A processing method for inferior heavy oil and/or inferior residual oil

A processing method and technology for low-quality heavy oil, which is applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment. It can solve the problems of short operation period, excessive dry gas, and excessive coking, and achieve high yield of light oil, The effect of extending the operating cycle and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

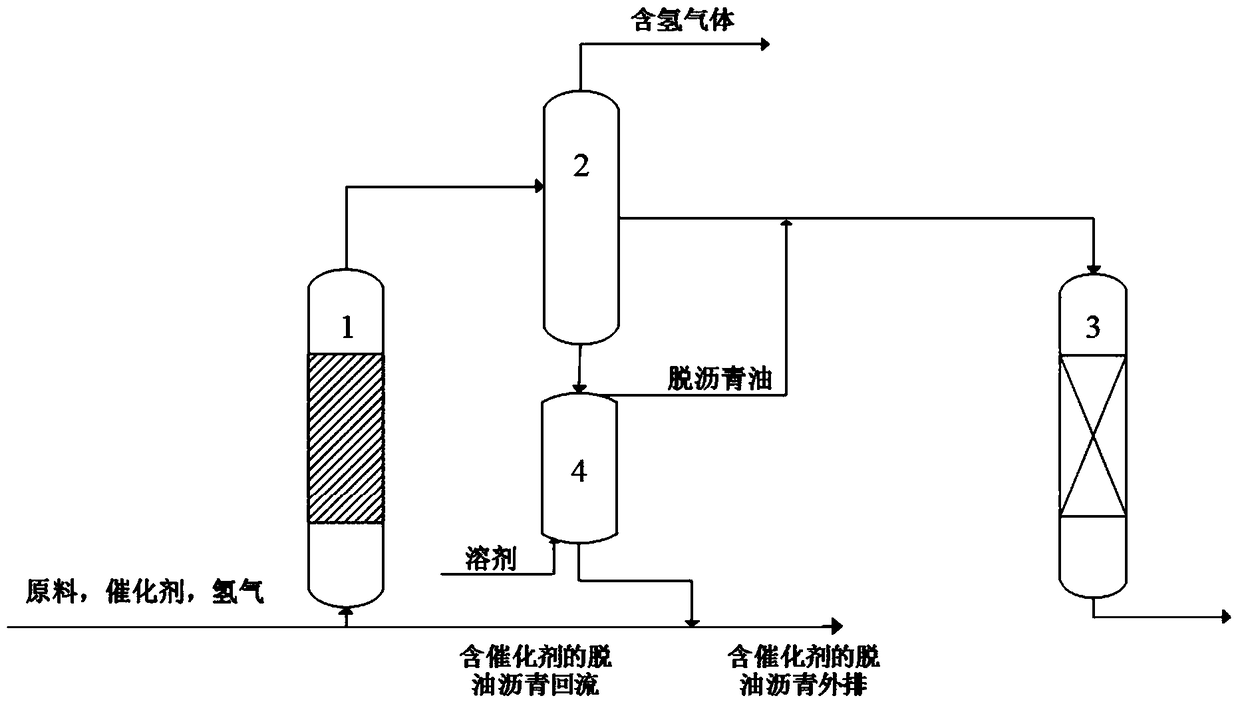

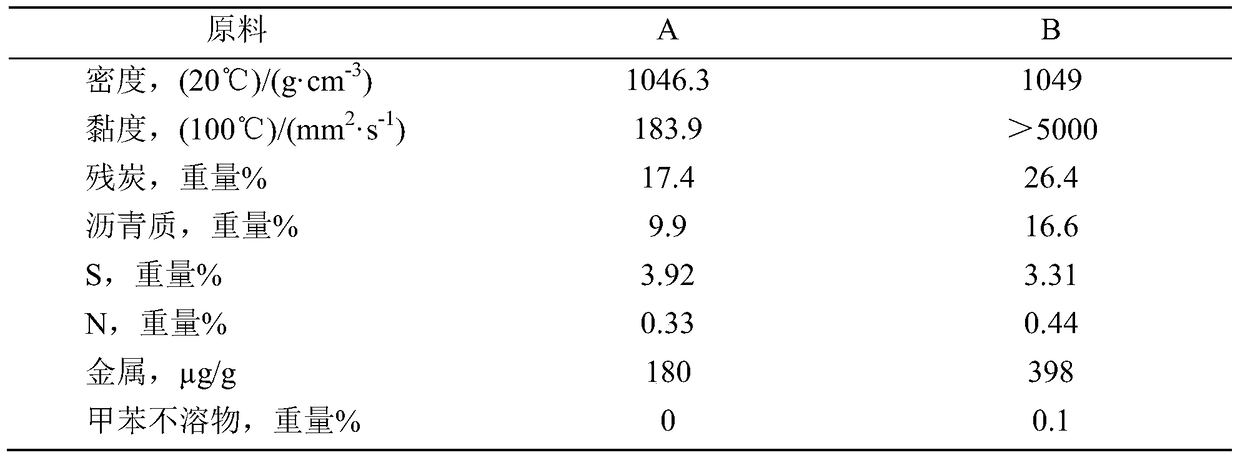

[0071] With A as raw material (properties see Table 1), in the slurry bed reactor with C as catalyst (properties see Table 2), material flow chart as figure 1 shown.

