Thixotropic electrostatic spraying anti-rust oil composition as well as preparation method and application thereof

An electrostatic spraying, anti-rust oil technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor thixotropic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

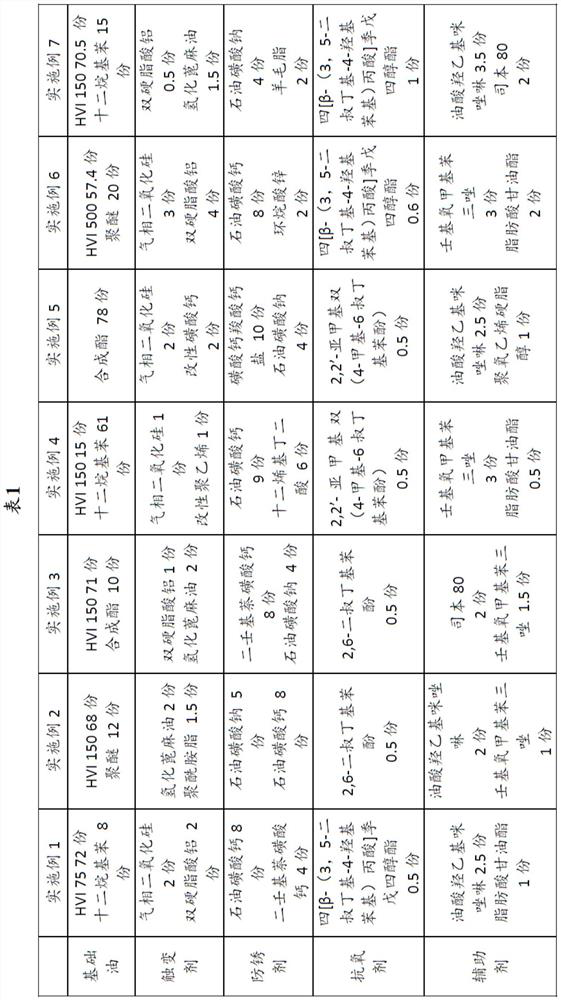

[0028] Embodiment 1 discloses a kind of thixotropic electrostatic spray antirust oil composition, comprising the following components in parts by weight:

[0029] Base oil: 72 parts of HVI 75, 8 parts of dodecylbenzene;

[0030] Thixotropic agent: 2 parts of fumed silica, 2 parts of aluminum distearate;

[0031] Barium-free rust inhibitor: 8 parts of calcium petroleum sulfonate, 4 parts of calcium dinonyl naphthalene sulfonate;

[0032] Antioxidant: tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.5 parts;

[0033] Auxiliary agent: 2.5 parts of oleic acid hydroxyethylimidazoline, 1 part of fatty acid glyceride;

[0034] The specific components and parts by mass of the antirust oil composition for thixotropic electrostatic spraying are recorded in Table 1.

[0035] The preparation method of the thixotropic electrostatic spraying antirust oil composition of the present embodiment is specifically as follows:

[0036] Heat the base oil to ...

Embodiment 2

[0038] Embodiment 2 discloses a kind of thixotropic electrostatic spray antirust oil composition, comprises the following components in parts by weight:

[0039] Base oil: 68 parts of HVI 150, 12 parts of polyether;

[0040] Thixotropic agent: 2 parts of hydrogenated castor oil, 2 parts of polyamide fat;

[0041] Barium-free rust inhibitor: 5 parts of sodium petroleum sulfonate, 8 parts of calcium petroleum sulfonate;

[0042] Antioxidant: 0.5 parts of 2,6-di-tert-butylphenol;

[0043] Auxiliary agent: 2 parts of oleic acid hydroxyethylimidazoline, 1 part of nonyloxymethylbenzotriazole derivative;

[0044] The specific components and parts by mass of the antirust oil composition for thixotropic electrostatic spraying are recorded in Table 1.

[0045] The preparation method of the thixotropic electrostatic spraying antirust oil composition of the present embodiment is specifically as follows:

[0046] Heat the base oil to 75°C and stir, then add thixotropic agent, barium-fr...

Embodiment 3

[0048] Embodiment 3 discloses a kind of thixotropic electrostatic spray antirust oil composition, comprises the following components in parts by weight:

[0049] Base oil: HVI 150 71 parts, synthetic ester 10 parts;

[0050] Thixotropic agent: 1 part of aluminum distearate, 2 parts of hydrogenated castor oil;

[0051] Barium-free rust inhibitor: 8 parts of dinonylnaphthalene sulfonate calcium salt complex, 4 parts of sodium petroleum sulfonate;

[0052] Antioxidant: 0.5 parts of 2,6-di-tert-butylphenol;

[0053] Auxiliary agent: 2 parts of Siben 80, 1.5 parts of nonyloxymethylbenzotriazole;

[0054] The specific components and parts by mass of the antirust oil composition for thixotropic electrostatic spraying are recorded in Table 1.

[0055] The preparation method of the thixotropic electrostatic spraying antirust oil composition of the present embodiment is specifically as follows:

[0056] Heat the base oil to 70°C and stir, then add thixotropic agent, barium-free rust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com