Cerium-based carbon-containing nanotube composite RE oxide and its prepn

A composite oxide and rare earth compounding technology, which is applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve problems such as poor thermal stability, reduced oxygen storage capacity, and easy sintering, and achieve good thermal stability, Good anti-sintering performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

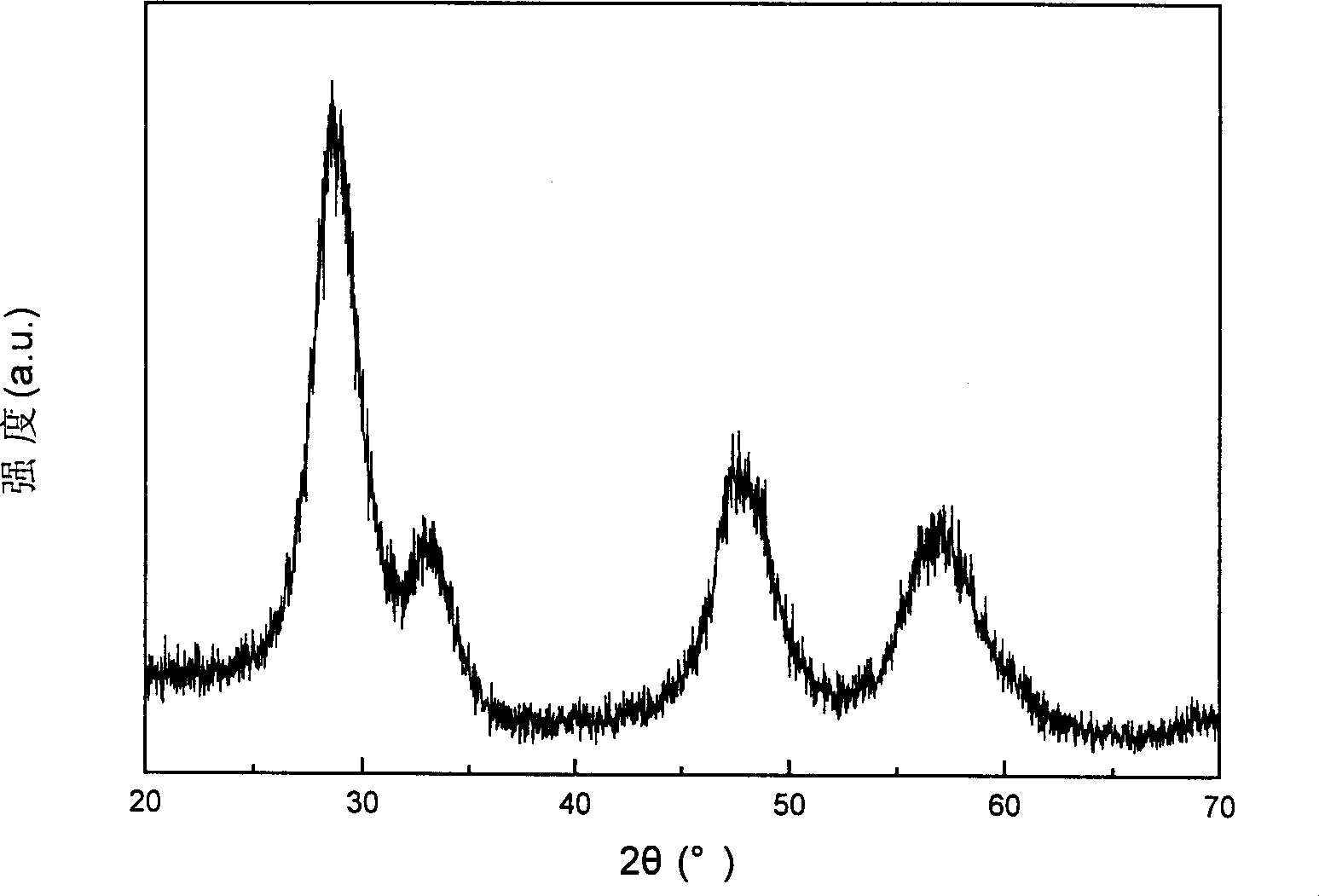

Embodiment 1

[0024] In order to prepare 100g of composite oxides, the weights of ceria, zirconia, lanthanum oxide, praseodymium oxide and carbon nanotubes are respectively 59.5g, 30g, 4g, 6g and 0.5g. At first getting concentration is 0.3M cerium nitrate 1153ml, 0.5M zirconium nitrate 488ml, 0.5M lanthanum nitrate 49.1ml and 0.5M praseodymium nitrate 70.5ml solution, is prepared into mixed solution; Take ammonium carbonate solution as precipitation agent (the molar weight of precipitation agent is 1.1 times of precipitating agent needed for all precipitation cations), under the condition of stirring, add the carbon nanotube of 0.5g in 2M, 602ml ammonium carbonate solution, and add 17.6ml (accounting for the volume 1vol% of mixed nitric acid solution) weight hundred Divide the sodium dodecylsulfonate aqueous solution with a concentration of 5%, and stir for 30 minutes; then add the above-mentioned mixed nitric acid solution to the ammonium carbonate solution, the pH value is controlled at 8....

