Sintering furnace for preparing nanometer ceramics

A nano-ceramic and sintering furnace technology, applied in the field of sintering furnace, can solve the problems of poor heat preservation effect, uneven sintering, low sintering efficiency, etc., and achieve the effect of not being easily broken, large stretching range, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

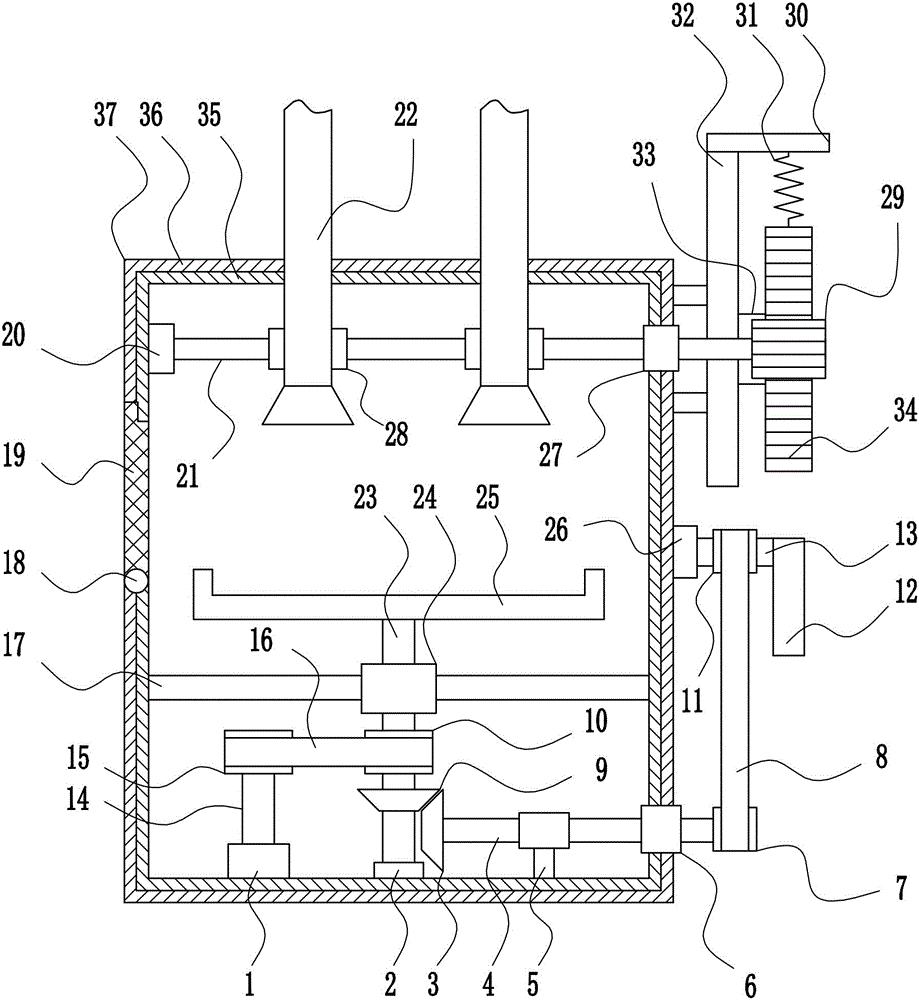

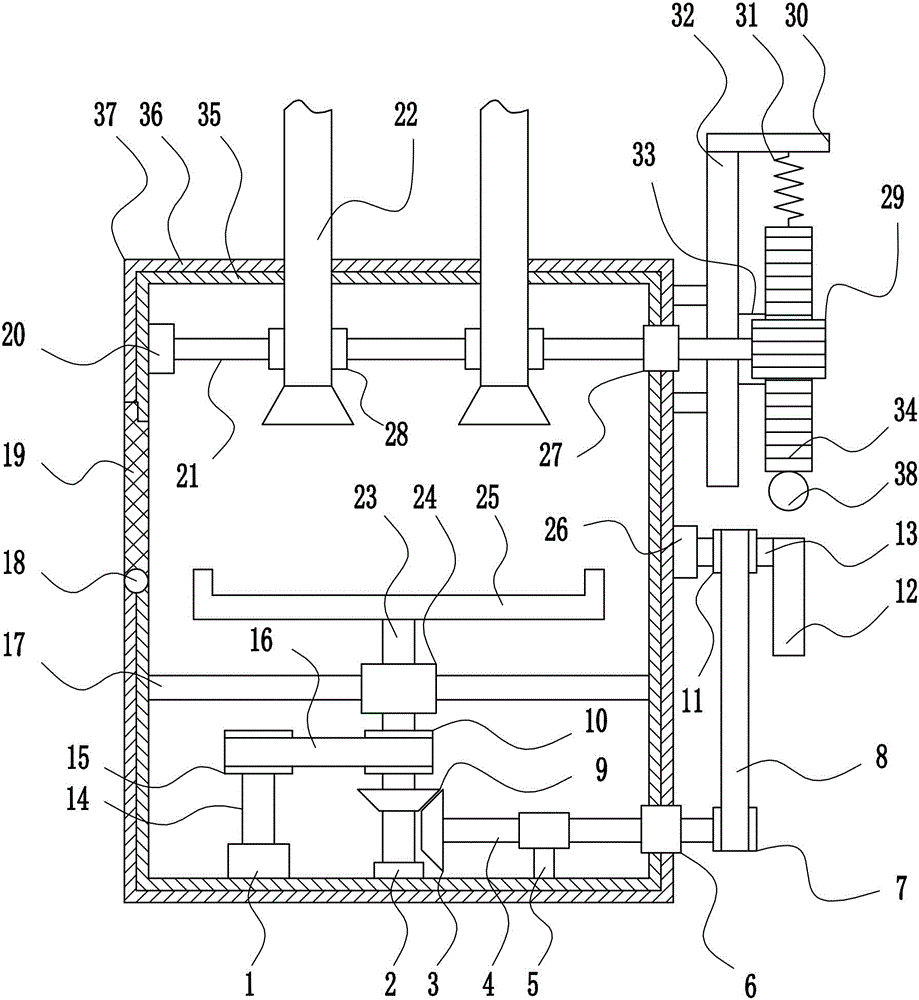

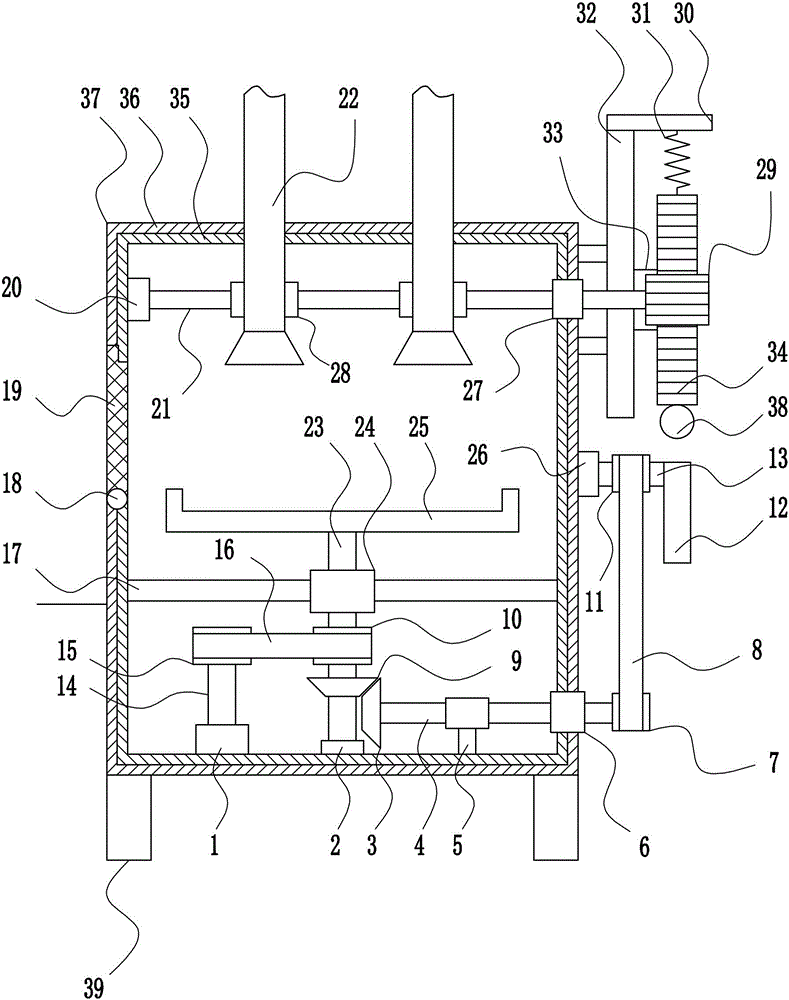

[0036] A sintering furnace for nano-ceramic preparation, such as Figure 1-5 As shown, it includes a rotating electrical machine 1, a first bearing seat 2, a first bevel gear 3, a first rotating shaft 4, a second bearing seat 5, a third bearing seat 6, a first pulley 7, a first flat belt 8, a first Two bevel gears 9, second pulley 10, third pulley 11, cam 12, second shaft 13, third shaft 14, fourth pulley 15, second flat belt 16, fixing plate 17, hinge member 18, cover plate 19 , the fourth bearing seat 20, the fourth shaft 21, the flame nozzle 22, the fifth shaft 23, the fifth bearing seat 24, the placing plate 25, the sixth bearing seat 26, the seventh bearing seat 27, the fixed sleeve 28, the circular Gear 29, baffle 30, elastic member 31, slide rail 32, slider 33, rack 34, refractory thermal insulation brick 35, aluminum silicate fiber felt 36 and shell 37, the shell 37 is provided with refractory thermal insulation brick 35, Aluminosilicate fiber felt 36 is filled betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com