Modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and preparation method thereof

A technology of boehmite nitrile and composite cable material, applied in rubber insulators, organic insulators, etc., can solve the problems of restricting the safety and service life of cables, inability to balance hardness and toughness, and intolerant of humidity, cold and heat, etc. The effect of improving aging performance, improving mechanical properties and improving electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

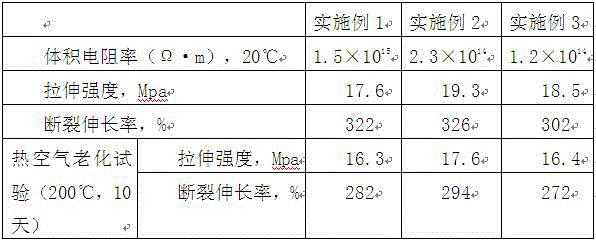

Examples

Embodiment 1

[0016] A modified pseudo-boehmite nitrile rubber composite cable material, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 50, pseudo-boehmite 30, thermoplastic polyurethane elastomer 20, brominated isobutylene - p-Methylstyrene Copolymer 30, Neopentyl Glycol Dibenzoate 10, Calcium Stearate 6, 2-Ethylhexyl Diphenyl Phosphate 30, Zinc Oxide 3, Chloropropyl Triethoxy Silane 6, terpene phenolic resin 4, pine tar 7, nanometer calcium carbonate 30, mixed caprylic monoglyceride 7, epoxyacetyl ricinoleic acid methyl ester 3, magnesium methacrylate 5, 2,4-dichloroperoxide Benzoyl Oxide 1, Active Silicon Micropowder 6, Nano Tungsten Oxide 5, Talc Powder 12, Cao Carbon Black 8.

[0017] A preparation method of modified pseudo-boehmite nitrile rubber composite cable material, comprising the following steps:

[0018] (1) Mix terpene phenolic resin, pine tar, active silicon micropowder, nano-tungsten oxide, talcum powder, and cascading carbon bla...

Embodiment 2

[0023] A modified pseudo-boehmite nitrile rubber composite cable material, characterized in that it is prepared from the following raw materials in parts by weight (kg): 55% nitrile rubber, 32.5% pseudo-boehmite, 25% thermoplastic polyurethane elastomer , Brominated isobutylene-p-methylstyrene copolymer 35, neopentyl glycol dibenzoate 11, calcium stearate 7, 2-ethylhexyl diphenyl phosphate 35, zinc oxide 4, chloropropyl Triethoxysilane 7, terpene phenolic resin 5, pine tar oil 8, nano calcium carbonate 32, mixed caprylic monoglyceride 8, epoxyacetyl ricinoleic acid methyl ester 4.5, magnesium methacrylate 6, 2, 4 -Dichlorobenzoyl peroxide 1.5, active silica powder 7.5, nano tungsten oxide 6.5, talcum powder 14, cassava carbon black 9.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] A modified pseudo-boehmite nitrile rubber composite cable material, which is characterized in that it is prepared from the following raw materials in parts by weight (kg): nitrile rubber 60, pseudo-boehmite 35, thermoplastic polyurethane elastomer 30 , Brominated isobutylene-p-methylstyrene copolymer 40, neopentyl glycol dibenzoate 12, calcium stearate 8, 2-ethylhexyl diphenyl phosphate 40, zinc oxide 5, chloropropyl Triethoxysilane 8, terpene phenolic resin 6, pine tar 9, nanometer calcium carbonate 34, mixed caprylic monoglyceride 9, epoxyacetyl ricinoleic acid methyl ester 6, magnesium methacrylate 7, 2, 4 - Dichlorobenzoyl peroxide 2, activated silicon micropowder 9, nano tungsten oxide 8, talcum powder 16, cassava carbon black 10.

[0027] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com