Nickel cobalt iron hydroxide coated nickel cobaltate flexible electrode material and preparation and application thereof

A hydroxide and flexible electrode technology, applied in the direction of fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., to save time and resources, high cycle stability, and considerable charge-discharge specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

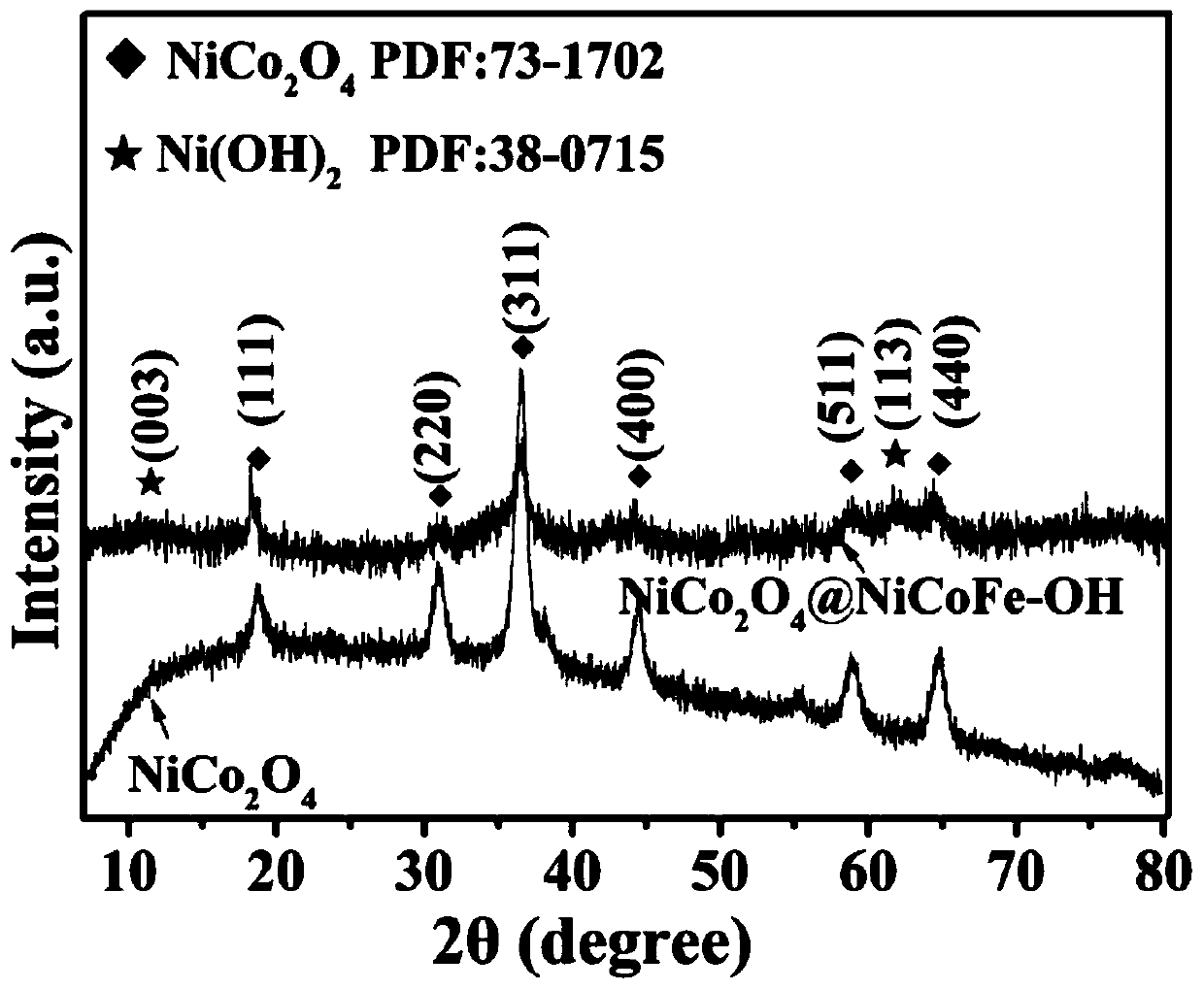

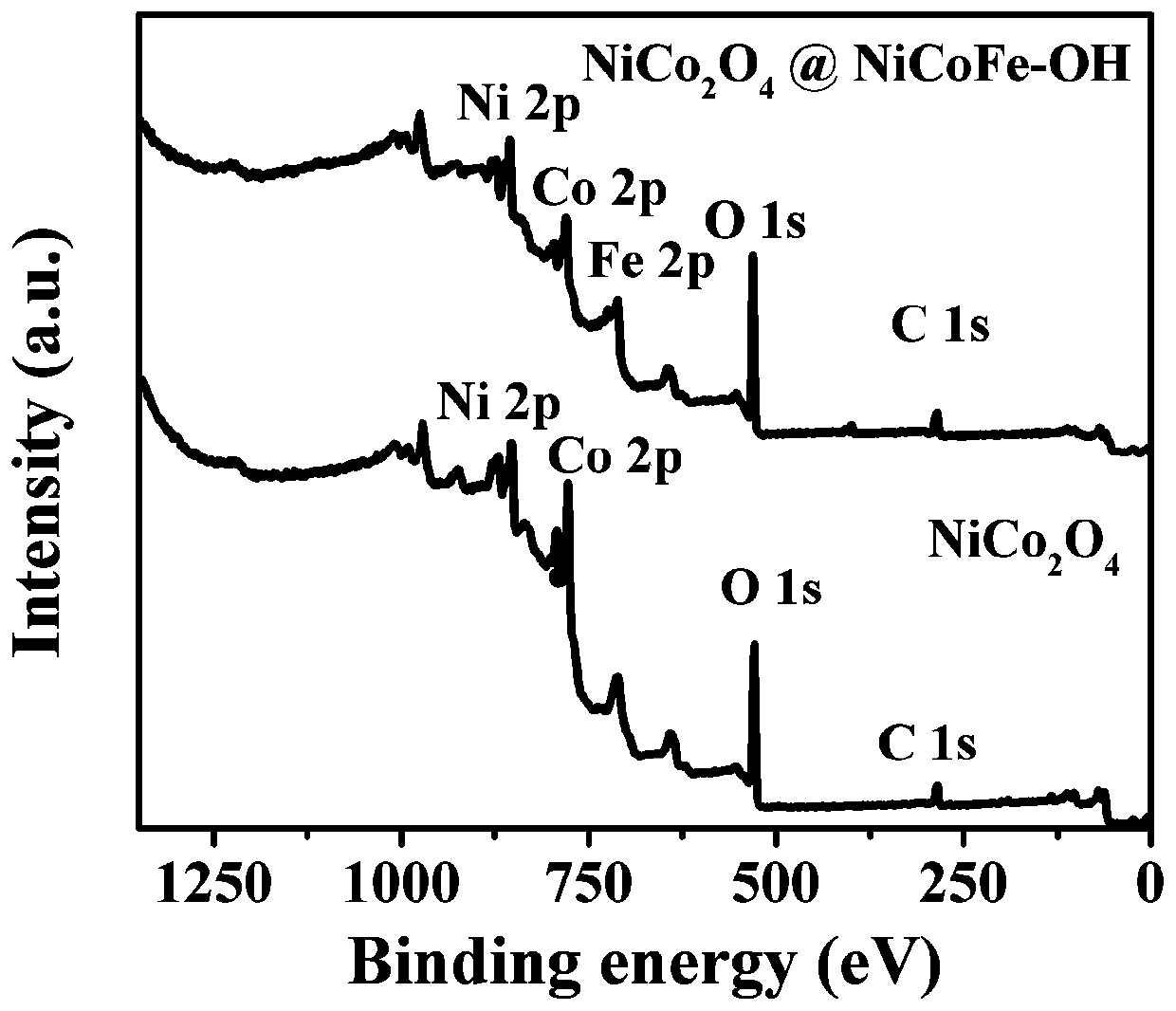

[0048] The preparation method of nickel cobalt oxide flexible electrode material coated with nickel cobalt iron hydroxide in this embodiment, the specific preparation steps are as follows:

[0049] (1) Preparation of nickel cobaltate electrode: ultrasonically dissolve 1.8g nickel nitrate, 3.6g cobalt nitrate, and 4.5g urea in a mixed solution of 110ml ethanol and 110ml deionized water to obtain a uniform pink solution; take 35ml pink mixed solution and pour Put it into a reaction kettle with a capacity of 50ml, carbon cloth (2*5cm 2 ) suspended in pink liquid, reacted with solvent heat at 100°C for 12 hours, cooled to room temperature after the reaction, took out the carbon cloth, and the pink substance was attached to the carbon cloth base, and was washed repeatedly with distilled water and ethanol until no free The precipitate was dried in an oven at 60°C; then, it was placed in a muffle furnace and calcined in an air atmosphere, rising from 0°C to a calcination temperature ...

Embodiment 2

[0056] The preparation method of nickel cobalt oxide flexible electrode material coated with nickel cobalt iron hydroxide in this embodiment, the specific preparation steps are as follows:

