Method for preparing hydrogenated copolymer from conjugated diene hydrogenated latex

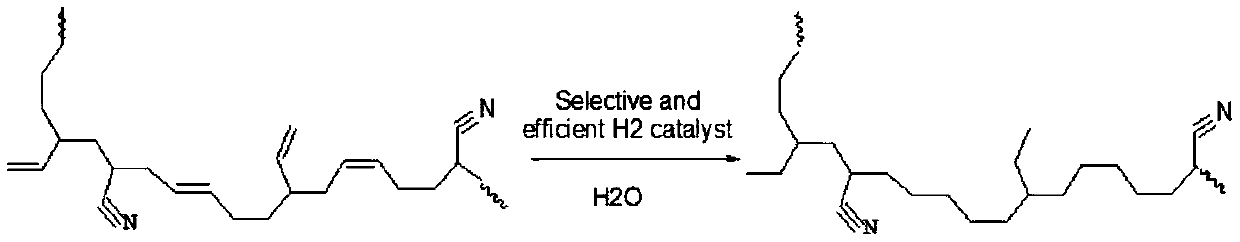

A technology of conjugated dienes and hydrogenated copolymers, which is applied in the field of hydrogenated copolymers prepared from conjugated dienes hydrogenated latex, can solve the problems of poor conversion rate, easy gel formation, environmental pollution, etc., and achieve the goal of reducing the total amount of additives. The effect of adding amount, improving catalytic efficiency and reducing industrial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

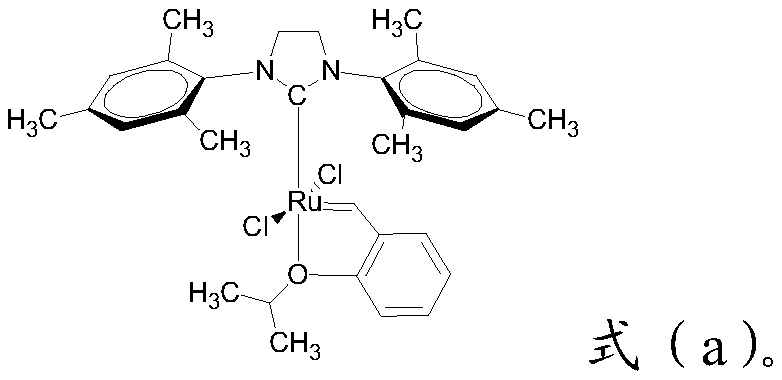

[0094] S1. Add 50 mL of latex and 0.000118 g of Hevida-Grubbs II into the reactor.

[0095] S2. Add 50 mL of latex, 2 g of potassium oleate, and 1 g of sodium tetradecenyl sulfonate, and stir at 200 rpm for 30 min.

[0096] S3. Nitrogen gas is introduced into the system, the degassing temperature is 25° C., the pressure is 2 MPa, the time is 60 minutes, and the stirring speed is 200 rpm during degassing; after the degassing is completed, continue stirring for 4 hours.

[0097] S4. Raise the temperature to 90° C., raise the nitrogen pressure to 800 psi (5.52 MPa), and react for 50 minutes. The hydrogenated NBR latex is coagulated with ethanol to obtain a HNBR copolymer.

