High-strength cable material used for railway vehicle, and preparation method thereof

A rail vehicle, high-strength technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as inability to meet, and achieve the effects of good thermal stability, excellent electrical insulation performance, and good heat aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

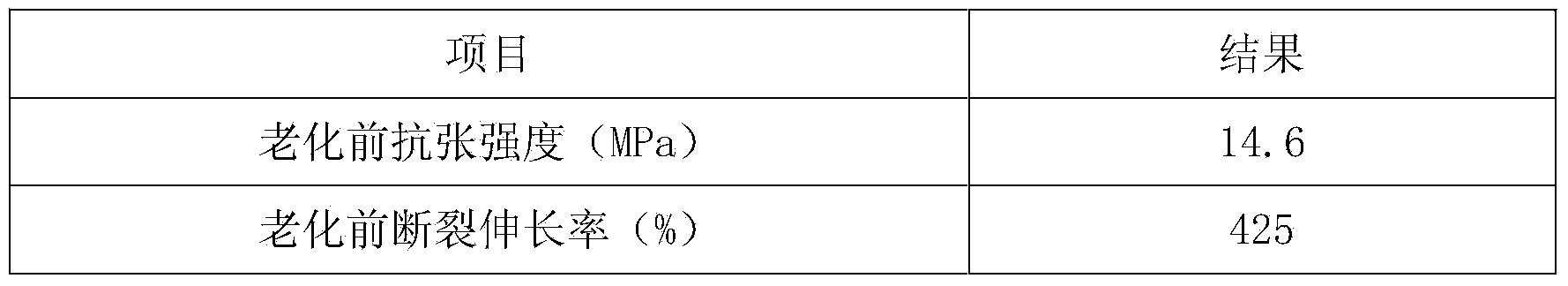

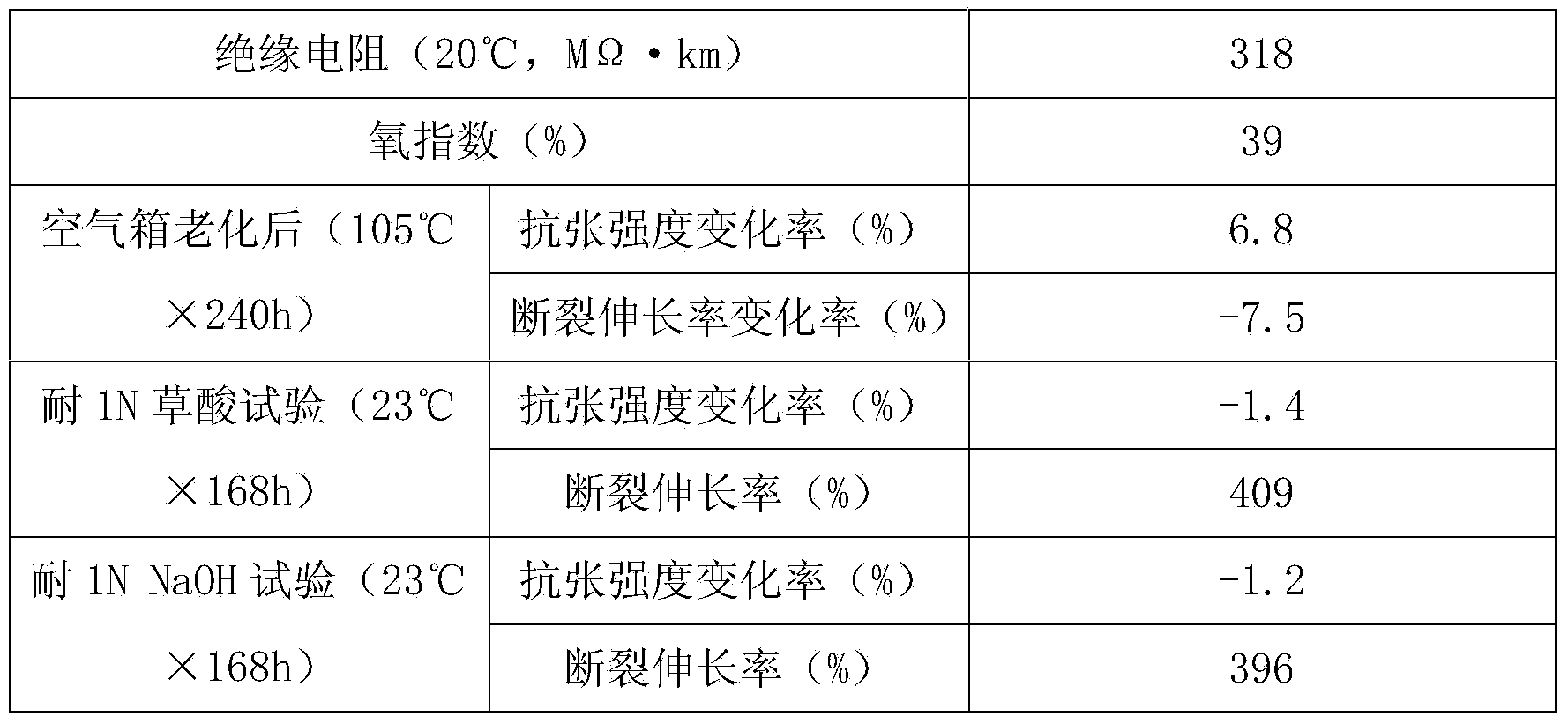

[0013] A high-strength cable material for rail vehicles, made of the following raw materials in parts by weight: polyphenylene sulfide 95, aromatic polycarbonate 50, ethylene-methyl acrylate-glycidyl methacrylate terpolymer 30, Diphenylmethane diisocyanate 6, bis(4-carboxyphenyl) phenylphosphine oxide 14, zinc aluminate 12, magnesium hydroxide 25, basalt short fiber 10, methacryloxypropyl trimethoxysilane 2.5 , Three (mercaptoethyl stearate) antimony 4, calcium stearate 2, barium stearate 2, erucamide 6, polyethylene wax 4, calcined clay 18, basic magnesium chloride whiskers 12, precipitated silica 25. Modified stone powder 16, methyl epoxy acetyl ricinoleate 12, antioxidant 1222 2.5;

[0014] The preparation method of the modified stone powder is as follows: (1) Weigh coke gemstones, volcanic stones, and attapulgite at a weight ratio of 5:3:2, mix them uniformly, calcinate at 780°C for 1.5h, cool naturally to room temperature, pulverize, pass Sieve, stand-by; (2) get the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com