Liquid anti-rust wax for long-term protection of ferrous metal and preparation method thereof

A ferrous metal and anti-rust wax technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as non-drying, poor adhesion of film anti-rust oil, general adhesion of anti-rust grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

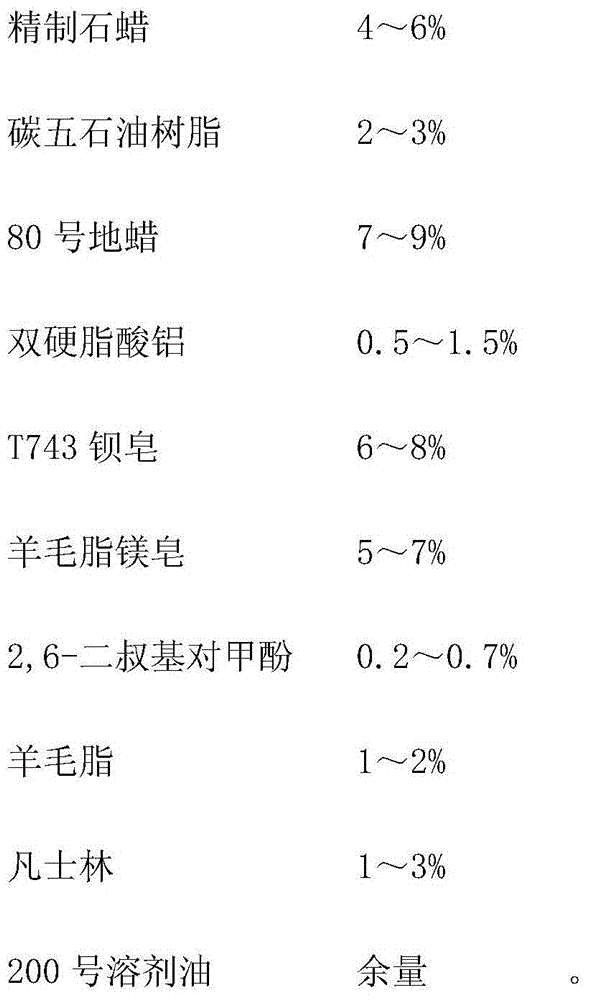

[0029] The preparation method of the above-mentioned liquid antirust wax for ferrous metal long-term protection comprises the following steps:

[0030] (1) Weigh refined paraffin wax, C5 petroleum resin, ozokerite wax No. 80, aluminum distearate, T743 barium soap, lanolin magnesium soap, 2,6-di-tert-cresol, lanolin, vaseline and 200 No. solvent oil, spare;

[0031] (2) Put one-third of No. 200 solvent oil, refined paraffin, C5 petroleum resin, No. 80 ozokerite and one-half of 2,6-di-tert-p-cresol into a reaction kettle, and heat it to 85~ 95 degrees Celsius, keep stirring at a speed of 100-120r / min during the heating process;

[0032] (3) Put one-third of No. 200 solvent oil, T743 barium soap, lanolin magnesium soap and one-half of 2,6-di-tert-p-cresol into another reaction kettle, heat to 90-110 degrees Celsius, Stir continuously at a speed of 100-120r / min during the heating process;

[0033] ⑷When the materials in the two reactors are completely dissolved, mix the two int...

