Electronic component, esp. one operating with acoustic surface waves (OFW component)

An electronic device and device technology, applied in the field of electronic devices, can solve the problems of non-sealing, damage, device function damage, etc., and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

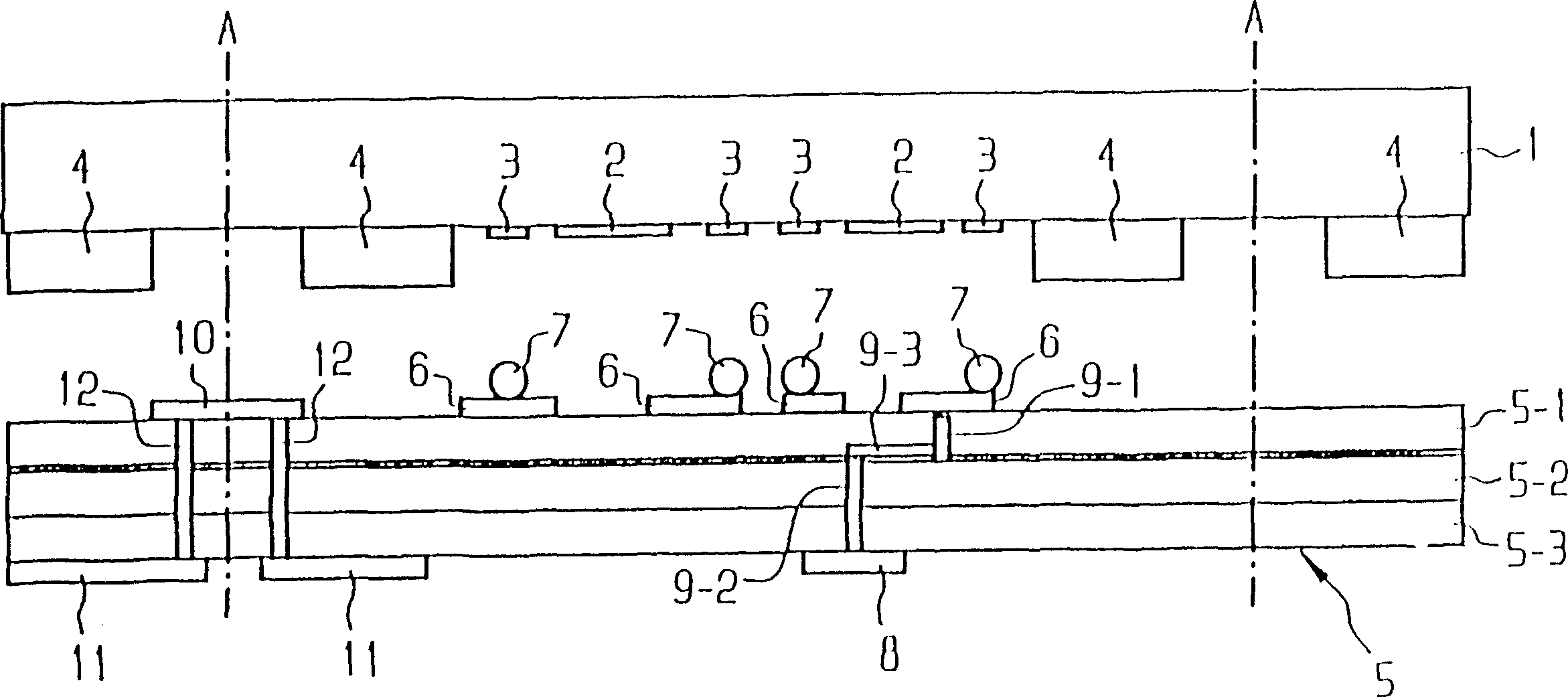

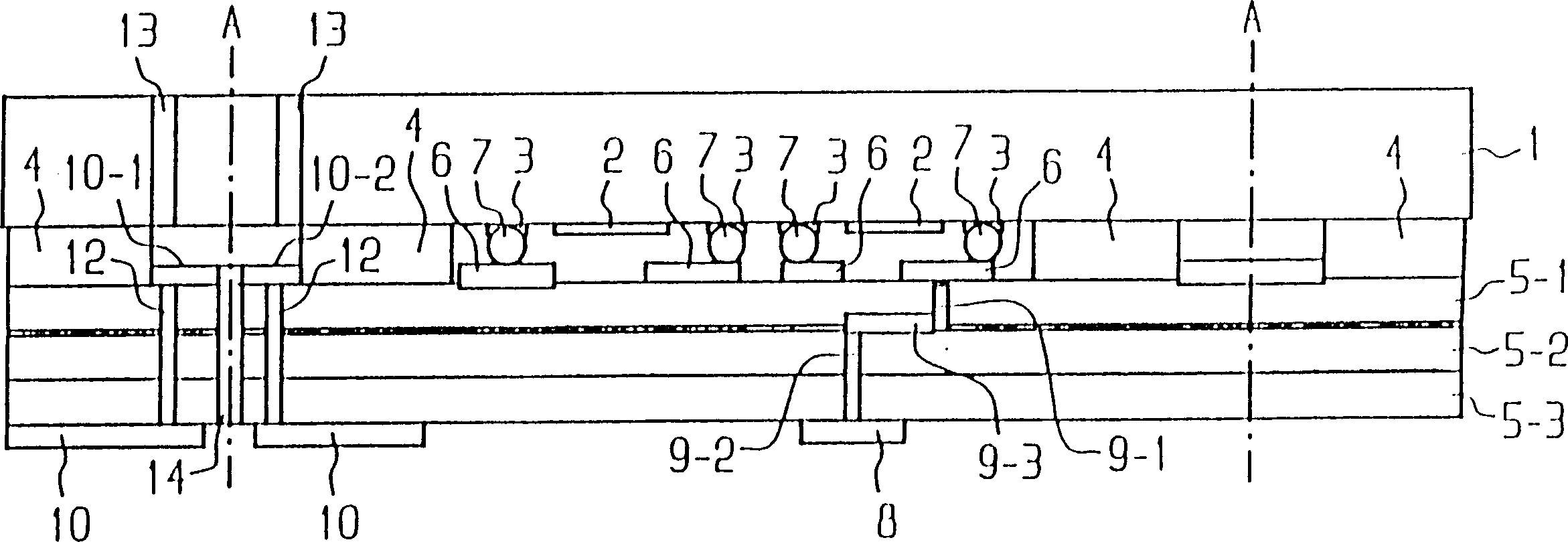

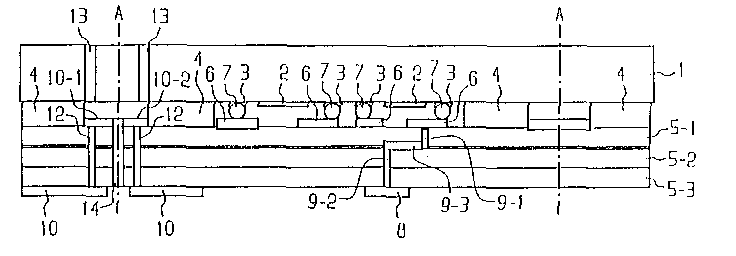

[0020] according to figure 1 The upper part of the OFW device system contains a piezoelectric substrate 1 and the above-mentioned conductive structure 2 , a connection plane 3 - pad - and a frame 4 surrounding the conductive structure 2 and the connection plane 3 . The conductive structure 2 can form, for example, an interdigital transducer, a resonator or a reflector.

[0021] For the sake of clarity, a larger number of device systems in the above-mentioned technologies can be located on one substrate at the same time, in figure 1 The central body 1 is exposed to the left and to the right by a vertical line A, in which a part of the frame 4 is also indicated.

[0022] In addition, there is a printed circuit board 5 on which side rails 6 perpendicular to the component system and contact elements 7 —pumps — are located thereon. In order to indicate a greater number of components, the printed circuit board is extended outwards by a line A.

[0023] device system and printed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com