Crylic acid modified polyurethane dispersion wall coating and preparation method thereof

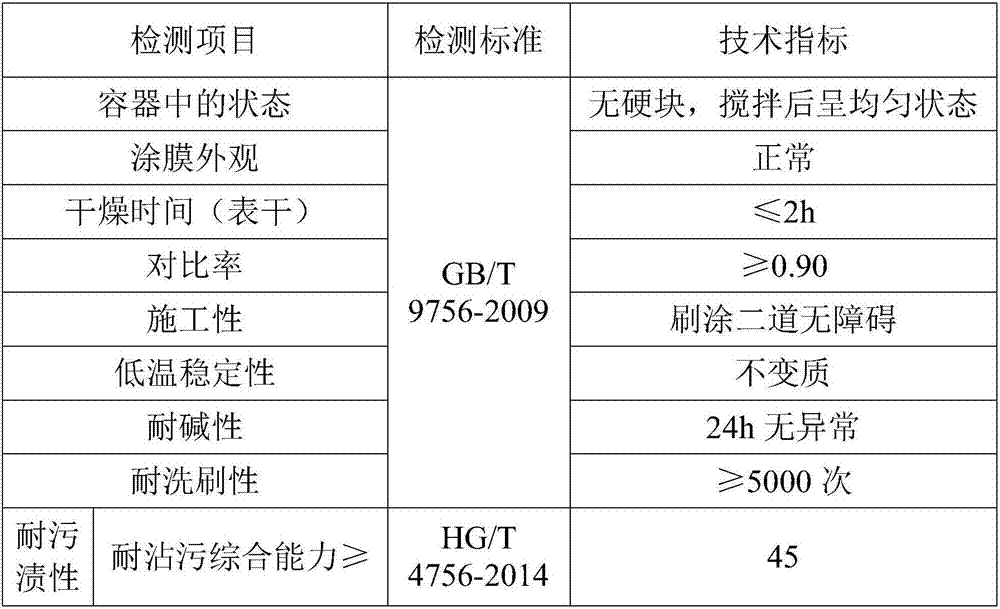

A technology of polyurethane dispersion and acrylic acid, which is applied in the field of coatings, can solve the problems of wall coatings such as strong odor, resistance to mold, and wear resistance, and achieve good mold resistance, VOC reduction, and high stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

