Defoaming agent for water-based drilling fluid and preparation method thereof

A technology of water-based drilling fluid and defoamer, which can be applied in chemical instruments and methods, drilling compositions, etc., and can solve problems such as large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

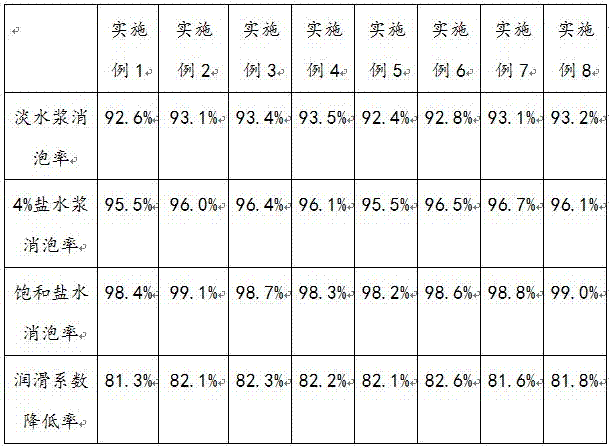

Examples

Embodiment 1

[0024] In this example, we use the following preparation methods:

[0025] Add 1500kg of diesel oil to the reactor with stirring device and temperature control device, start stirring, add 140kg of aluminum distearate when the temperature rises to 60°C, thicken in 10-20min, add 380kg of oleic acid immediately, and add 130kg of phosphoric acid after reacting for 10min Tributyl ester, 130kg of isooctyl alcohol was added after 30min, and the reaction was continued for 1h to discharge. During this period, the temperature is maintained at 60°C-65°C.

Embodiment 2

[0027] In this example, we use the following preparation methods:

[0028] Add 1500kg of aviation kerosene to the kettle with stirring device and temperature control device, start stirring, add 180kg of aluminum stearate when the temperature rises to 60°C, thicken in 10-20min, add 380kg of oleic acid immediately, and add 110kg of phosphoric acid after reacting for 10min Tributyl ester, 110kg of isooctyl alcohol was added after 30min, and the reaction was continued for 1h to discharge. During this period, the temperature is maintained at 65°C-70°C.

Embodiment 3

[0030] In this example, we use the following preparation methods:

[0031] Add 1500kg of aviation kerosene to the reaction kettle with stirring device and temperature control device, start stirring, raise the temperature to 60°C, add 160kg of aluminum distearate, thicken in 10-20min, add 380kg of isobutyl oleate immediately, and react for 10min Finally, 120kg of tributyl phosphate was added, 120kg of isooctyl alcohol was added after 30 minutes, and the reaction was continued for 1 hour to discharge. During this period, the temperature is maintained at 70°C-75°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com