Container for an automatic injector

a technology for automatic injectors and containers, which is applied in the direction of containers, mechanical equipment, transportation and packaging, etc., can solve the problems of automatic injectors being inadvertently activated, injectors being likely to be exposed to various physical and environmental stresses, and the therapeutic agent stored inside the injectors to degrad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

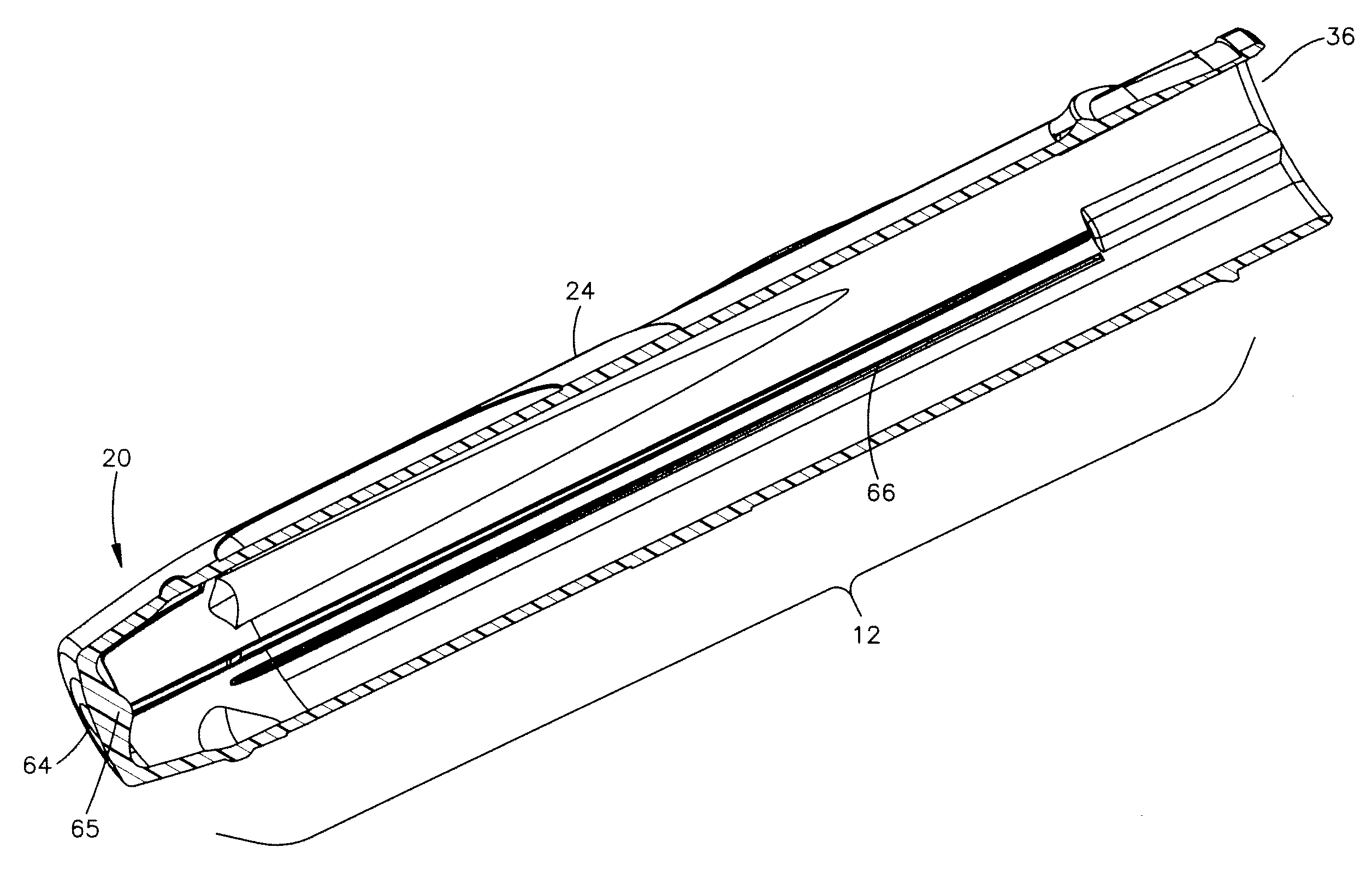

[0029]Automatic injector containers of the invention can store many types of automatic injectors, such as, for example, the EPIPEN® automatic injectors by Meridian Medical Technologies. Inc. Typical automatic injectors have a housing that contains a cartridge. The cartridge has one or more chambers containing a therapeutic agent. The housing has a needle end that usually contains a needle assembly attached to a chamber. The housing also has an activation end opposite the needle end that usually contains an activation assembly. The activation assembly includes a stored energy source such as a compressed spring. Activation of the activation assembly typically causes a sequence of internal movements within the housing that forces the needle into a user and the therapeutic agent through the needle.

