Heavy raw oil treatment apparatus, its application, and heavy raw oil treatment method

A treatment device and treatment method technology, which is applied in the treatment of hydrocarbon oil, hydroprocessing process, petroleum industry, etc., can solve the problems of wasting reactor space, etc., and achieve the effects of improved space utilization, fewer high-pressure valves, and reliable operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

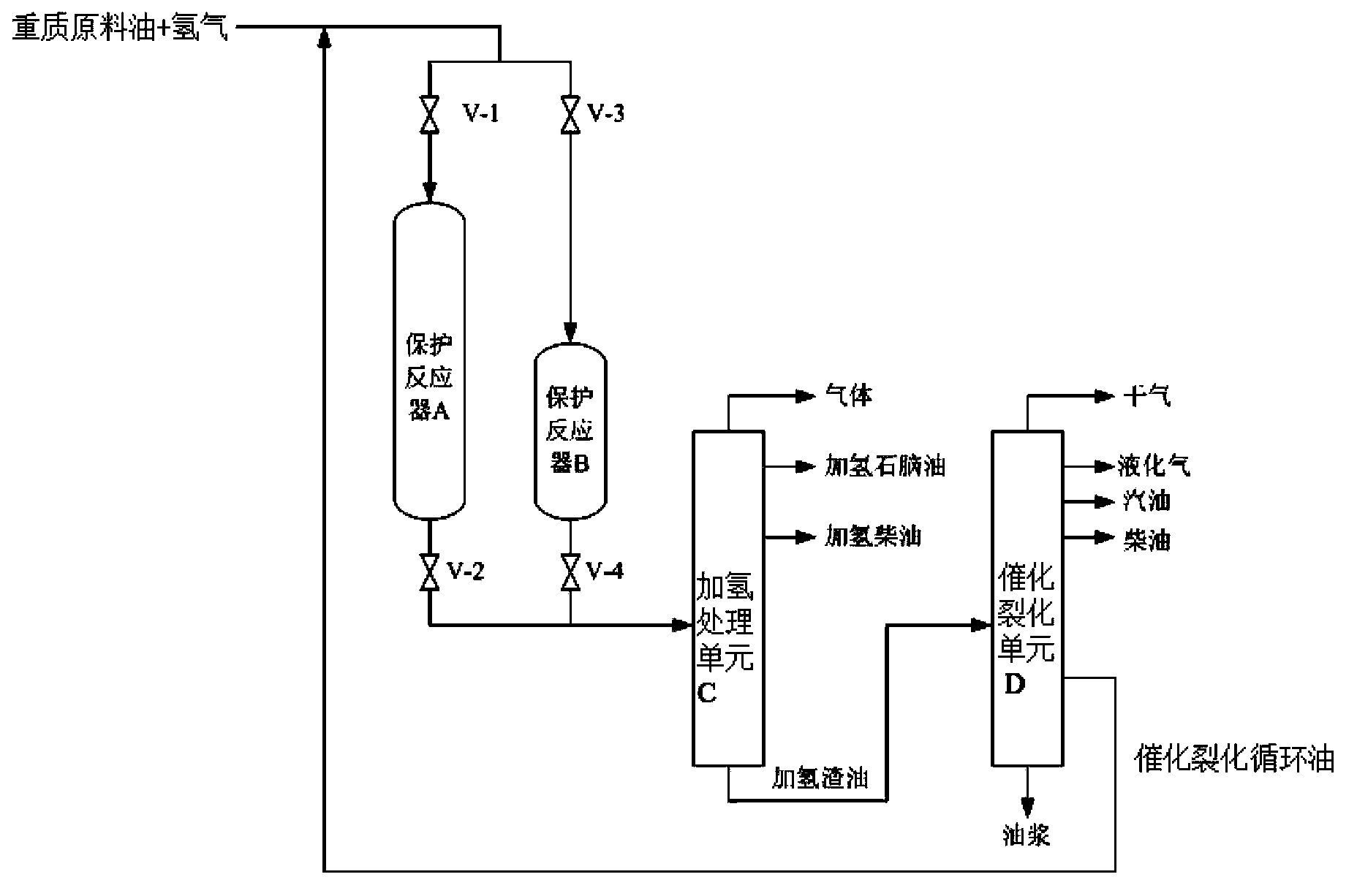

[0057] In the heavy crude oil treatment device used in this example, the main hydrogenation protection reactor is a protection reactor A, the standby hydrogenation protection reactor is a protection reactor B, and the hydroprocessing unit C is a fixed bed slag Oil hydrogenation unit, the catalytic cracking unit D is a laboratory fixed fluidized bed catalytic cracking unit, such as figure 1 shown.

[0058] The protection reactor A is filled with 30mL of RG-20 catalyst, 30mL of RG-30E catalyst, 30mL of RG-30A catalyst and 30mL of RG-30B catalyst, totaling 120mL; the protection reactor B is filled with 10mL of RG-20 catalyst and RG-30E Catalyst 10mL, RG-30A catalyst 10mL and RG-30B catalyst 10mL, 40mL in total; fixed-bed residual oil hydrogenation unit reactor filled with RDM-32 catalyst 200mL, RDM-33 catalyst 200mL, RMS-30 catalyst 200mL and RCS- 30 Catalyst 300mL, total 900mL.

