Special lubricating grease for ships and warships and preparation method of lubricating grease

A kind of lubricating grease, a special technology, applied in the field of lubricating grease, can solve problems such as insufficient adhesion, adverse effects on the normal operation of ship machinery, and poor seawater corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

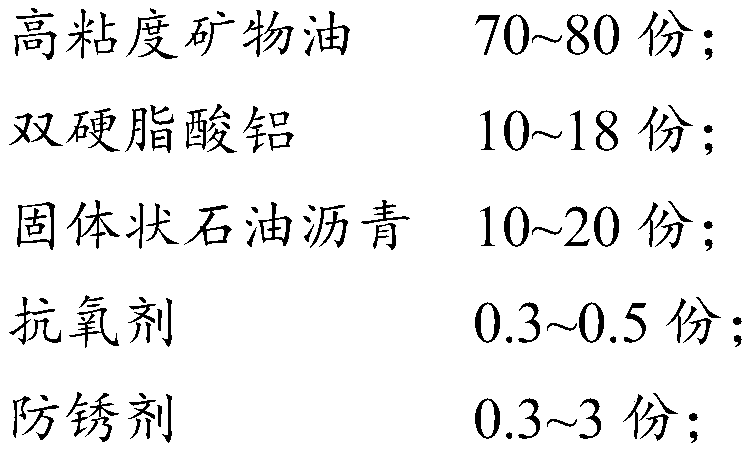

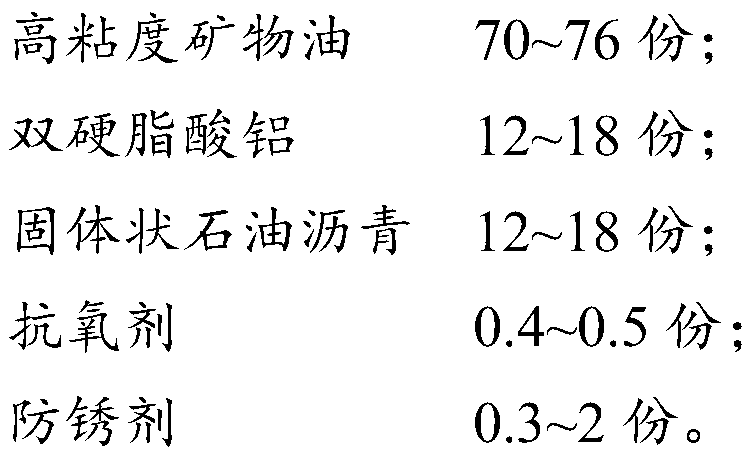

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides the preparation method of special lubricating grease for ships described in the above scheme, comprising the following steps:

[0039] (1) first mixing high-viscosity mineral oil and aluminum distearate at 150-160°C to obtain the first mixture;

[0040] (2) performing second mixing of the first mixture and solid petroleum pitch at 185-195°C to obtain a second mixture;

[0041] (3) performing a third mixing of the second mixture with the antioxidant and antirust agent at 90-100° C. to obtain the special grease for ships.

[0042] In the present invention, high-viscosity mineral oil and aluminum distearate are first mixed under the condition of 150-160 DEG C to obtain the first mixed material. In a specific embodiment of the present invention, the aluminum distearate is hydrolyzed after saponification reaction of stearic acid and aluminum isopropoxide according to the mass ratio of 8-14:3-6 in the process of preparing the first mixture Mad...

Embodiment 1

[0053] Add 190kg of high-viscosity mineral oil 150BS, (viscosity of 30cst at 100°C, pour point of -15°C) and 30kg of aluminum isopropoxide into the saponification kettle to fully dissolve, then slowly add 66kg of tertiary stearic acid at 90±5°C saponification at high temperature for 1 hour to obtain a saponification reaction solution;

[0054] Add 20kg of water to the saponification reaction solution and hydrolyze at 130°C for 25±5 minutes until the isopropanol is completely replaced, and keep it warm for 10 minutes to obtain a mixture of aluminum distearate and mineral oil;

[0055] Heat the mixture of aluminum distearate and mineral oil to 160±10°C, then add 190kg of mineral oil to thicken to obtain the first mixture;

[0056] Raise the temperature of the first mixture to 190°C, add 66kg of solid petroleum pitch (the softening point is 85°C, the penetration is 11), and stir for 10 minutes to obtain the second mixture;

[0057] Pass the second mixture through a 120-mesh filt...

Embodiment 2

[0059] Add 185kg of high-viscosity mineral oil 150BS (viscosity of 30cst at 100°C, pour point of -15°C) and 25.3kg of aluminum isopropoxide into the saponification kettle to fully dissolve, then slowly add 56kg of tertiary stearic acid at 95±5°C saponification at high temperature for 1 hour to obtain a saponification reaction solution;

[0060] Add 18kg of water to the saponification reaction solution and hydrolyze it at 130°C for 25±5 minutes until the isopropanol is completely replaced, and keep it warm for 10 minutes to obtain a mixture of aluminum distearate and mineral oil;

[0061] Heat the mixture of aluminum distearate and mineral oil to 160±10°C, then add 185kg of mineral oil to thicken to obtain the first mixture;

[0062] Raise the temperature of the first mixture to 190°C, add 61 kg of solid petroleum pitch (the softening point is 85°C, the penetration is 11), and stir for 10 minutes to obtain the second mixture;

[0063] Pass the second mixture through a 120-mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com