[0057] (1) Preparation of nickel cobaltate electrode: ultrasonically dissolve 1.8g nickel nitrate, 3.6g cobalt nitrate, and 4.5g urea in a mixed solution of 110ml ethanol and 110ml deionized water to obtain a uniform pink solution; take 35ml pink mixed solution and pour Put the carbon cloth into a reaction kettle with a capacity of 50ml, suspend the carbon cloth in the pink liquid, conduct a solvothermal reaction at 100°C for 12 hours, cool to room temperature after the reaction, take out the electrode, and attach the pink substance to the carbon cloth base Repeatedly rinse with ethanol until there is no free sediment on the surface of the sample, dry it in an oven at 60°C, and then put it into a muffle furnace for calcination in an air atmosphere, rise from 0°C to a calcination temperature...

Embodiment 3

[0062] The preparation method of nickel cobalt oxide flexible electrode material coated with nickel cobalt iron hydroxide in this embodiment, the specific preparation steps are as follows:

[0063] (1) Preparation of nickel cobaltate electrode: ultrasonically dissolve 1.8g nickel nitrate, 3.6g cobalt nitrate, and 4.5g urea in a mixed solution of 110ml ethanol and 110ml deionized water to obtain a uniform pink solution; take 35ml pink mixed solution and pour Put the carbon cloth into a reaction kettle with a capacity of 50ml, suspend the carbon cloth in the pink liquid, and conduct a solvothermal reaction at 100°C for 12 hours. After the reaction, cool to room temperature, take out the electrode, and the pink substance is attached to the surface, and repeat it with distilled water and ethanol. Rinse until there is no free precipitate on the surface of the sample, dry it in an oven at 60°C, and then put it into a muffle furnace for calcination in an air atmosphere. Rise from 0°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com