Distillate oil hydrogen refining catalyst

A hydrorefining and catalyst technology, applied in the field of monoolefins, can solve problems such as olefin loss, and achieve the effects of reducing olefin saturation, reducing loss, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

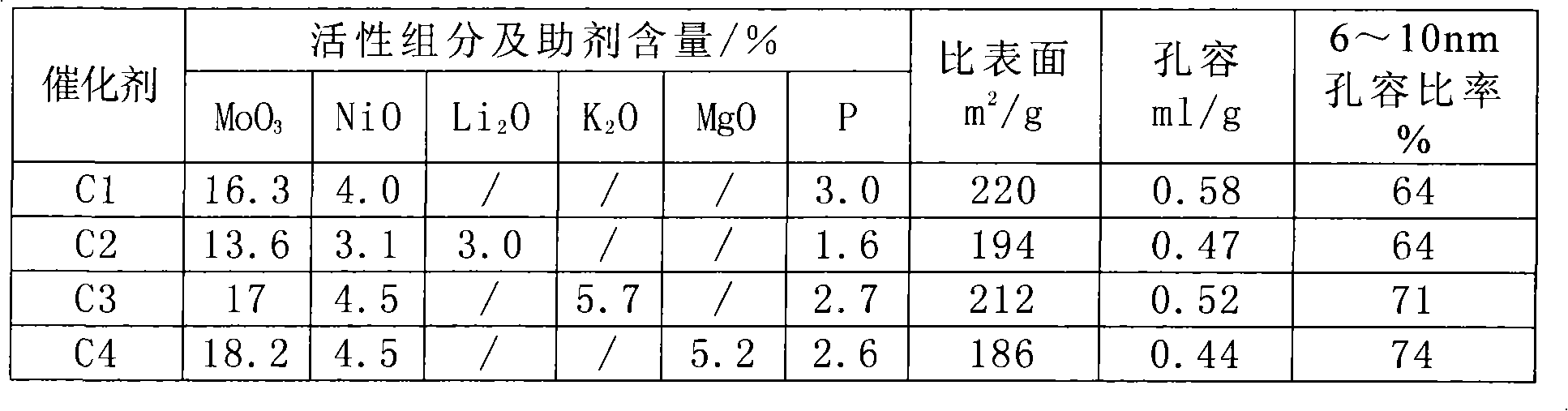

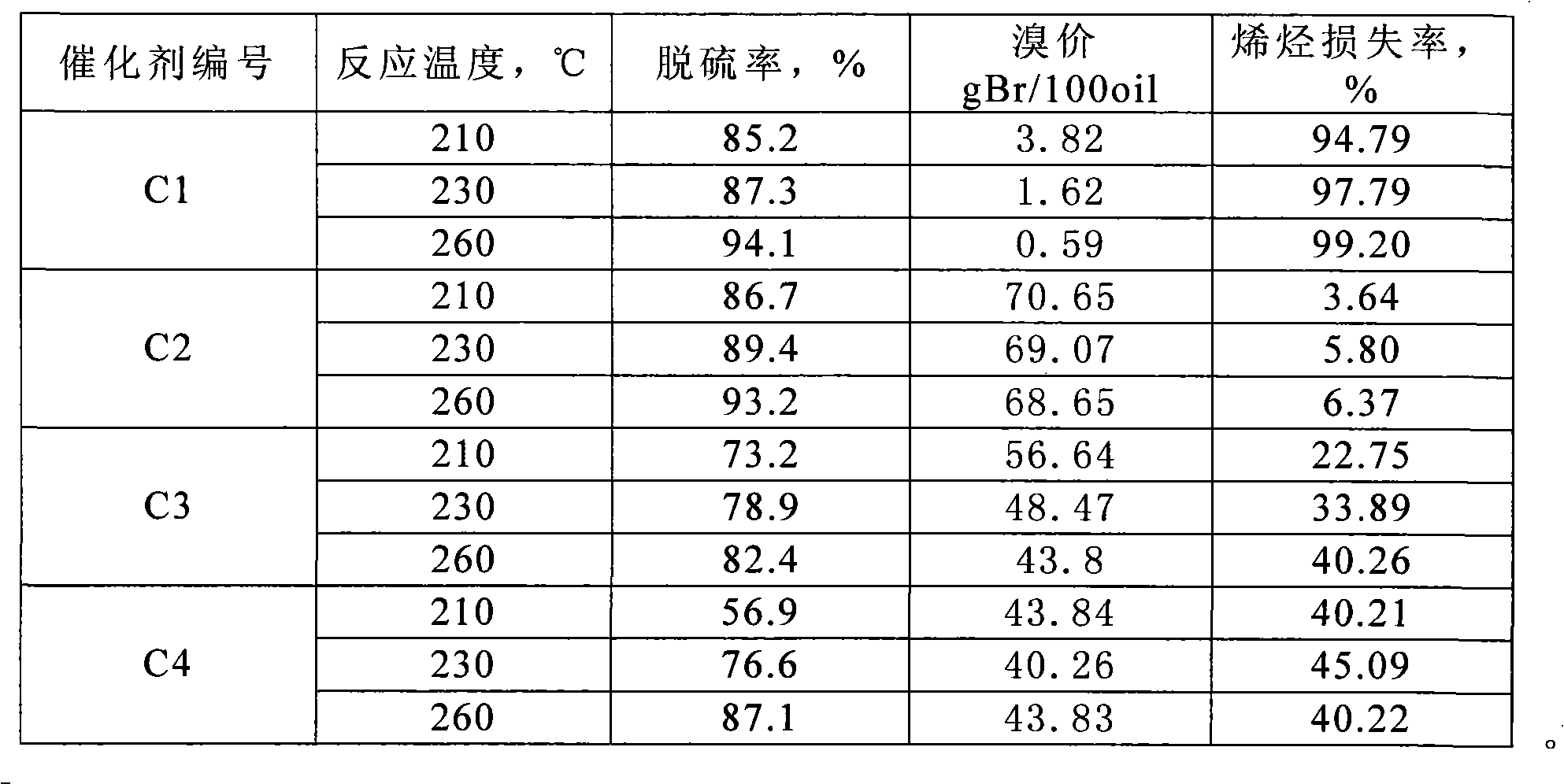

Examples

Embodiment 1

[0020] Take 1000g of pseudo-boehmite dry powder, add 25g of acetic acid, 21g of citric acid, 25g of scallop powder and 600ml of deionized water, knead and extrude into strips. Dry at 110°C for 4 hours, and bake at 850°C for 4 hours to obtain carrier z1.

Embodiment 2

[0022] Take 1000g of pseudo-boehmite, add 25g of acetic acid, 25g of citric acid, 25g of turnip powder, 18g of orthophosphoric acid and 700ml of deionized water, mix and extrude into strips. Dry at 110°C for 4 hours, and bake at 850°C for 4 hours to obtain carrier z2.

Embodiment 3

[0024] Take 800g of pseudo-boehmite dry powder, 240g of magnesium carbonate dry mix evenly, add 25g of acetic acid, 21g of citric acid, 25g of scallop powder and 600ml of deionized water, mix and extrude to form. Dry at 110°C for 4 hours, and bake at 960°C for 4 hours to obtain carrier z3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com