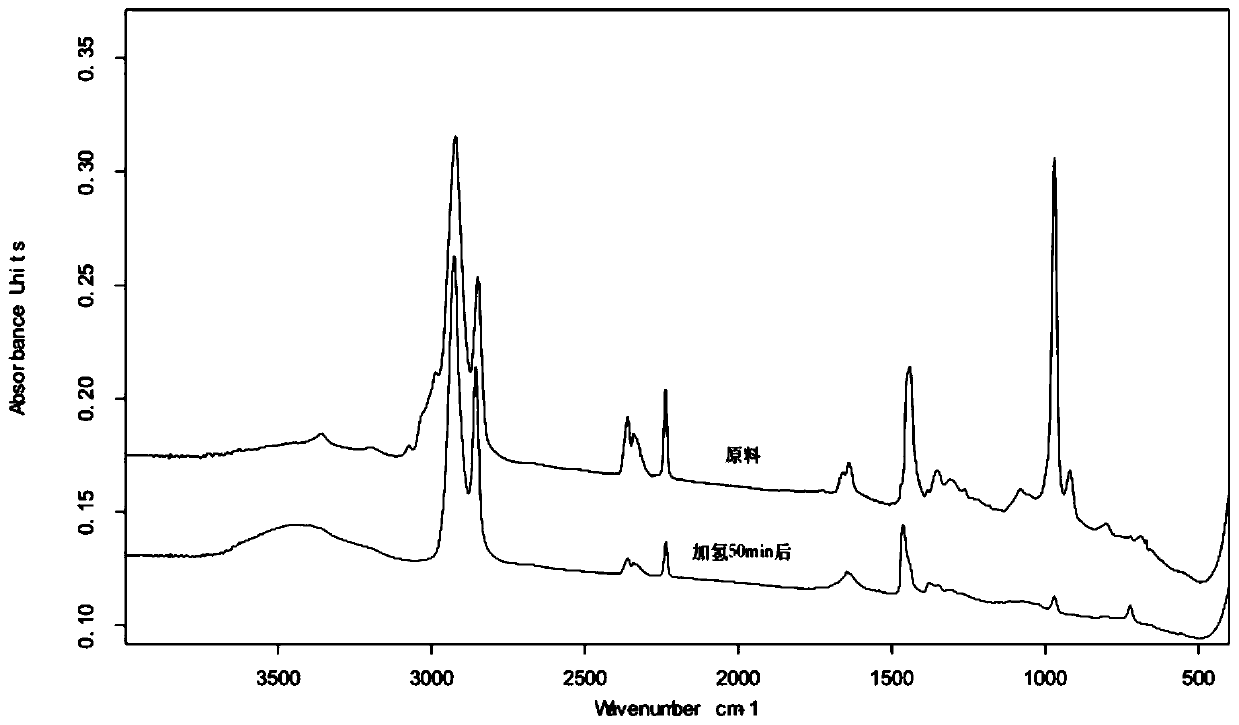

[0098] Infrared tests were carried out on the samples before and after hydrogenation, and the results were as follows: figure 1 as shown, figure 1 It is the infrared spectrogram of the sample before and after hydrogenation in Example 1 of the present invention. Wherein the upper line is the raw material, t...

Embodiment 2

[0102] S1. Add 50 mL of latex and 0.000122 g of Hevida-Grubbs II into the reactor.

[0103] S2. Add 50 mL of latex, 2 g of potassium oleate, and 0.5 g of sodium tetradecenyl sulfonate, and stir at 200 rpm for 30 min.

[0104] S3. Nitrogen gas is introduced into the system, the degassing temperature is 25° C., the pressure is 2 MPa, the time is 60 minutes, and the stirring speed is 200 rpm during degassing; after the degassing is completed, continue stirring for 4 hours.

[0105] S4. Raise the temperature to 90° C., raise the nitrogen pressure to 800 psi (5.52 MPa), and react for 85 minutes. The hydrogenated NBR latex is coagulated with ethanol to obtain a HNBR copolymer.

[0106] The results showed that no gel was produced in the reaction, and the obtained polymer was soluble in methyl ethyl ketone.

Embodiment 3

[0108] S1. Add 50 mL of latex and 0.000117 g of Hevida-Grubbs II into the reactor.

[0109] S2. Add 50 mL of latex, 2 g of potassium oleate, and 0.3 g of sodium tetradecenyl sulfonate, and stir at 200 rpm for 30 min.

[0110] S3. Nitrogen gas is introduced into the system, the degassing temperature is 25° C., the pressure is 2 MPa, the time is 60 minutes, and the stirring speed is 200 rpm during degassing; after the degassing is completed, continue stirring for 4 hours.

[0111] S4. The temperature is raised to 90° C., the hydrogen pressure is raised to 800 psi (5.52 MPa), and the reaction is carried out for 150 minutes. The hydrogenated NBR latex is coagulated with ethanol to obtain a HNBR copolymer.

[0112] The results showed that no gel was produced in the reaction, and the obtained polymer was soluble in methyl ethyl ketone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com