Process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil

A technology of raffinate oil and solvent oil, which is applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment. It can solve the problem of rising dry point of n-hexane, reduce device energy consumption, reduce product cost, and prolong catalyst life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

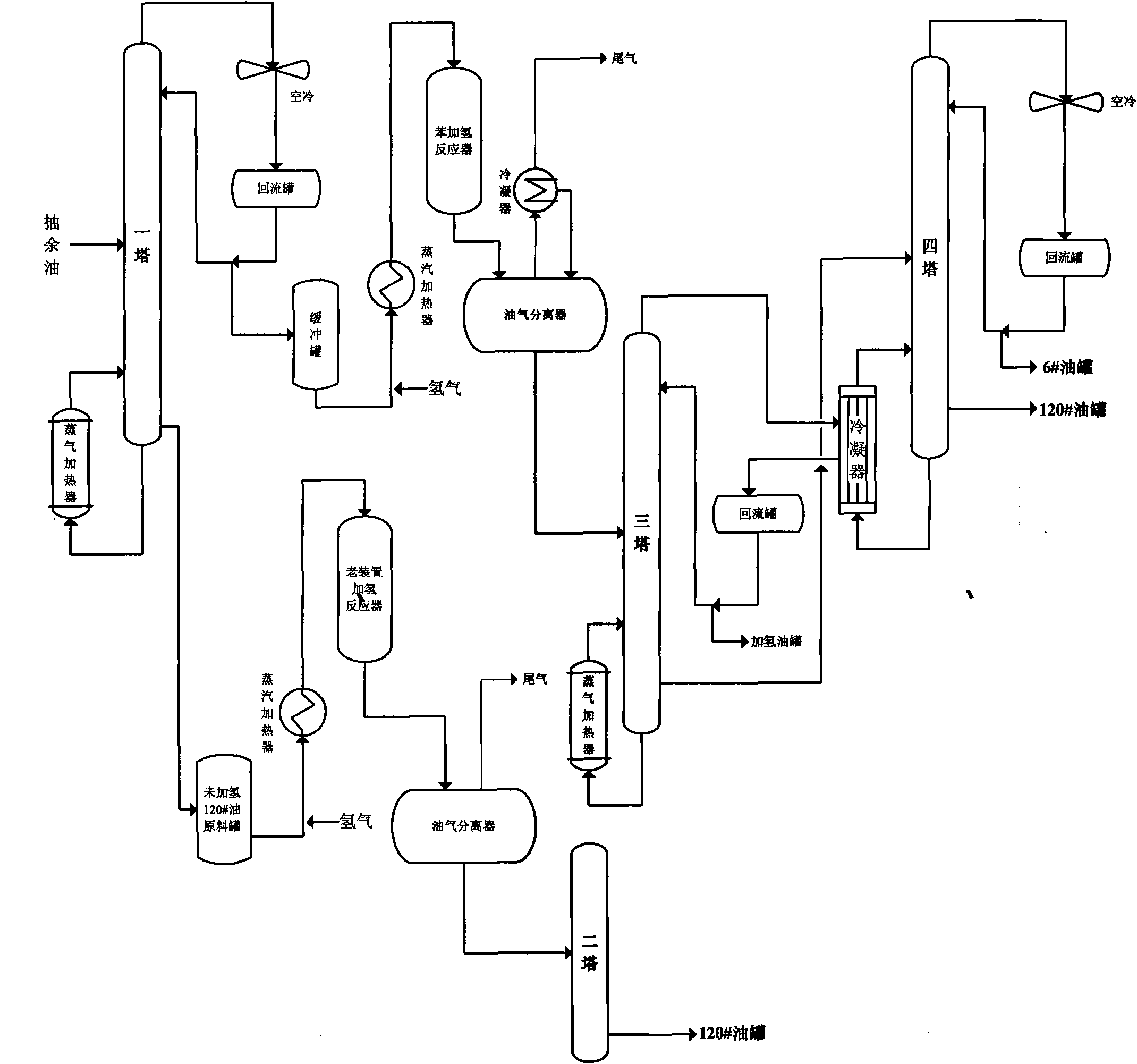

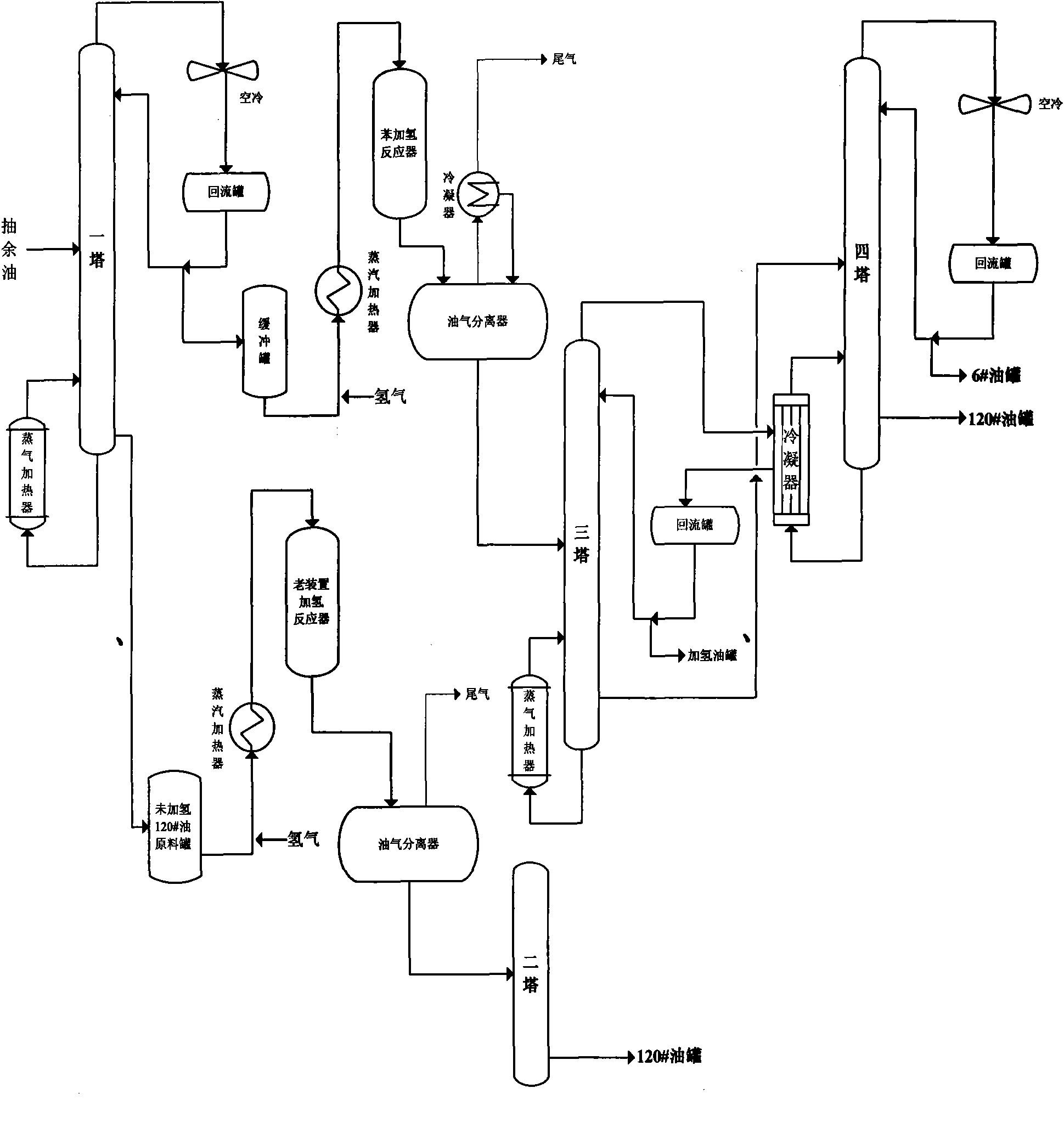

[0025] Such as figure 1 In the process of removing aromatics from raffinate oil to produce solvent oil, the raw material raffinate oil with high bromine value enters a tower (a tower: feed: 10.8 tons / hour; tower top temperature: 80.4°C; pressure: 0.03MPa; Tower bottom temperature: 121.9°C; reflux ratio: 0.8-1.0; number of trays: 48 layers + 6 meters of packing; separation conditions: the fraction with a dry point ≤ 90°C is cut from the top of the tower, and the fraction with a dry point of 90°C to 120°C is cut from the side line. The bottom of the tower is the heavy fraction > 120°C), and catalyst poisons such as sulfolane, part of water, and colloid in the raffinate are discharged from the bottom of the tower. The light com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com