Method and device for preparing photo anode in flexible solar cell through selective laser sintering

A flexible solar cell and selective technology, applied in the field of solar cells, can solve the problems of low production efficiency, long heating time, difficult mass production, etc., and achieve the effect of realizing efficient mass production and improving sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

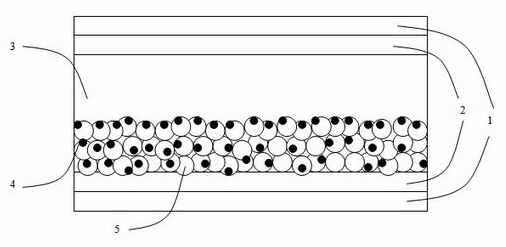

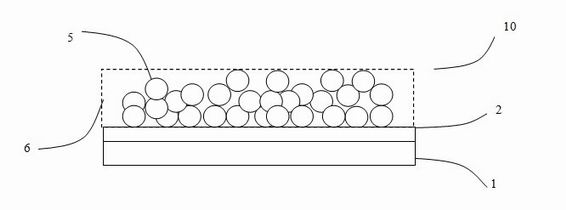

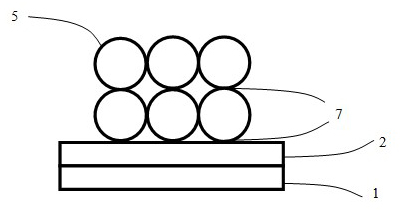

[0025] The present invention adopts the model 3W 3.4 micron mid-infrared OPO laser produced by Leishi Company, the output wavelength is 3.4 μm, and the continuous output power is from 0 to 10 watts. The focused spot size is 10mm×0.2mm, passing through a 0.2mm thick PEN flexible plastic substrate and a 100nm thick ITO conductive film to sinter the TiO2 nanoparticle porous film. The laser output mode is continuous output, TiO 2 The transmission speed of the photoanode is from 10mm / s to 900mm / s. Adjust laser power density from 5 W / cm 2 to 100 W / cm 2 When changing, TiO 2 Nanoparticle Porous Films of TiO 2 Between nanoparticles and TiO 2 The physical point contact between the nanoparticles and the conductive film is transformed into a neck-type chemical connection. When the laser energy density is high, TiO 2 The nanoparticles will be melted, but the PEN flexible plastic substrate will not be damaged.

[0026] In each example of the present invention, the scanning speed of ...

example 2

[0028] The present invention adopts the YLR-5-LP model fiber laser produced by IPG Company, the output wavelength is 1071nm, and the continuous output power is from 0 to 50 watts. Focusing spot size is 10mm×0.2mm, through 0.2mm thick PEN flexible plastic substrate and 100nm thick ITO conductive film, for TiO 2 Nanoparticle porous membranes were sintered. The laser output mode is continuous output, TiO 2 The transmission speed of the photoanode is from 100-700mm / s, and the power density of the output beam of the laser is adjusted from 3 watts / cm 2 to 60 W / cm 2 When changing, TiO 2 Nanoparticle Porous Films of TiO 2 Between nanoparticles and TiO 2 The physical point contact between the nanoparticles and the conductive film is transformed into a neck-shaped chemical connection. When the laser energy density is high, TiO 2 The nanoparticles will be melted, but the PEN flexible plastic substrate will not be damaged.

example 3

[0030] The present invention adopts the Awave-532-20W-25K model all-solid-state Q-switched green laser produced by American Lightwave Company, the output wavelength is 532nm, TiO 2 The transmission speed of the photoanode is 10-900mm / s, the frequency is set to 150kHz, the focus spot size is 10mm×0.2mm, it passes through the 0.2mm thick PEN flexible plastic substrate and the 100nm thick ITO conductive film, and the TiO 2 Nanoparticle porous membranes are sintered with quasi-continuous power densities from 8-100 W / cm 2 When changing, TiO 2 Nanoparticle Porous Films of TiO 2 Between nanoparticles and TiO 2 The physical point contact between the nanoparticles and the conductive film is transformed into a neck-type chemical connection until the TiO 2 The nanoparticles were melted, but the PEN flexible plastic substrate was not damaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com