Modified TPU abrasive sealing materials, production and use thereof

A technology of sealing materials and elastomer materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of unsatisfactory corrosion resistance and aging resistance, unable to meet the use requirements of working conditions, poor elasticity and rigidity, etc. problems, to achieve the effects of chemical stability and environmental resistance, high elastic compression set, and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

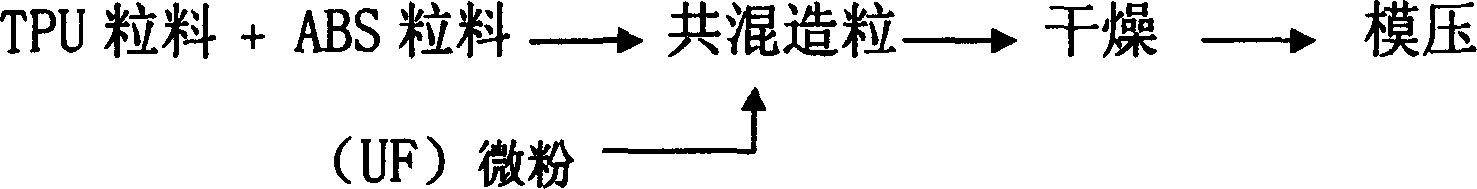

[0040] TPU pellets are mixed with ABS (acrylonitrile / butadiene / styrene copolymer) pellets to prepare shaft sleeve seals for seawater pumps. TPU pellets and ABS pellets are used as main materials, and ultrafine powder is used as auxiliary materials. After blending, granulation, drying, and molding, a sealing material suitable for seawater pump shaft sleeves is produced. The composition and weight of the specific material are as follows:

[0041] TPU pellets 100 parts

[0042] ABS pellets 20 parts

[0043] Superfine powder 15 parts

[0044] The above two materials are prepared according to the following manufacturing process:

[0045]

[0046] 1. First, mix TPU pellets and ABS pellets according to the predetermined ratio;

[0047] 2. Add 15 parts of ultrafine (UF) micropowder to the ingredients;

[0048] 3. Blend and granulate TPU pellets and ABS pellets; the blending process conditions are:

[0049] The raw material is dried at 100°C;

[0050] Blending temperature I: 1...

Embodiment 2

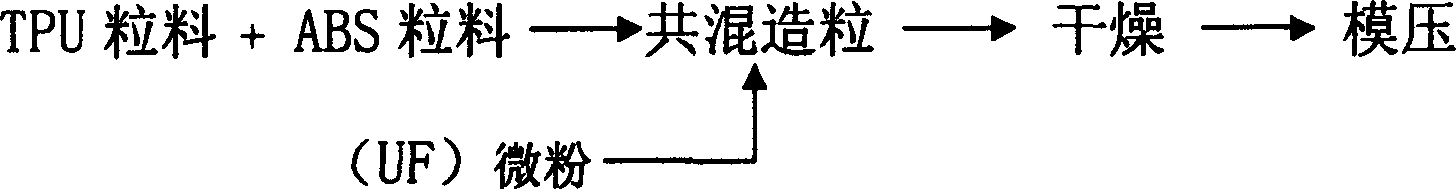

[0064] TPU pellets are mixed with ABS (acrylonitrile / butadiene / styrene copolymer) pellets to prepare shaft sleeve seals for seawater pumps. TPU pellets and ABS pellets are used as main materials, and ultrafine powder is used as auxiliary materials. After blending, granulation, drying, and molding, a sealing material suitable for seawater pump shaft sleeves is produced. The composition and weight of the specific material are as follows:

[0065] TPU pellets 100 parts

[0066] ABS pellets 35 parts

[0067] 7 servings of superfine powder

[0068] The above two materials are prepared according to the following manufacturing process:

[0069]

[0070]1. First mix TPU pellets and ABS pellets according to the predetermined ratio;

[0071] 2. Add 7 parts of ultrafine (UF) micropowder to the ingredients of TPU pellets and ABS pellets;

[0072] 3. Blend and granulate TPU pellets and ABS pellets; the blending process conditions are:

[0073] (1) The raw material is dried at 100°C...

Embodiment 3

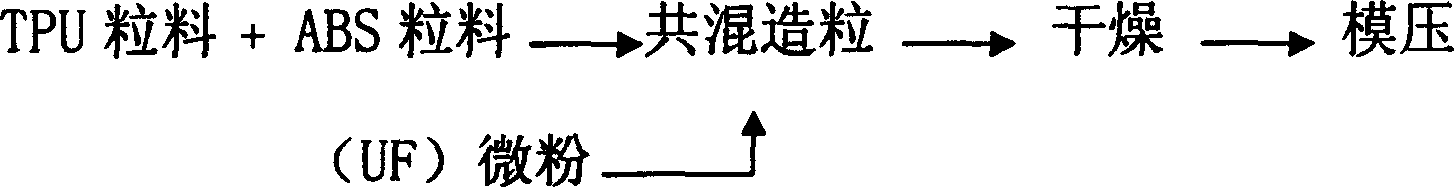

[0078] TPU pellets are mixed with ABS (acrylonitrile / butadiene / styrene copolymer) pellets to prepare shaft sleeve seals for seawater pumps. TPU pellets and ABS pellets are used as main materials, and ultrafine powder is used as auxiliary materials. After blending, granulation, drying, and molding, a sealing material suitable for seawater pump shaft sleeves is produced. The composition and weight of the specific material are as follows:

[0079] TPU pellets 100 parts

[0080] ABS pellets 25 parts

[0081] 9 servings of superfine powder

[0082] The above two materials are prepared according to the following manufacturing process:

[0083]

[0084] 1. First, mix TPU pellets and ABS pellets according to the predetermined ratio;

[0085] 2. Add 9 parts of ultrafine (UF) micropowder to the ingredients of TPU pellets and ABS pellets;

[0086] 3. Blend and granulate TPU pellets and ABS pellets; the blending process conditions are:

[0087] (1) The raw material is dried at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com