Polyurethane foam insulation material and preparation method thereof

A technology of polyurethane foam and thermal insulation materials, applied in the field of polyurethane foam thermal insulation materials, can solve the problems of foam brittleness, poor fluidity, high viscosity of the system, etc., and achieve excellent ultraviolet reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

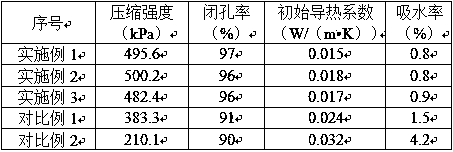

Examples

Embodiment 1

[0033] A polyurethane foam insulation material, which is composed of the following components in parts by weight: 90 parts of polyurethane prepolymer, 120 parts of isocyanate, 18 parts of spirulina small molecule peptide, 10 parts of phase change material microcapsules, and 20 parts of deionized water , 5 parts of stearic acid modified perlite, 4 parts of epoxyacetyl ricinoleic acid methyl ester.

[0034] The preparation method of above-mentioned polyurethane prepolymer, it may further comprise the steps:

[0035] (1) Weigh the following raw materials in parts by weight: 80 parts of polymer polyol, 10 parts of flame retardant, 5 parts of neutralizing agent, 3 parts of polyaspartic acid ester, 10 parts of modified nano titanium dioxide, 18 parts of isocyanate ; The polymer polyol is polyester polyol or polyether polyol; The isocyanate is one of toluene diisocyanate, diphenylmethane diisocyanate, multiple methylene polyphenyl polyisocyanate or A mixture of two or more; the flam...

Embodiment 2

[0046] A polyurethane foam insulation material, which is composed of the following components in parts by weight: 100 parts of polyurethane prepolymer, 110 parts of isocyanate, 15 parts of spirulina small molecule peptide, 8 parts of phase change material microcapsules, and 30 parts of deionized water , 8 parts of stearic acid modified perlite, 5 parts of epoxyacetyl ricinoleic acid methyl ester.

[0047] The preparation method of above-mentioned polyurethane prepolymer, it may further comprise the steps:

[0048] (1) Weigh the following raw materials in parts by weight: 70 parts of polymer polyol, 50 parts of flame retardant, 8 parts of neutralizing agent, 2 parts of polyaspartate, 12 parts of modified nano titanium dioxide, 20 parts of isocyanate ; The polymer polyol is polyester polyol or polyether polyol; The isocyanate is one of toluene diisocyanate, diphenylmethane diisocyanate, multiple methylene polyphenyl polyisocyanate or A mixture of two or more; the flame retardan...

Embodiment 3

[0059] A polyurethane foam insulation material, which is composed of the following components in parts by weight: 80 parts of polyurethane prepolymer, 100 parts of isocyanate, 20 parts of spirulina small molecule peptide, 5 parts of phase change material microcapsules, and 15 parts of deionized water , 7 parts of stearic acid modified perlite, 3 parts of epoxyacetyl ricinoleic acid methyl ester.

[0060] The preparation method of above-mentioned polyurethane prepolymer, it may further comprise the steps:

[0061] (1) Weigh the following raw materials in parts by weight: 90 parts of polymer polyol, 15 parts of flame retardant, 10 parts of neutralizing agent, 1 part of polyaspartic acid ester, 15 parts of modified nano titanium dioxide, 15 parts of isocyanate ; The polymer polyol is polyester polyol or polyether polyol; The isocyanate is one of toluene diisocyanate, diphenylmethane diisocyanate, multiple methylene polyphenyl polyisocyanate or A mixture of two or more; the flame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com