Petroleum resin hydrogenation catalyst and preparation and application methods thereof

A technology of hydrogenation catalyst and petroleum resin, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of unfavorable production, high cost and high cost, Achieving the effect of low cost, improved hydrogenation activity and high proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

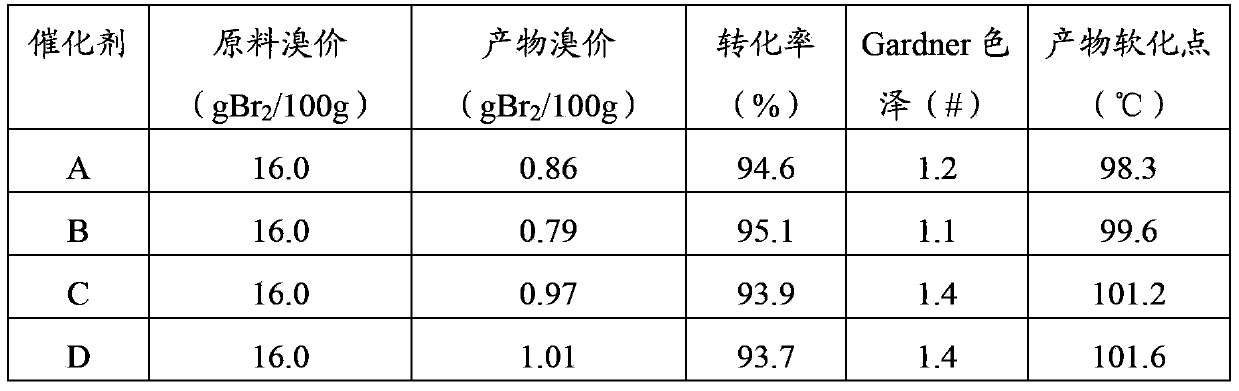

Embodiment 1

[0020] Weigh an appropriate amount of nickel nitrate, ammonium molybdate and silver nitrate and add them to deionized water to prepare 83 mL of mixed solution as the immersion solution. Weigh 100g of Al prepared according to the method of patent ZL02146005.1 2 O 3 -TiO 2 The carrier is added to the above-mentioned dipping solution for 4 hours at room temperature. After filtration, the solid was dried at a temperature of 120° C. for 10 hours, and then calcined at a temperature of 550° C. for 6 hours. The calcined solid was taken out and allowed to cool to room temperature naturally to obtain a catalyst A. Based on the total weight of the catalyst A, the content of Ni is 13.4% by weight, Mo is 6.7% by weight, and Ag is 1.2% by weight.

Embodiment 2

[0022] Weigh an appropriate amount of nickel nitrate, ammonium molybdate and silver nitrate and add them to deionized water to prepare 95 mL of mixed solution as the immersion solution. Weigh 100g of Al prepared according to the method of patent ZL02146005.1 2 O 3 -TiO 2 The carrier is added to the above-mentioned dipping solution for 4 hours at room temperature. After filtering, the solid was dried at a temperature of 120°C for 10 hours, and then calcined at a temperature of 550°C for 6 hours, and the calcined solid was taken out and allowed to cool to room temperature naturally to obtain a catalyst B. Based on the total weight of the catalyst B, the content of Ni is 16.4% by weight, Mo is 5.2% by weight, and Ag is 0.8% by weight.

Embodiment 3

[0024] Weigh an appropriate amount of nickel nitrate, ammonium molybdate and silver nitrate and add them to deionized water to prepare 102 mL of mixed solution as the immersion solution. Weigh 100g of Al prepared according to the method of patent ZL02146005.1 2 O 3 -TiO 2 The carrier is added to the above-mentioned dipping solution for 4 hours at room temperature. After filtration, the solid was dried at a temperature of 120° C. for 10 hours, and then calcined at a temperature of 550° C. for 6 hours. The calcined solid was taken out and allowed to cool to room temperature naturally to obtain a catalyst C. Based on the total weight of the catalyst C, the content of Ni is 19.7% by weight, Mo is 3.5% by weight, and Ag is 1.4% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com