Standard harmonic assembly speed-reducing mechanism of electric bicycle

A technology of electric bicycles and harmonics, which is applied to vehicle parts, vehicle gearboxes, transportation and packaging, etc., can solve problems such as low production efficiency, high manufacturing process requirements, and complex shapes, so as to improve production efficiency and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

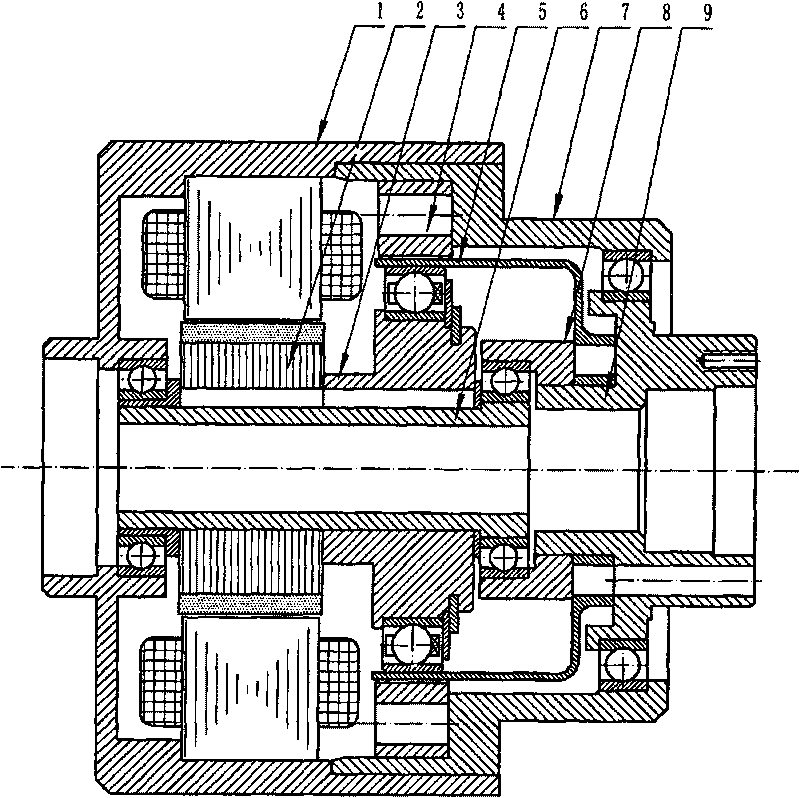

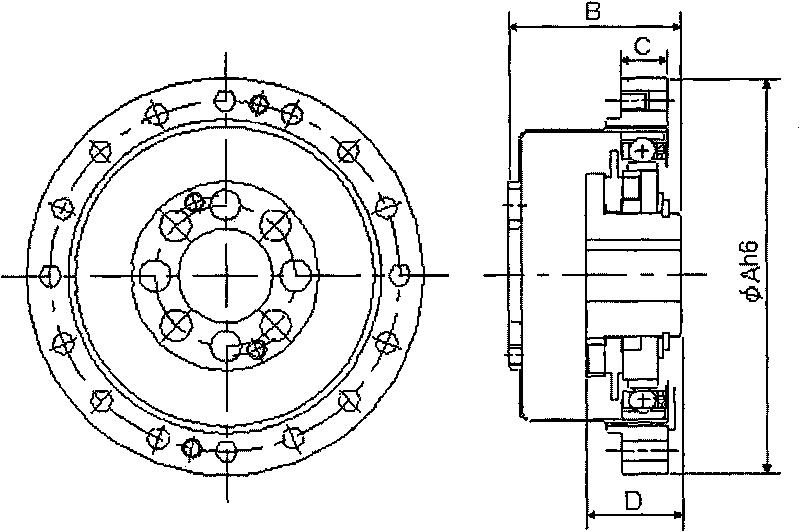

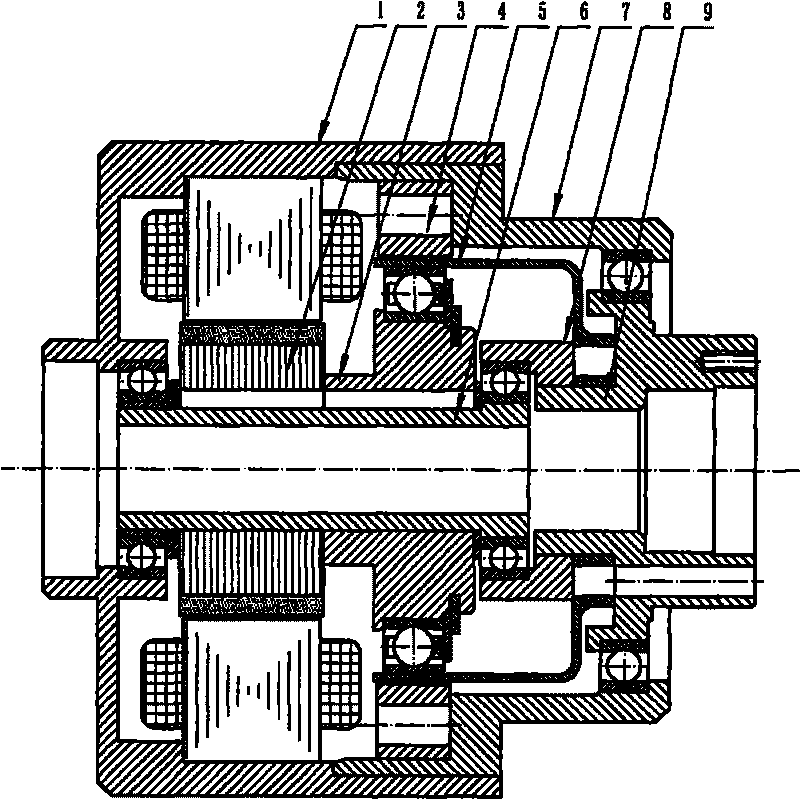

[0009] "1. Motor shell", "4. Harmonic rigid wheel", "7. Reducer shell" are press-fitted into one, and become a fixed part; "2. Motor rotor", "3. Harmonic generator" , "6. Center sleeve shaft" are press-fitted into one, and become a high-speed rotating part; Rotating parts and other three major parts.

[0010] The "8. Flexspline inner sleeve" configured on "5. Harmonic flexspline" is combined with the bearing and "6. Center sleeve shaft", and the "9. Flexspline outer cover" configured on "5. Harmonic flexspline" , combined with "7. Reducer housing" through bearings.

[0011] "1. Motor shell", "4. Harmonic rigid wheel", "7. Reducer shell" are fixed in the bicycle bottom bracket, "2. Motor rotor", "3. Harmonic generator", " 6. Center sleeve shaft" rotates at high speed in "1. Motor shell", "4. Harmonic rigid wheel", "7. Reducer shell", "5. Harmonic soft wheel" and "8. Soft wheel" Wheel inner sleeve", "9. Flex wheel outer jacket" in "2. Motor rotor", "3. Harmonic generator", "6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com