5) Extrude the mixed material obtained in 4) into raw meal balls with a particle size of 10-15 mm with a ball extrusion machine;

[0043] 6) Put the raw material balls into a microwave ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com