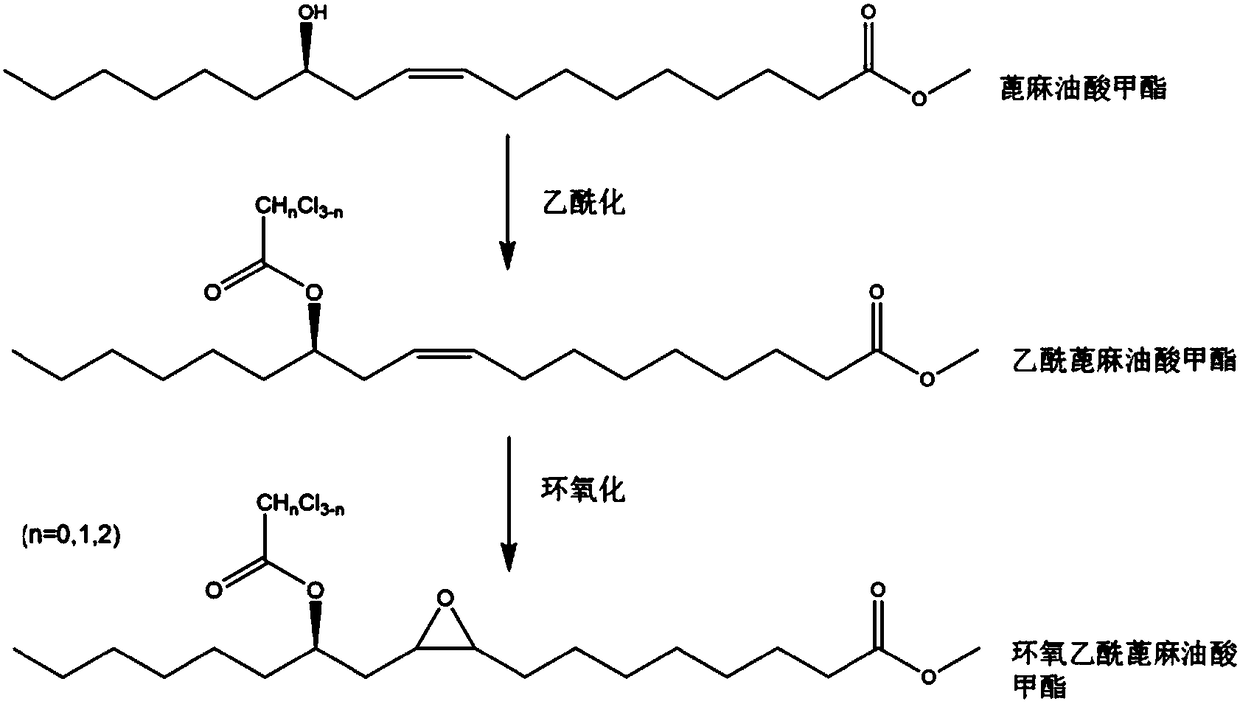

Method for improving compatibility of epoxidized methyl acetylricinolate plasticizer and PVC (Polyvinyl Chloride) resin

A technology of epoxy acetyl castor and PVC resin, which is applied in the direction of organic chemistry, can solve the problems of reduced plasticizer compatibility, high plasticizing temperature, and poor softness of PVC finished products, so as to reduce the plasticizing temperature, Effect of improving flexibility, improving durability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 36 parts of monochloroacetic anhydride and 2 parts of phosphoric acid to 100 parts of methyl ricinoleate at 40°C and nitrogen atmosphere, and then react at 65°C for 2 hours. After the reaction, use 1.5% sodium carbonate. The organic layer is washed with the solution and distilled water until the pH of the washed water is 5.5, and then the water is distilled off under reduced pressure to obtain methyl acetylricinoleate;

[0022] (2) Take 40 parts of 30% hydrogen peroxide, 15 parts of formic acid, and 0.5 parts of concentrated sulfuric acid to prepare peroxy acid. At 40℃, add 100 parts of methyl acetyl ricinoleate and 25 parts of benzene. Add dropwise for 30 minutes, and then react at 45°C for 3 hours. After the reaction, the lower layer of acid is separated, and the upper organic layer is washed with 1.5% sodium carbonate solution and distilled water, until the pH of the washed water is 5.5, then reduce Pressure distillation to remove water to obtain methyl epoxyace...

Embodiment 2

[0025] (1) Add 60 parts of monochloroacetic anhydride and 3 parts of p-toluenesulfonic acid to 100 parts of methyl ricinoleate under 40°C and nitrogen atmosphere, and then react at 65°C for 4 hours. After the reaction, use 1.5% respectively. Wash the organic layer with sodium bicarbonate solution and distilled water to pH=6, and then distill off the water under reduced pressure to obtain methyl acetyl ricinoleate;

[0026] (2) Take 45 parts of 30% hydrogen peroxide, 18 parts of formic acid, and 0.8 parts of concentrated sulfuric acid to make peroxy acid. At 45°C, add 100 parts of methyl acetyl ricinoleate and 30 parts of toluene. To the mixture, add dropwise for 60 minutes, and then react at 45°C for 4 hours. After the reaction, the lower layer of acid is separated, and the upper organic layer is washed with 2% sodium bicarbonate solution and distilled water, until the wash water pH=6, and then reduce Pressure distillation to remove water to obtain methyl epoxyacetyl ricinoleate....

Embodiment 3

[0029] (1) Mix 100 parts of ricinoleic acid methyl ester and 48 parts of chloroform uniformly, add dropwise a mixture of 80 parts of trichloroacetyl chloride and 33 parts of pyridine to the reactant under a nitrogen atmosphere at 0°C, and then react at 10°C After 12 hours, after the reaction, 400 parts of ice water were added to wash, and then the organic layer was washed with 3% sodium bicarbonate solution and distilled water to pH=6, and then the water was distilled under reduced pressure to obtain acetyl ricinoleic acid methyl ester;

[0030] (2) Take 50 parts of 30% hydrogen peroxide, 20 parts of acetic acid, and 1 part of concentrated sulfuric acid to make peroxy acid. At 48℃, add 100 parts of methyl acetyl ricinoleate and 35 parts of benzene. Add dropwise for 90 minutes, and then react at 48°C for 5 hours. After the reaction, the lower layer of acid is separated, and the upper organic layer is washed with 3% sodium bicarbonate solution and distilled water, until the pH of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com