Cerium oxide-coated precious metal nano-catalyst and preparation method thereof

A nano-catalyst and noble metal technology, applied in the field of noble metal catalyst preparation, can solve the problems of poor thermal stability and anti-poisoning ability, achieve excellent anti-sintering performance, reduce costs, and simplify the preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a catalyst PdCeO coated with palladium in cerium oxide 2 , which is prepared by the following steps:

[0039] Dissolve 0.15g sodium bromide in 100mL water, add 0.6g cerium nitrate, stir and mix well, then add 0.25mmol Na 2 PdCl 4 , to obtain a mixed solution;

[0040] The temperature of the mixed solution was raised and stabilized at 60 ° C, and 0.25 mL of ammonia water (concentration: 25 wt %) was added, kept for 1 h and then cooled to room temperature;

[0041] Add 400mL of acetone and carry out centrifugation, then wash the separated product three times to obtain the catalyst PdCeO coated with cerium oxide palladium 2 , which contains palladium 11wt.%, cerium oxide 89wt.%.

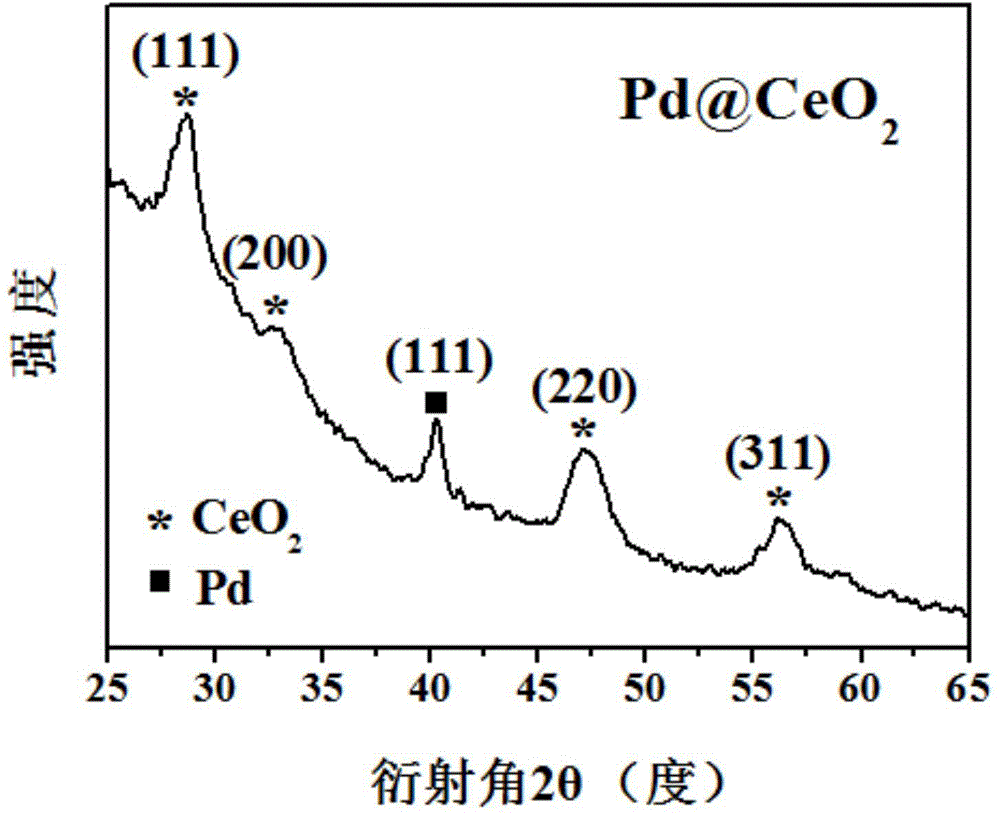

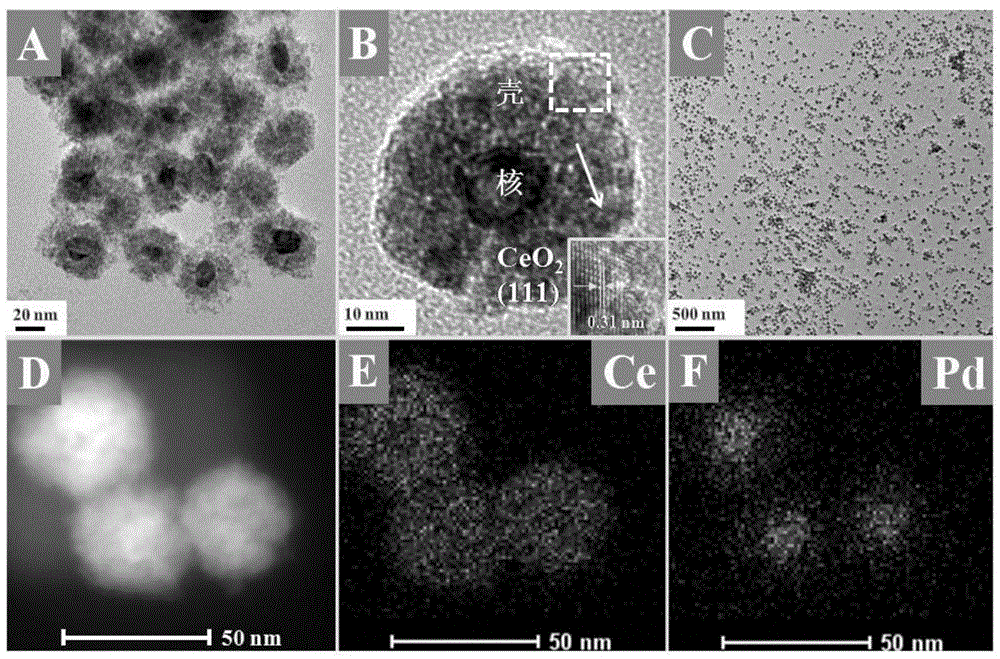

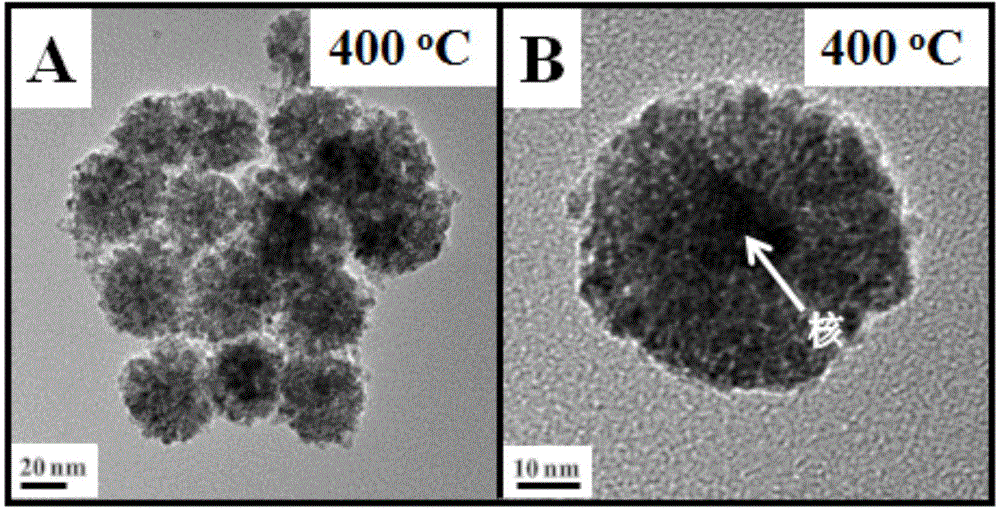

[0042] figure 1 for PdCeO 2 The XRD pattern of figure 1 It can be seen that the PdCeO 2 It is composed of pure cerium oxide and palladium. figure 2 for PdCeO 2 The TEM image of figure 2 It can be seen that the PdCeO 2With a core-shell structure, cerium oxide...

Embodiment 2

[0048] This embodiment provides a cerium oxide-coated gold catalyst AuCeO 2 , which is prepared by the following steps:

[0049] Dissolve 0.15g of sodium chloride in 100mL of water, add 0.6g of cerium nitrate, stir and mix evenly, then add 0.25mmol of chloroauric acid to obtain a mixed solution;

