High-elasticity high-toughness polypropylene cable material for communication and preparation method thereof

A high-toughness, polypropylene technology, used in insulated cables, cables, circuits, etc., can solve the problems that elasticity and toughness cannot meet the needs of the market, improve toughness and elasticity, improve heat resistance, improve tensile strength and The effect of elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

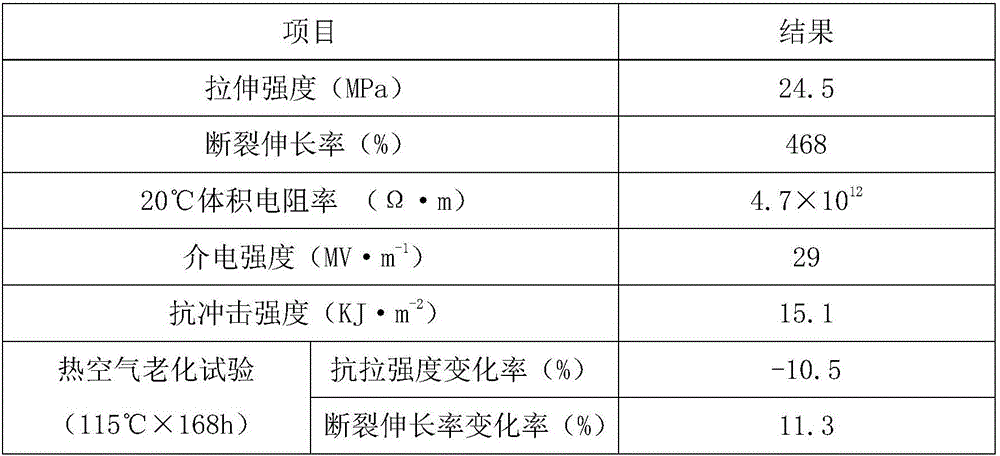

Image

Examples

Embodiment Construction

[0011] A high elasticity and high tenacity polypropylene cable material for communication, made of the following raw materials in weight (kg): Atactic polypropylene 80, thermoplastic elastomer SEEPS 30, annular butylene terephthalate 23, nanofiber Plain whisker 20, coumarone resin 17, hydroxyaluminum distearate 9, siliceous shale 25, diisodecyl phthalate 20, asbestos tailings 26, cadmium stearate 3, fluff powder 12, Basic magnesium sulfate whisker 13, volcanic ash 20.

[0012] A preparation method of a high-elasticity high-toughness polypropylene cable material for communication, comprising the following steps:

[0013] (1) Mix siliceous shale, asbestos tailings and volcanic ash evenly, pulverize, sieve, calcinate at 720-790°C for 1-2h, cool to room temperature and add the calcined powder according to the solid-to-liquid ratio of 1:3-4 Put it into a sulfuric acid solution with a mass fraction of 20%, heat it in a water bath to 40-50°C, soak it for 3-6 hours, let it cool down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com