Embodiment 2

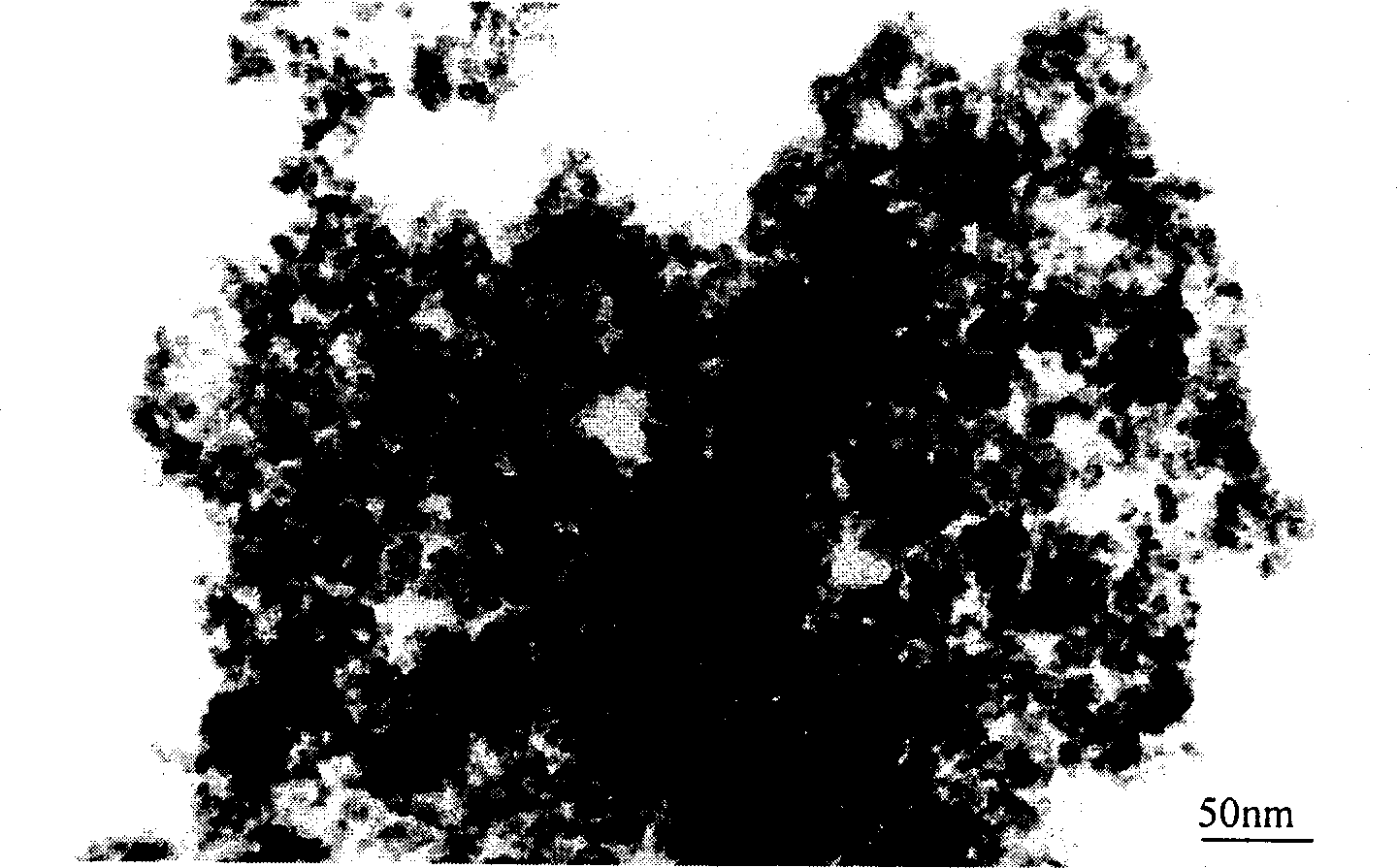

[0027]In order to prepare 100g of composite oxide, the weights of ceria, zirconia, lanthanum oxide, praseodymium oxide and carbon nanotubes are 50g, 39.95g, 4g, 6g and 0.05g respectively. First get concentration and be that 0.5M cerium nitrate 581.4ml, 0.3M zirconium nitrate 1083ml, 0.5M lanthanum nitrate 49.1ml and 0.5M praseodymium nitrate 70.5ml solution are prepared into mixed nitric acid solution; The amount is 1.1 times of the precipitating agent required for all precipitation cations), under the condition of stirring, add the carbon nanotube of 0.05g in the 0.5M, 2586ml ammonium oxalate solution, and add 89.2ml (accounting for the volume 5vol% of mixed nitric acid solution) The Tween 60 aqueous solution with a concentration of 1% by weight was stirred for 30 minutes, then the mixed nitric acid solution was added to the above-mentioned ammonium oxalate solution, the pH value was controlled at 7.5, and the reaction time was 80 minutes to generate a precipitate; filter the ...

Embodiment 3

