Catalyst for preparation of decyl alcohols by gas-phase hydrogenation of decylenaldehydes and preparation method thereof

A catalyst, the technology of decenal, which is applied in the field of catalyst and preparation of decenal gas-phase hydrogenation to isodecyl alcohol, to achieve the effects of uniformity, increase of external surface area and reduction of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

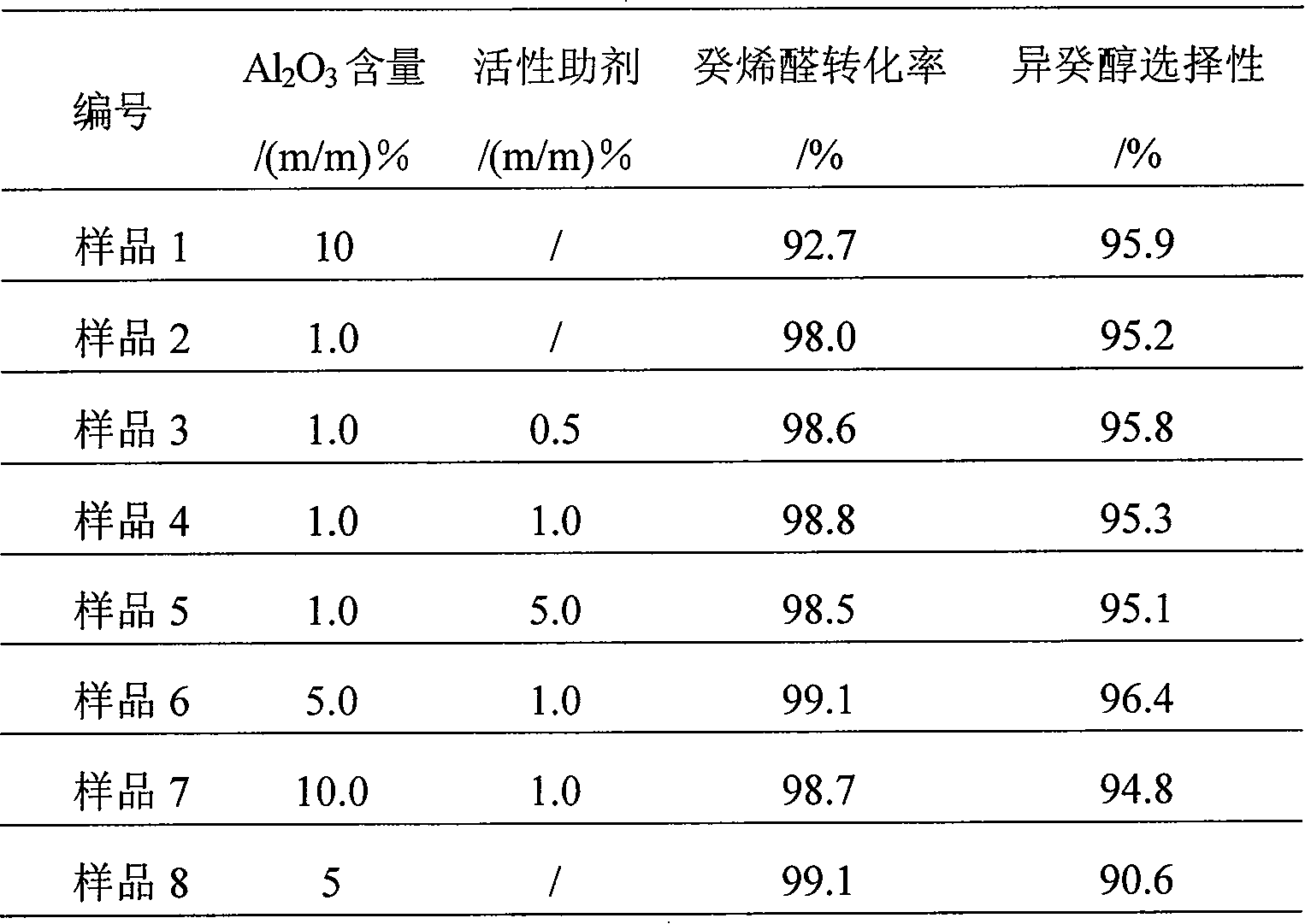

Examples

example 1

[0012] Take 500mL of 1.2M copper nitrate solution and 1710mL of 1.2M zinc nitrate solution and mix them. Co-precipitate the mixed solution and sodium carbonate solution in a sedimentation tank with stirring. Stir and age for 30 minutes, add about 23.8g of alumina after washing, filter, dry, and granulate. The dried particles are calcined at 320°C-400°C for 3-4h, and then pressed into tablets to obtain catalyst sample 1.

example 2

[0014] Take 1000mL of 1.2M copper nitrate solution and 2000mL of 1.2M zinc nitrate solution and mix them. Co-precipitate the mixed solution and sodium carbonate solution in a sedimentation tank with stirring. Stir and age for 30 minutes, add about 3.0 g of alumina after washing, filter, dry, and granulate. The dried particles are calcined at 320°C-400°C for 3-4 hours, and then pressed into tablets to obtain catalyst sample 2.

example 3

[0016] Take 1000mL of 1.2M copper nitrate solution and 2000mL of 1.2M zinc nitrate solution and mix them. Co-precipitate the mixed solution and sodium carbonate solution in a sedimentation tank with stirring. Stir and age for 30 minutes, add about 3.0g of alumina and 2.0g of coagent after washing, then filter, dry, and granulate. The dried particles are roasted at 320°C-400°C for 3-4h, and then pressed into tablets to obtain Catalyst Sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com