[0059] The trade name of the catalytic cracking catalyst is MLC-500, which is produced by Sinopec ...

Embodiment 2

[0079] The test device of embodiment 2 is the same as that of embodiment 1, and the catalyst type and loading amount of protection reactor A and protection reactor B are the same as that of embodiment 1; The catalyst type and loading amount of the fixed fluidized catalytic cracking unit are the same as those in Example 1.

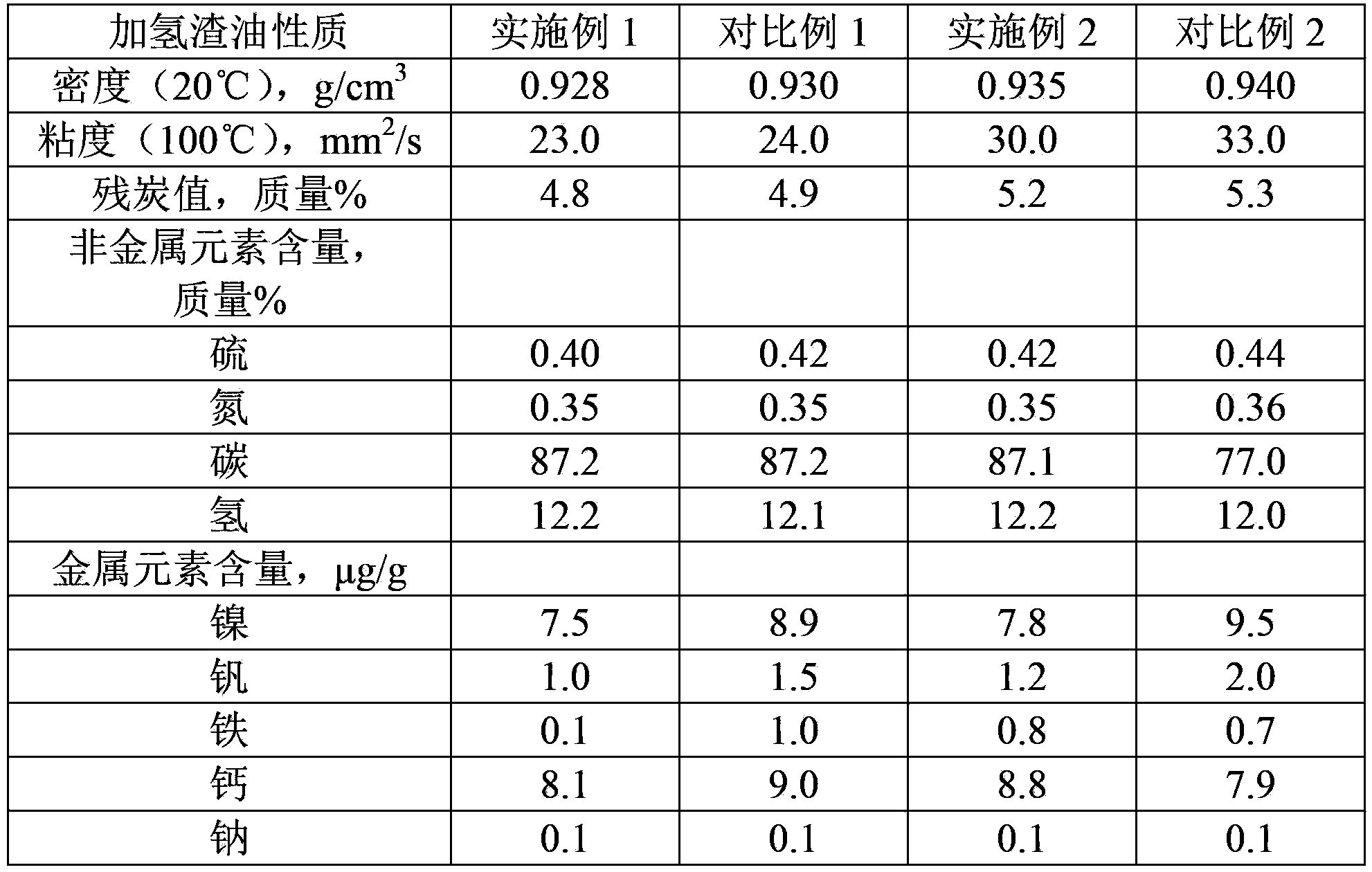

[0080] The raw material oil is atmospheric residue AR, and its properties are shown in Table 1. After AR is mixed with hydrogen, it enters the protection reactor A, and then enters the reactor of the fixed-bed residual oil hydrogenation unit for hydrogenation treatment. The operating conditions are the same as in Example 1, and the properties of the obtained hydrogenated residue are shown in Table 2.

[0081] After entering the residual oil for 1800 hours, the pressure drop of the protective reactor A is close to 0.6MPa, and then the upstream and downstream valves V-3 and V-4 of the reactor B are opened, and at the same time, the upstream and downstream va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com