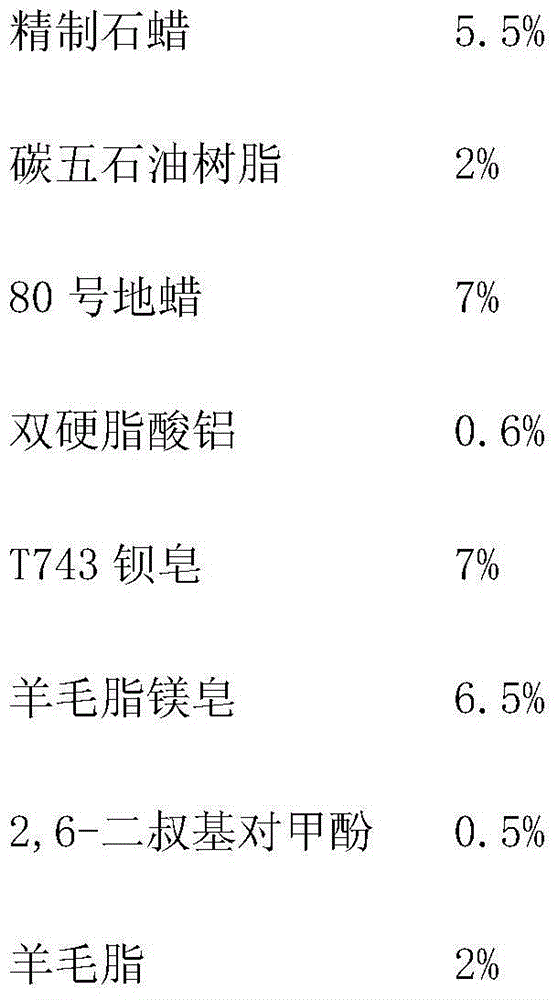

Embodiment 1

[0037]

[0038] The preparation method comprises the following steps:

[0039] (1) Weigh refined paraffin wax, C5 petroleum resin, ozokerite wax No. 80, aluminum distearate, T743 barium soap, lanolin magnesium soap, 2,6-di-tert-cresol, lanolin, vaseline and 200 No. solvent oil, spare;

[0040] (2) Put one-third of No. 200 solvent oil, refined paraffin, C5 petroleum resin, No. 80 ozokerite and one-half of 2,6-di-tert-p-cresol into a reaction kettle and heat it to 85 degrees Celsius , continuously stirring at a rotating speed of 100r / min during the heating process;

[0041] (3) Put one-third of No. 200 solvent oil, T743 barium soap, lanolin magnesium soap and one-half of 2,6-di-tert-p-cresol into another reaction kettle, heat to 90 degrees Celsius, and the heating process Continuously stir under the rotating speed of 100r / min in;

[0042] (4) When the substances in the two reactors are completely dissolved, mix the two into a new reactor, keep the temperature between 80 an...

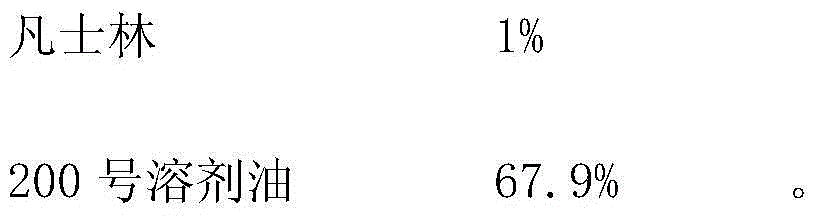

Embodiment 2

[0046]

[0047]

[0048] The preparation method comprises the following steps:

[0049] (1) Weigh refined paraffin wax, C5 petroleum resin, ozokerite wax No. 80, aluminum distearate, T743 barium soap, lanolin magnesium soap, 2,6-di-tert-cresol, lanolin, vaseline and 200 No. solvent oil, spare;

[0050] (2) Put one-third of No. 200 solvent oil, refined paraffin, C5 petroleum resin, No. 80 ozokerite and one-half of 2,6-di-tert-p-cresol into a reaction kettle and heat it to 95 degrees Celsius , continuously stirring at a rotating speed of 120r / min during the heating process;

[0051] (3) Put one-third of No. 200 solvent oil, T743 barium soap, lanolin magnesium soap and one-half of 2,6-di-tert-p-cresol into another reaction kettle, heat to 110 degrees Celsius, and the heating process Continuously stir under the rotating speed of 120r / min in;

[0052] (4) When the substances in the two reactors are completely dissolved, mix the two into a new reactor, keep the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com