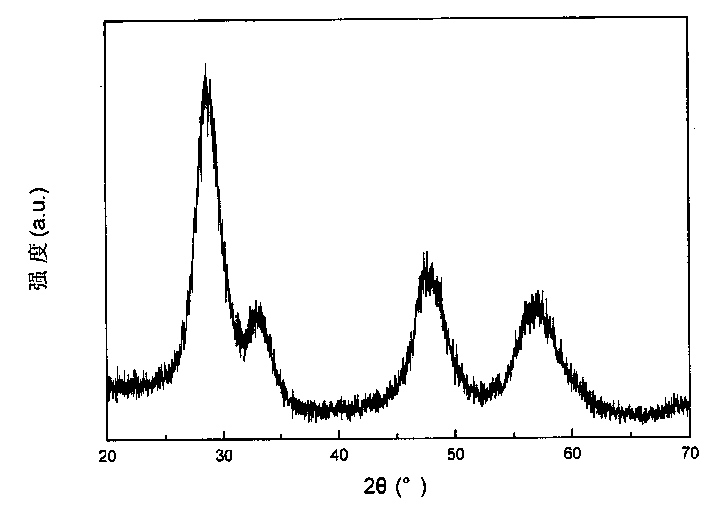

[0030] Prepare 100 g of composite oxides, in which the weights of cerium oxide, zirconia, lanthanum oxide, praseodymium oxide, and carbon nanotubes are 69.7 g, 20 g, 4 g, 6 g, and 0.3 g, respectively. First, take 1351ml of 0.3M cerium nitrate, 325ml of 0.5M zirconium nitrate, 49.1ml of 0.5M lanthanum nitrate and 70.5ml of 0.5M praseodymium nitrate to make mixed solutions; (the molar weight of precipitating agent is 1.1 times of precipitating agent required for all precipitating cations) in, add the carbon nanotube of 0.3g, and add 18ml (accounting for the volume 1% of mixed nitric acid solution) concentration by weight is 5% sixteen Alkyl ammonium chloride alcohol solution, stirred for 30 minutes; then the mixed nitric acid solution was added to the above ammonium carbonate solution, the pH value was controlled at 10, the reaction time was 60 minutes, and a precipitate was formed; the precipitate was filtered, and then at 600 ° C Calcined for 1 hour. Calcined at 650°C for 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com