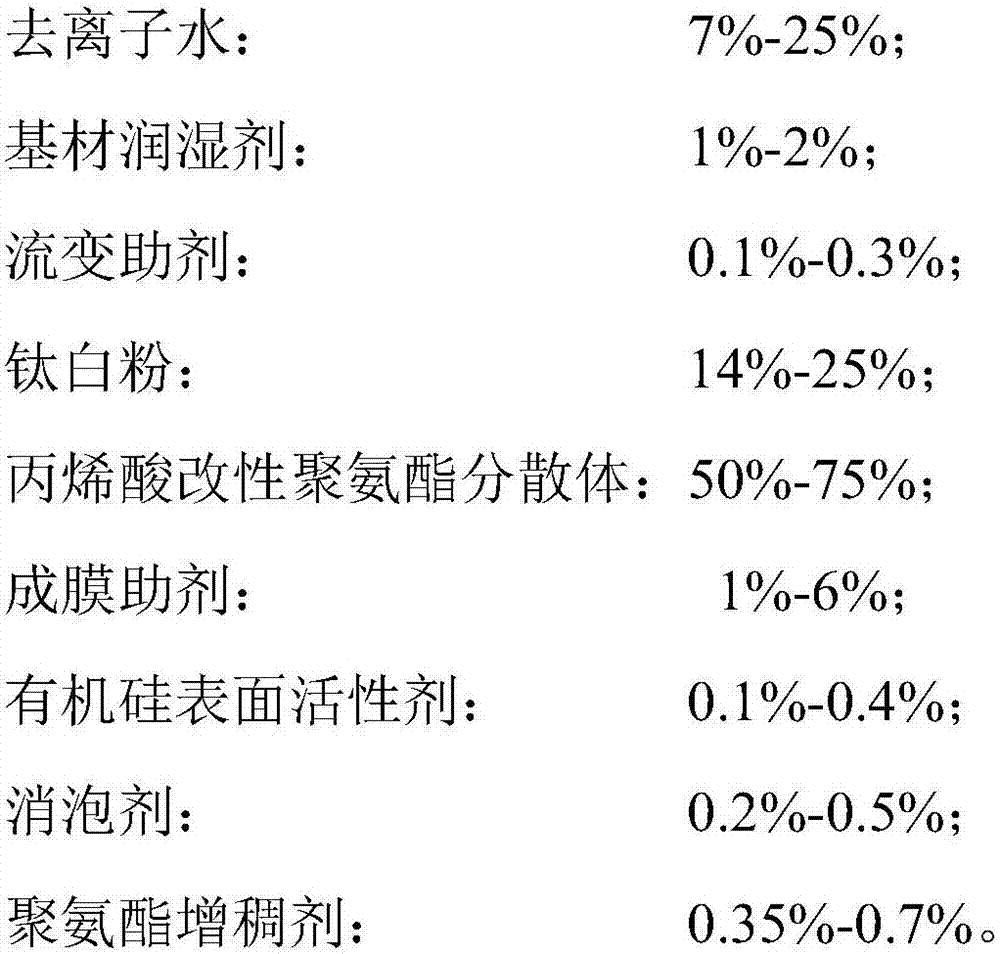

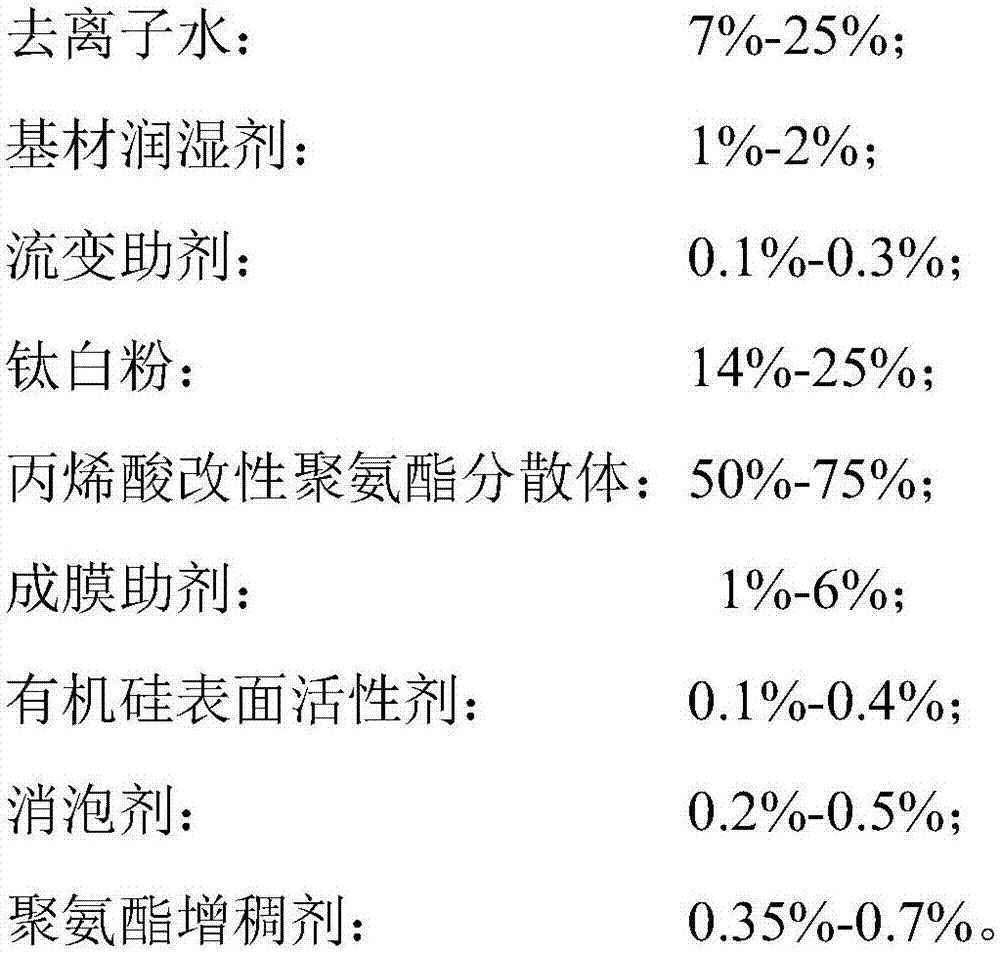

[0048] This embodiment provides an acrylic modified polyurethane dispersion wall coating. The raw materials of the acrylic modified polyurethane dispersion wall coating include the following components by weight percentage: deionized water: 11.7%; substrate wetting agent: 1.2%; rheological additive: 0.2%; titanium dioxide: 18% %; acrylic modified polyurethane dispersion: 64%; coalescent: 4%; silicone surfactant: 0.2%; defoamer: 0.3%; polyurethane thickener: 0.4%.

[0049]The present embodiment provides a kind of preparation method of acrylic acid modified polyurethane dispersion wall coating, may further comprise the steps at least:

[0050] Step 1: weighing each component according to the raw material ratio;

[0051] Step 2: Add deionized water into the material preparation tank, at a stirring speed of 300-500rpm, add substrate wetting agent and rheological additive in turn, and then stir at a speed of 300-500rpm for 3-5min;

[0052] Step 3: Add titanium dioxide to the abov...

Embodiment 2

[0055] This embodiment provides an acrylic modified polyurethane dispersion wall coating. The raw materials of the acrylic modified polyurethane dispersion wall coating include the following components by weight percentage: deionized water: 16.3%; substrate wetting agent: 1.3%; rheological additive: 0.2%; titanium dioxide: 25% %; acrylic modified polyurethane dispersion: 53%; coalescent: 3%; silicone surfactant: 0.3%; defoamer: 0.4%; polyurethane thickener: 0.5%.

[0056] The present embodiment provides a kind of preparation method of acrylic acid modified polyurethane dispersion wall coating, as described in embodiment 1, for saving space, no longer repeat them here.

Embodiment 3

[0058] This embodiment provides an acrylic modified polyurethane dispersion wall coating. The raw materials of the acrylic modified polyurethane dispersion wall coating include the following components by weight percentage: deionized water: 18.9%; substrate wetting agent: 1.2%; rheological additive: 0.2%; titanium dioxide: 15%; Acrylic modified polyurethane dispersion: 60%; coalescent: 3.5%; silicone surfactant: 0.3%; defoamer: 0.4%; polyurethane thickener: 0.5%.

[0059] The present embodiment provides a kind of preparation method of acrylic acid modified polyurethane dispersion wall coating, as described in embodiment 1, for saving space, no longer repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com