Catalyst composite for dehydrogenation of hydrocarbons and its preparation method

A technology for dehydrogenation catalysts and composites, which can be used in catalyst activation/preparation, hydrocarbons, hydrocarbons, etc., and can solve problems such as undocumented alkali metal combined uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

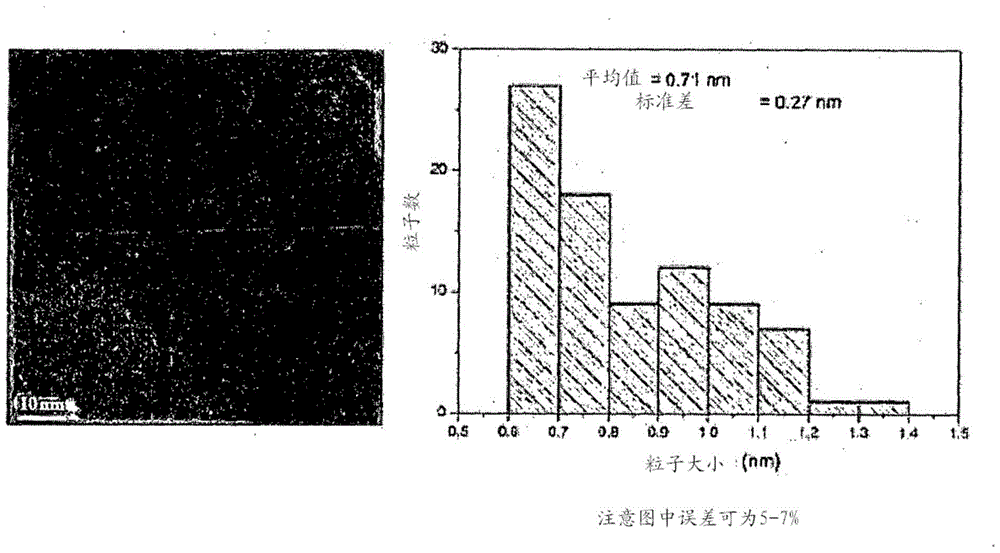

[0122] Preparation of Catalyst Support

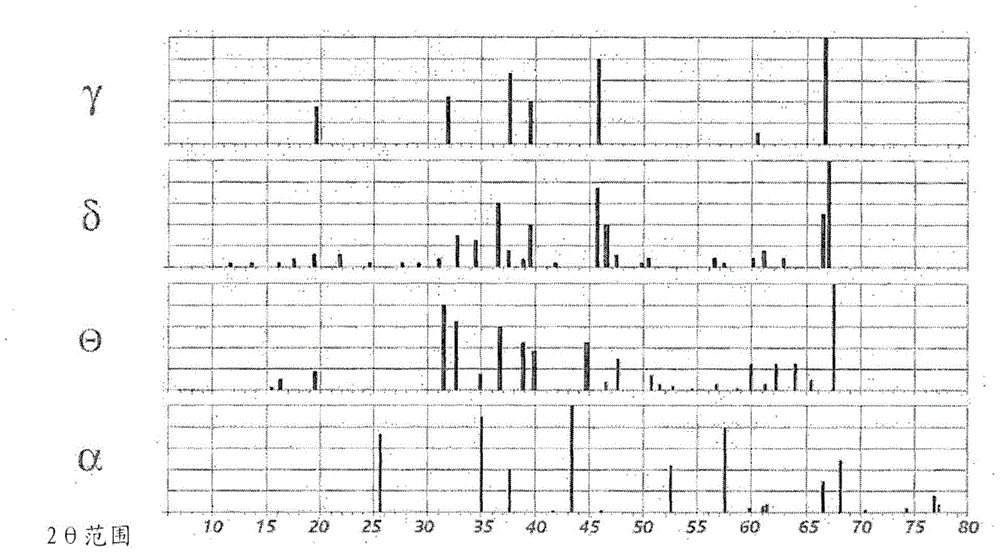

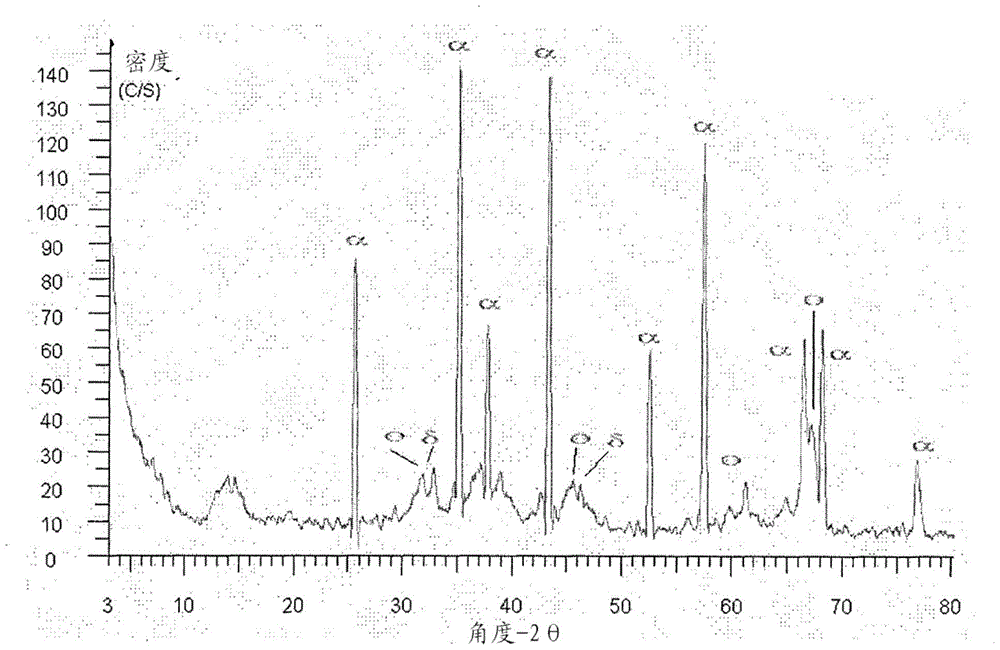

[0123]Inert alpha alumina nuclei with an average diameter of 1.2 mm were used as cores. The particles were grown by coating activated alumina powder and binder in a rotating pan to an average diameter of 1.8 mm. The material is then hydrated to gain strength and dried. This is followed by heating at 850°C in the presence of air. Activated alumina, once heated to 850°C, produces a mixture of delta and theta alumina phases (Reference: Industrial Alumina Chemicals, C. Mishra, ACS Monograph, 1986).

Embodiment 2

[0125] Preparation of Catalyst Compounds for Catalysts

[0126] Using a two-step process to impregnate the spherical coated alumina support prepared in Example 1, by employing the incipient wetness technique, catalyst composites were prepared with the following mixture:

[0127] Table 1:

[0128]

[0129] In the first impregnation step, use LiNO 3 solution, impregnating the carrier by wet impregnation, after which the impregnated carrier was dried and calcined at 640°C / 4h. The second impregnation is performed with a salt solution of Pt, Sn, Ir and Na. The precursor used is H 2 PtCl 6 , SnCl 2 , IrCl 3 , NaCl, HCl and TMA. The re-impregnated support was dried again, calcined, and then subjected to a controlled dehalogenation step to reduce its chlorine content to 0.20% by weight.

[0130] Measurement data:

[0131] 1. The influence of the presence of iridium on the bromine value

[0132] The bromine numbers of the catalysts prepared according to Examples 1 and 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com