Cobalt-based catalyst having core-shell structure, and preparation method thereof

A cobalt-based catalyst, core-shell structure technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. and other problems, to achieve the effect of high oil-wax selectivity, easy industrial scale-up, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

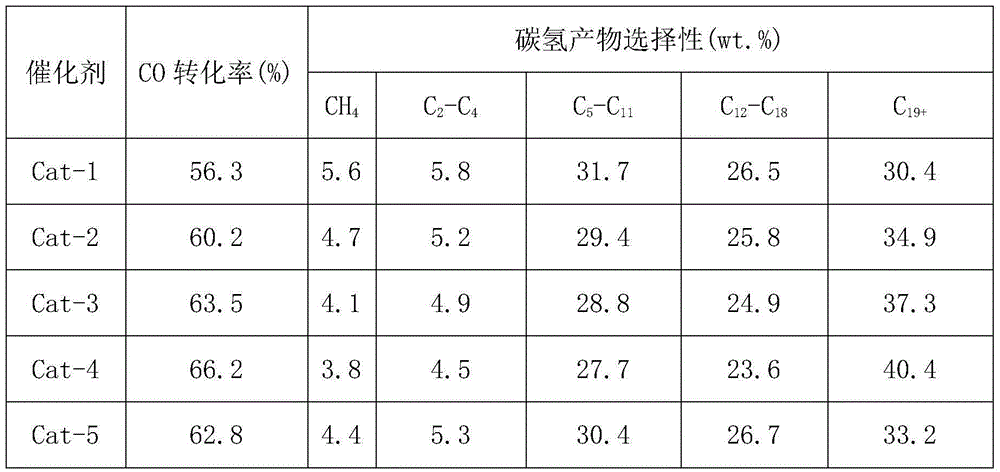

Examples

Embodiment 1

[0024] By mass percentage Co:MnO 2 :ZrO 2 / Al 2 o 3 Composite oxide carrier=10:1:89 ratio to synthesize cobalt-based catalyst. Specific steps are as follows:

[0025] Step 1, according to the above-mentioned mass percentage of 10:1:89, first weigh out 5g microspherical ZrO 2 / Al 2 o 3 Composite oxide carrier (prepared by spray drying molding technology, particle size is 500μm, specific surface area is 230m 2 / g, the pore volume is 1.1cm 3 / g, the average pore size distribution is 15nm).

[0026] Step 2, take by weighing 2.77g cobalt nitrate and 0.16g manganese nitrate, be dissolved in 5mL alcoholic water (V 乙醇 :V 水 =1:1), it is prepared as an impregnating solution.

[0027] Step 3, 5g microspherical ZrO 2 / Al 2 o 3 The composite oxide carrier was placed in a rotary evaporator, and under the condition of rapid stirring, every 1g of ZrO 2 / Al 2 o 3 At a drop rate of 1mL / s for the composite oxide carrier, the impregnation solution prepared in step 2 was quickly p...

Embodiment 2

[0029] By mass percentage Co:La 2 o 3 :SiO2 2 / Al 2 o 3 Composite oxide carrier=15:0.5:84.5 ratio to synthesize cobalt-based catalyst. Specific steps are as follows:

[0030] Step 1, according to the above mass percentage of 15:0.5:84.5, first weigh out 5g of clover-type SiO 2 / Al 2 o 3 Composite oxide carrier (prepared by extrusion molding technology, the particle size length is in the range of 10mm, the diameter is 5mm, and the specific surface area is 260m 2 / g, the pore volume is 1.0cm 3 / g, the average pore size distribution is 14nm).

[0031] Step 2, weigh 4.38g cobalt nitrate and 0.08g lanthanum nitrate, dissolve in 5mL alcohol water (V 乙醇 :V 水 =2:1), prepared as impregnation solution.

[0032] Step 3, 5g clover-type SiO 2 / Al 2 o 3 The composite oxide carrier was put into a rotary evaporator, and under the condition of rapid stirring, every 1g SiO 2 / Al 2 o 3 At a dropping rate of 1.5mL / s for the composite oxide carrier, the impregnation solution prep...

Embodiment 3

[0034] By mass percentage Co:NiO:TiO 2 / Al 2 o 3 Composite oxide carrier=20:0.5:79.5 ratio to synthesize cobalt-based catalyst. Specific steps are as follows:

[0035] Step 1, according to the above mass percentage of 20:0.5:79.5, first weigh out 5g cylindrical TiO 2 / Al 2 o 3 Composite oxide carrier (prepared by extrusion molding technology, the particle size length is in the range of 8mm, the diameter is 4mm, and the specific surface area is 250m 2 / g, the pore volume is 0.9cm 3 / g, the average pore size distribution is 12nm).

[0036] Step 2, weigh 6.21g cobalt nitrate and 0.12g nickel nitrate, dissolve in 4.5mL alcohol water (V 乙醇 :V 水 =5:1), prepared as impregnation solution.

[0037] Step 3, 5g cylindrical TiO 2 / Al 2 o 3 The composite oxide carrier was placed in a rotary evaporator, and under rapid stirring conditions, every 1g TiO 2 / Al 2 o 3 At the drop rate of the composite oxide carrier 2mL / s, the impregnation solution prepared in step 2 was quickly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com