Preparation method of high viscosity index poly alpha olefine synthetic oil

An olefin synthesis oil, high viscosity technology, applied in the direction of inter-unsaturated hydrocarbon addition hydrocarbon production, chemical instruments and methods, hydrocarbon purification/separation, etc., can solve the problems such as the preparation and regeneration scheme of the chromium catalyst, and achieve excellent The effect of thermo-oxidative stability, easy process operation and good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

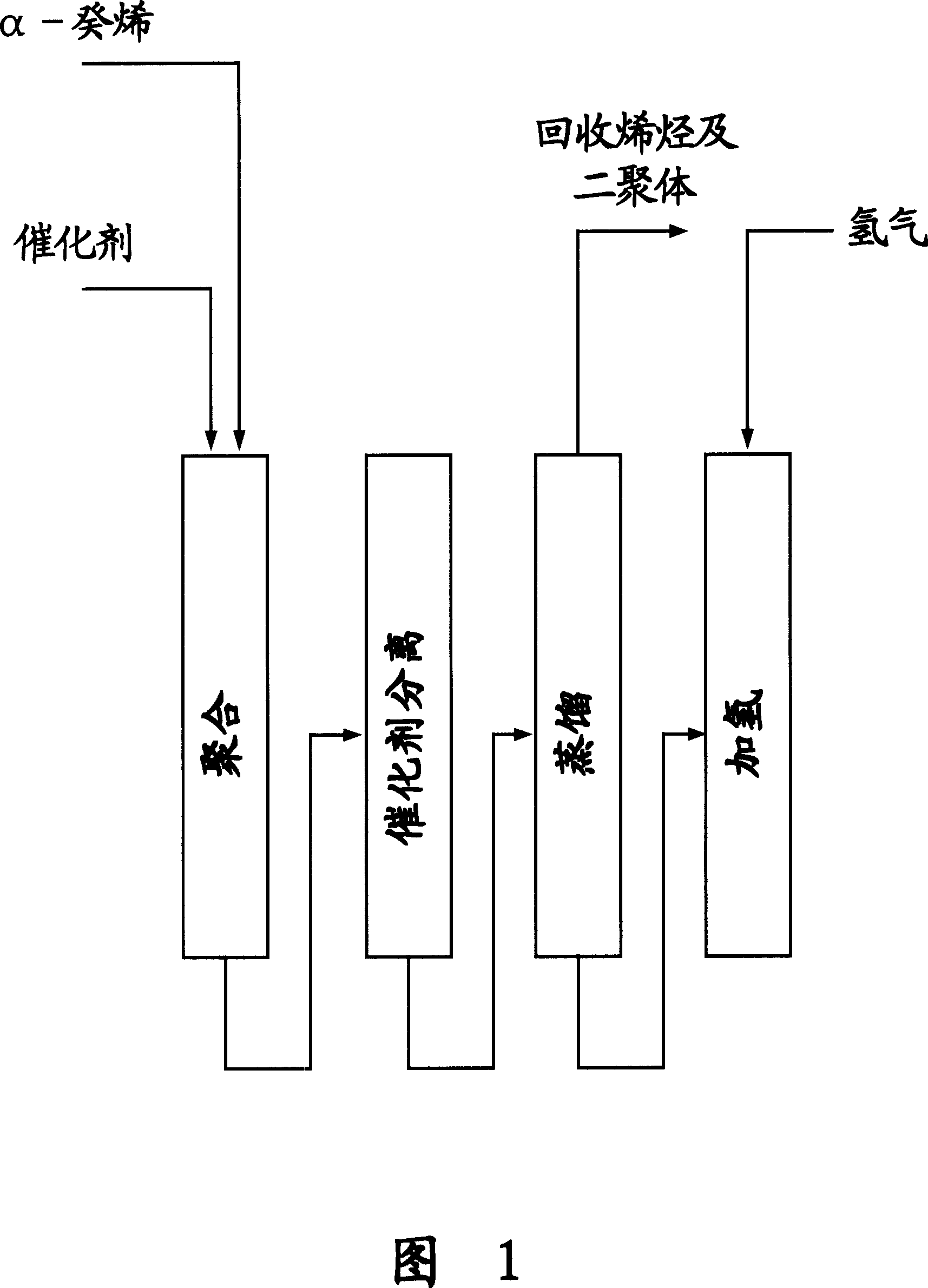

Image

Examples

Embodiment 1

[0038] This example illustrates the preparation of the chromium catalyst employed in the present invention.

[0039] Weigh 9g of chromium acetate aqueous solution Cr(CH 3 COO) 3 (Shanghai Laize Fine Chemical Factory produces, and concentration is 48-53%), it is dissolved in the acetic acid of 100ml 40-50 ℃, then with chromium solution and 100g, particle size is 8-12 purpose silica gel (by Qingdao Ocean Chemical Co., Ltd. Factory production) mixed, stirred at room temperature for 30 minutes, then dried at room temperature and set aside.

[0040] Take the dried silica gel carrier and put it into a tubular reaction furnace. Under the protection of nitrogen, start to heat up. When the furnace temperature rises to 200°C, keep the temperature for 0.5h to remove the solvent. Replace nitrogen with air, continue to raise the furnace temperature to 600°C for 12 hours, then switch the air to nitrogen, under the protection of nitrogen, cool the catalyst to 300°C, pass in reducing gas CO...

Embodiment 2

[0042] This example illustrates the preparation of the chromium catalyst employed in the present invention.

[0043] Weigh 3.5g chromium acetate Cr(CH 3 COO) 3 (produced by Beijing Chemical Plant), dissolve it in 10ml of 40-50°C acetic acid and water mixture (mixing ratio is 3:7, volume ratio), then add 40-50°C acetic acid 70ml, mix chromium solution with 80g , particle size of 8-12 mesh silica gel mixed, stirred at room temperature for 30 minutes, then dried at room temperature, set aside.

[0044] Take the dried silica gel carrier and put it into a tubular reaction furnace. Under the protection of nitrogen, start to heat up. When the furnace temperature rises to 250°C, keep the temperature for 0.5h to remove the solvent. Replace nitrogen with air, continue to raise the furnace temperature to 550°C for 12 hours, then switch the air to nitrogen, under the protection of nitrogen, cool the catalyst to 350°C, pass in reducing gas CO, keep the temperature for 3 hours, and remove...

Embodiment 3-9

[0046] This embodiment illustrates: adopt the method described in the present invention to prepare polyalpha-olefin synthetic oil.

[0047] Add 2kg α-decene raw material (produced by the Czech Republic) in the tank reactor, still temperature is raised to the reaction temperature of setting under continuous stirring, adds the chromium catalyst after the activation, the α-decene raw material and catalyzer The weight ratio is 100:1. Under the protection of nitrogen, react for 10h, release the oligomer, and filter off the catalyst. The resulting reaction product was distilled at 180°C under normal pressure to separate the light components in the product. See Table 1 for the experimental results.

[0048] example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com