Catalyst for C9 petroleum resin hydrogenation reaction and preparation method thereof

A technology of hydrogenation reaction and petroleum resin, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Reduce catalyst activity and other problems, achieve the effect of improving sintering resistance, high catalytic activity, and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

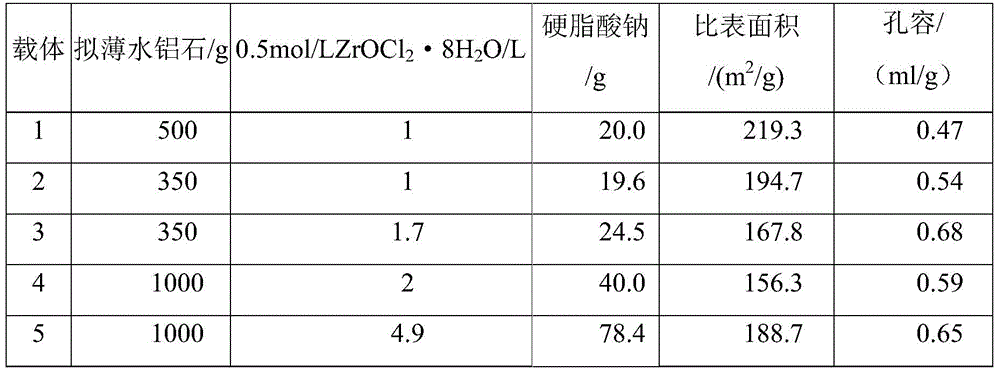

[0025] Preparation of catalyst support

[0026] Weigh 500g of pseudo-boehmite and stir vigorously with 2L of deionized water, then add 0.5mol / L of ZrOCl in 1L volume 2 ·8H 2 O aqueous solution is dripped in the above-mentioned solution with the speed of 5ml / min, then adds 20g pore-enlarging agent sodium stearate in the solution, after the solution mixes and becomes homogeneous system, slowly adds ammoniacal liquor, until the pH value reaches 7-8, The mixture was aged at room temperature for 4 hours and then sonicated for 20 minutes. The resulting solid was washed with deionized water until AgNO 3 The solution detects that there is no Cl in the filtrate -1 ions, and then washed three times with ethanol, then dried the solid at 120°C for 12h, and calcined at 550°C for 4h in an air atmosphere to obtain a composite zirconia-alumina carrier.

[0027] Carriers 2, 3, 4, and 5 were prepared according to the above-mentioned preparation methods with different raw powder ratios. The ...

Embodiment 2

[0031] Loading of active ingredients

[0032] Take by weighing 100g (100ml) of 1-5 carrier among the embodiment 1 respectively, add the Ni(NO of 50ml (0.16gNi / ml) 3 ) 2 Nickel nitrate aqueous solution and 50ml (0.006gPt / ml) tetraammine platinum nitrate (Pt(NH 3 ) 4 (NO 3 ) 2 ) solutions were mixed evenly, put into a vacuum drying oven at room temperature for vacuum impregnation for 12 hours, dried at 120°C, and roasted at 500°C for 4 hours to obtain the corresponding catalysts A-1, A-2, A-3, A-4, and A-5 .

Embodiment 3

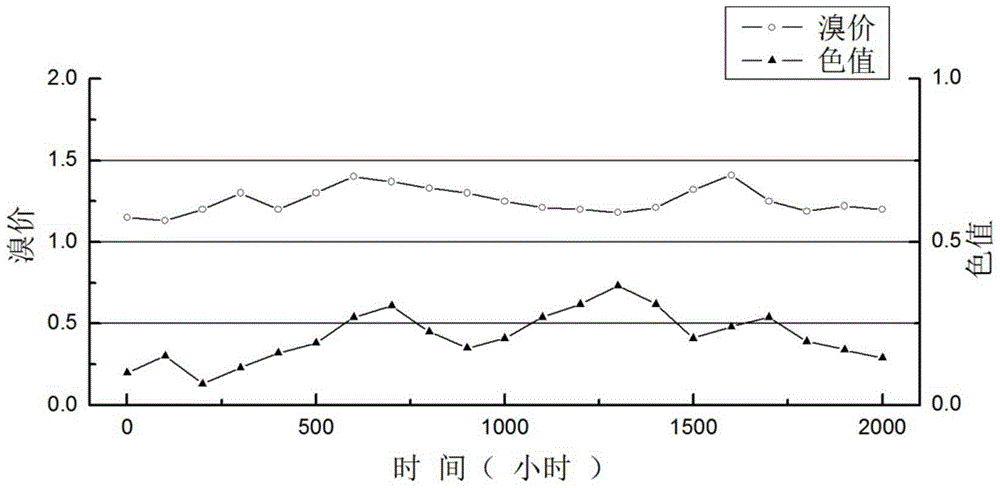

[0034] Catalyst activity evaluation

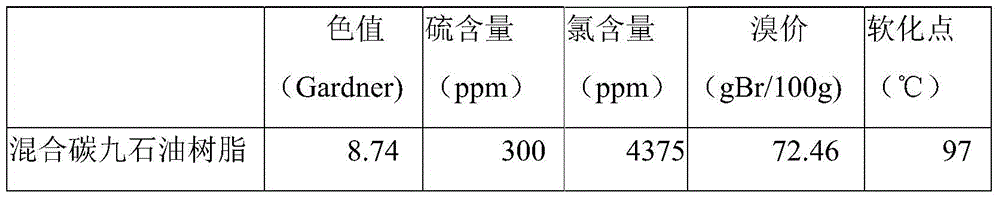

[0035] The mixed C9 petroleum resin is dissolved in a cyclohexane solvent to form a raw material solution with a concentration of 10% (wt), wherein the sulfur content is 300ppm, and the chlorine content is 4375ppm.

[0036] The physical properties of raw material mixed C9 petroleum resin are as follows:

[0037] Table 2 Raw resin physical properties

[0038]

[0039] The catalyst prepared in Example 2 was loaded into a fixed-bed reaction tube, and reduced at 400° C. for 3 hours in a hydrogen atmosphere under normal pressure to activate the catalyst and carry out hydrogenation reaction. Reaction conditions: pressure 8.0Mpa, bed temperature 200°C, liquid space velocity 1.0h -1 , the hydrogen-to-liquid ratio is 400:1, the reaction mixture is washed with alkali and washed with water, and the hydrogenated mixed product is removed by the falling film evaporator to remove the solvent and its byproducts, and the falling film evaporator remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com