Aluminum-silicon-strontium-titanium-boron alloy welding wire and intelligent preparation method thereof

A technology of alloy welding wire and aluminum-silicon-strontium, which is applied in the field of aluminum alloy welding wire, can solve the problems of high error rate in manual handling, high safety hazards, and long allocation cycle, so as to improve the mechanical properties of the alloy and the strength of the weld seam, and refine the weld seam Organization of crystal grains and improvement of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

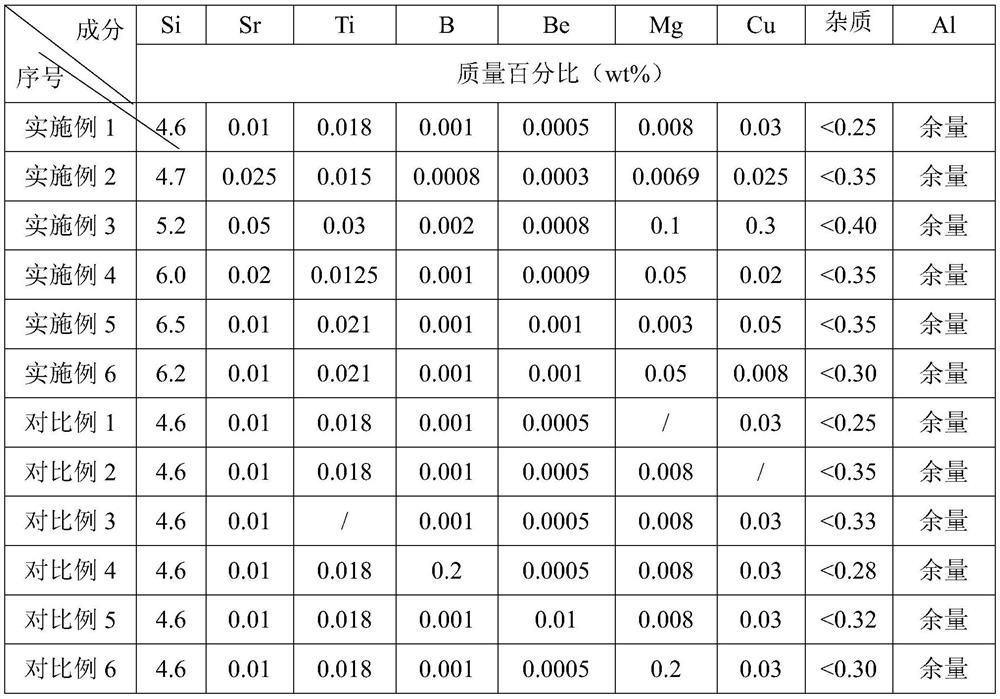

[0063] The aluminum-silicon-strontium-titanium-boron alloy welding wire of this embodiment has the following mass percentage components:

[0064] Silicon: 4.6wt%; Strontium: 0.01wt%; Titanium: 0.018wt%; Boron: 0.001wt%; Beryllium: 0.0005wt%; Magnesium: 0.008wt%; impurity elements.

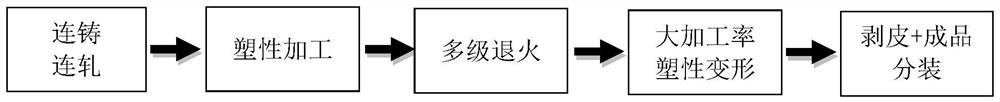

[0065] The aluminum-silicon-strontium-titanium-boron alloy welding wire of this embodiment is prepared through the following steps:

[0066]S1. Automatic material storage and automatic batching; (1) Raw material storage: Manually press the button of the conveying line to call for an empty pallet; put the materials to be stored on the master pallet at the storage entrance; manually select the material information (material information) on the PDA terminal Information includes material number, product form, supplier, etc.), and scan the parent pallet number, click "Confirm Storage" to complete the binding of the storage group tray; manually press the button of the conveyor line, and the conveyor lin...

Embodiment 2-3

[0076] The composition and content of the Al-Si-Sr-Ti-B alloy welding wire of Examples 2-3 are shown in Table 1 respectively, and the preparation method of the Al-Si-Sr-Ti-B alloy welding wire of Examples 2-3 is the same as that of Example 1.

Embodiment 4

[0078] The aluminum-silicon-strontium-titanium-boron alloy welding wire of this embodiment has the following mass percentage components:

[0079] Silicon: 6.0wt%; Strontium: 0.02wt%; Titanium: 0.0125wt%; Boron: 0.001wt%; Beryllium: 0.0009wt%; Magnesium: 0.05wt%; impurity elements.

[0080] The aluminum-silicon-strontium-titanium-boron alloy welding wire of this embodiment is prepared through the following steps:

[0081] S1. Automatic material storage and automatic batching; (1) Raw material storage: Manually press the button of the conveying line to call for an empty pallet; put the materials to be stored on the master pallet at the storage entrance; manually select the material information (material information) on the PDA terminal Information includes material number, product form, supplier, etc.), and scan the parent pallet number, click "Confirm Storage" to complete the binding of the storage group tray; manually press the button of the conveyor line, and the conveyor li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com