Method for removing unsaturated hydrocarbon and thiophene from coking benzene

A technology for coking benzene and unsaturated, applied in the direction of organic chemistry, chemical change purification/separation, etc., can solve problems such as thiophene desulfurization, and achieve the effect of easy implementation, simple and easy reaction and separation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

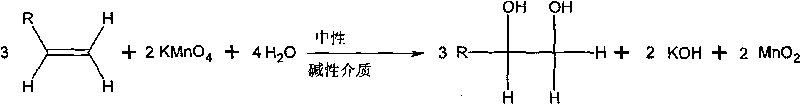

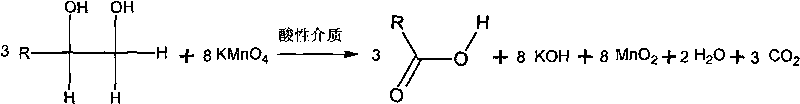

Method used

Image

Examples

Embodiment 1

[0021] A kind of coking refined benzene after extraction and refining, the benzene content is more than 99.5%, the appearance is colorless, transparent liquid, the colorimetry of acid washing, bromine value and total sulfur content all do not meet the national standard GB / T 2283 "Coking benzene" The quality standard of medium and high-quality products. According to GB / T 8035 "Determination Method for Pickling Colorimetry of Coking Benzene Products", the colorimetry of the pickled refined benzene is determined to be greater than 2g / l; according to GB / T 1815 "Determination of Bromine Value of Benzene Products", the determination of coking The bromine value of refined benzene is 0.07g / 100ml; according to GB / T 3208 "Microcoulombic Determination of Total Sulfur in Benzene Products", the total sulfur content of coking refined benzene is 65.3mg / kg; according to GB / T 14327 "The content of thiophene in benzene Determination method ", the content of thiophene in coking refined benzene w...

Embodiment 2

[0031] The sample and basic treatment steps are the same as in Example 1. Take 100 ml of coking refined benzene and mix with 20 ml of 0.063 mol / l potassium permanganate aqueous solution, add 1 ml of glacial acetic acid, adjust the pH value of the mixed solution to about 3, and stir at room temperature for 1 Hours, after standing for stratification, take out the benzene in the upper layer, wash with aqueous solution, the quality indicators of the coking refined benzene obtained are as follows: pickling colorimetry 0.3g / l, bromine value 0.028g / 100ml, total sulfur 52.0mg / kg, total sulfur Thiophene in 49.6mg / kg.

[0032] Coking refined benzene is mixed with 0.063mol / l potassium permanganate aqueous solution, the mixing volume ratio is 1:0.2, and stirred once under weak acidic conditions at room temperature, the unsaturated hydrocarbons in coking refined benzene can be removed, and the colorimetric effect of pickling can be reduced. and bromine price indicators.

Embodiment 3

[0034] The sample and basic processing steps are the same as in Example 1. Take 40ml of coking refined benzene and mix with 100ml of 0.403mol / l potassium permanganate aqueous solution. After mixing, the pH value of the solution is about 7. Stir at 50°C for 1 hour, and let it stand for stratification Finally, the benzene in the upper layer is taken out, washed with 30% NaOH solution, and the quality indicators of the coked refined benzene obtained are as follows: acid wash colorimetric 0.2g / l, bromine value 0.042g / 100ml, total sulfur 47.9mg / kg, thiophene in the total sulfur 36.4 mg / kg.

[0035] Coking refined benzene is mixed with 0.403mol / l potassium permanganate aqueous solution, the mixing volume ratio is 1:2.5, stirred once under neutral conditions of 50°C, the unsaturated hydrocarbons in coking refined benzene can be removed, and at the same time, part of the Coke thiophene in refined benzene, reduce pickling colorimetry, bromine value and total sulfur content indicators. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com