[0050] The temperature of the mixed solution was raised and stabilized at 60 °C, and 0.25 mL of ammonia water (concentration: 25 wt.%) was added, kept for 1 h and then cooled to room temperature;

[0051] Add 400mL of acetone and carry out centrifugation, then wash the separated product three times with water to obtain the catalyst AuCeO coated with cerium oxide. 2 .

[0052] Figure 5A and Figure 5B AuCeO prepared for this example 2 The TEM image of Figure 5A and Figure 5B It can be seen that the catalyst AuCeO 2 It maintains a good core-shell structure, which contains 14wt.% of gold and 86wt.% of cerium oxide. The obtained product is a core-shell structure of ceria-coat...

Embodiment 3

[0054] This embodiment provides a catalyst PtCeO coated with platinum in cerium oxide 2 , which is prepared by the following steps:

[0055] Dissolve 0.15g of potassium iodide in 100mL of water, add 0.6g of cerium nitrate, stir and mix evenly, then add 0.25mmol of chloroplatinic acid to obtain a mixed solution;

[0056] The temperature of the mixed solution was raised and stabilized at 60 °C, and 0.25 mL of ammonia water (concentration: 25 wt.%) was added, kept for 1 h and then cooled to room temperature;

[0057] Add 400mL acetone and carry out centrifugation, then wash the separated product three times with water to obtain the catalyst PtCeO coated with cerium oxide platinum. 2 , which contains 21wt.% of platinum and 79wt.% of cerium oxide, and the obtained product has a core-shell structure of cerium oxide covering platinum.

[0058] Figure 6 The PtCeO prepared for this example 2 The TEM image of Figure 6 In A to C and D to F, the consumption of potassium iodide is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com