[0072] Grind the catalyst and control the particle size to 100-150 mesh by sieving method, and feed it into the slurry bed reactor 1 from bottom to top along with the raw material and hydrogen at 3.0% by weight of the weight of the fresh raw material oil. The operating conditions for controlling the slurry bed reactor 1 are: temperature 420°C, pressure 10MPa, hydrogen-oil volume ratio 1000, space velocity 0.2h -1 . The conversion depth of the material at the outlet of slurry bed reactor 1 is shown in Table 3. The material enters the high-pressure separator 2 from the slurry bed reactor 1. The operating conditions of the high-pressure separator 2 include a temperature of 380°C and a pressure of 10MPa, and the discharge speed of the high-pressure separator is controlled so that the heavy matter obtained from the...

Embodiment 2

[0077] Taking B as raw material (see Table 1 for properties), and taking D as catalyst (see Table 2 for properties) in the slurry bed reactor, the material flow chart is as follows figure 1 shown.

[0078] Grind the catalyst and control the particle size to 120-180 mesh by sieving method, and feed it into the slurry bed reactor 1 from bottom to top along with the raw material and hydrogen at 5.0% by weight of the weight of the fresh raw material oil. The operating conditions for controlling the slurry bed reactor 1 are: temperature 380°C, pressure 12MPa, hydrogen-oil volume ratio 1500, space velocity 0.1h -1 . The conversion depth of the material at the outlet of slurry bed reactor 1 is shown in Table 3. The material enters the high-pressure separator 2 from the slurry bed reactor 1. The operating conditions of the high-pressure separator 2 include a temperature of 390°C and a pressure of 9MPa, and the discharge speed of the high-pressure separator is controlled so that the ...

Embodiment 3

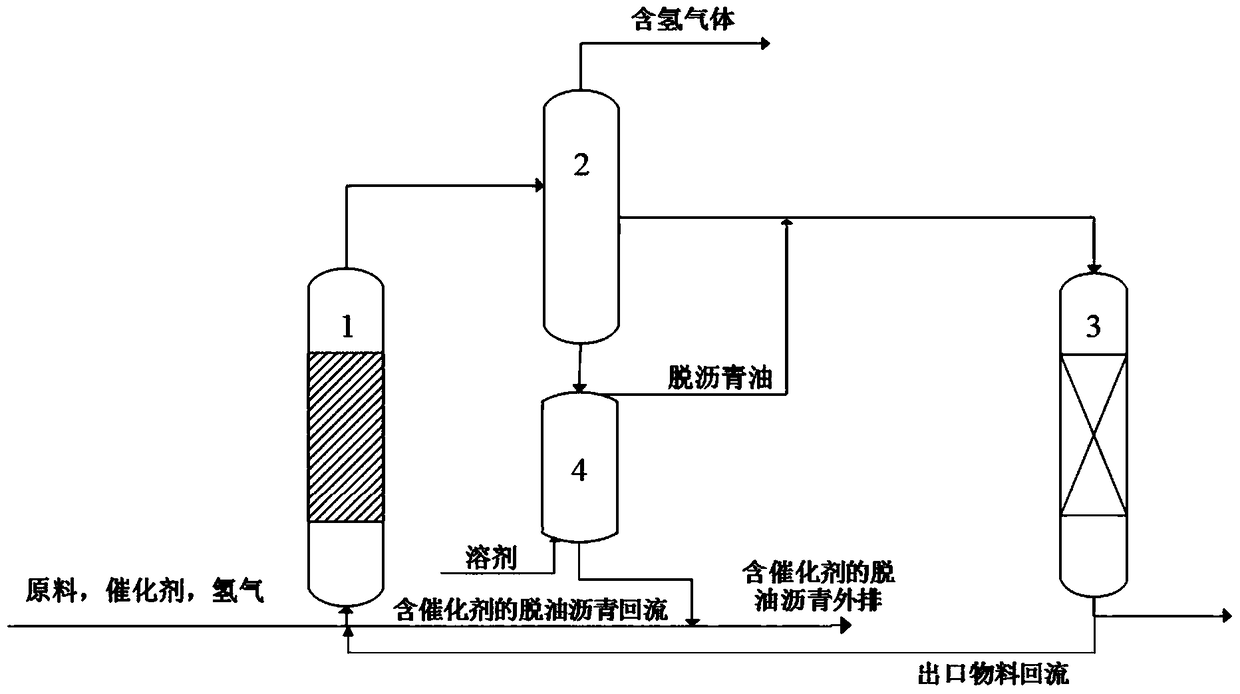

[0089] With A as raw material (properties see Table 1), in the slurry bed reactor with C as catalyst (properties see Table 2), material flow chart as figure 2 shown.

[0090] Grind the catalyst and control the particle size to 200-240 mesh by sieving method, and feed it into the slurry bed reactor 1 from bottom to top along with the raw material and hydrogen at 6.0% by weight of the weight of the fresh raw material oil. Control the operating conditions of slurry bed reactor 1 as follows: temperature 400°C, pressure 10MPa, hydrogen-oil volume ratio 1000, space velocity 0.2h -1 . The conversion depth of the material at the outlet of slurry bed reactor 1 is shown in Table 3. The material enters the high-pressure separator 2 from the slurry bed reactor 1. The operating conditions of the high-pressure separator 2 include a temperature of 380°C and a pressure of 10MPa, and the discharge speed of the high-pressure separator is controlled so that the heavy matter obtained from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com