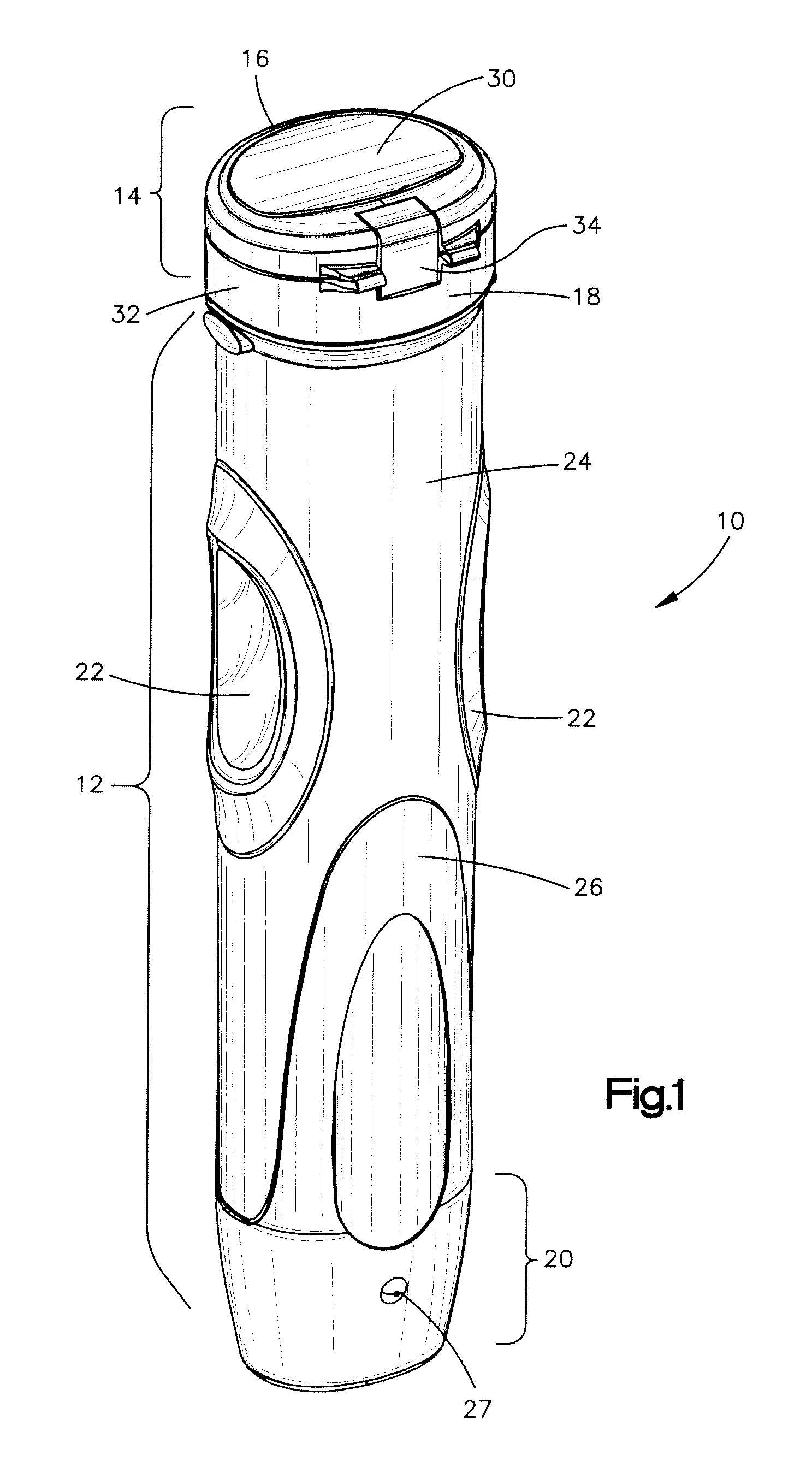

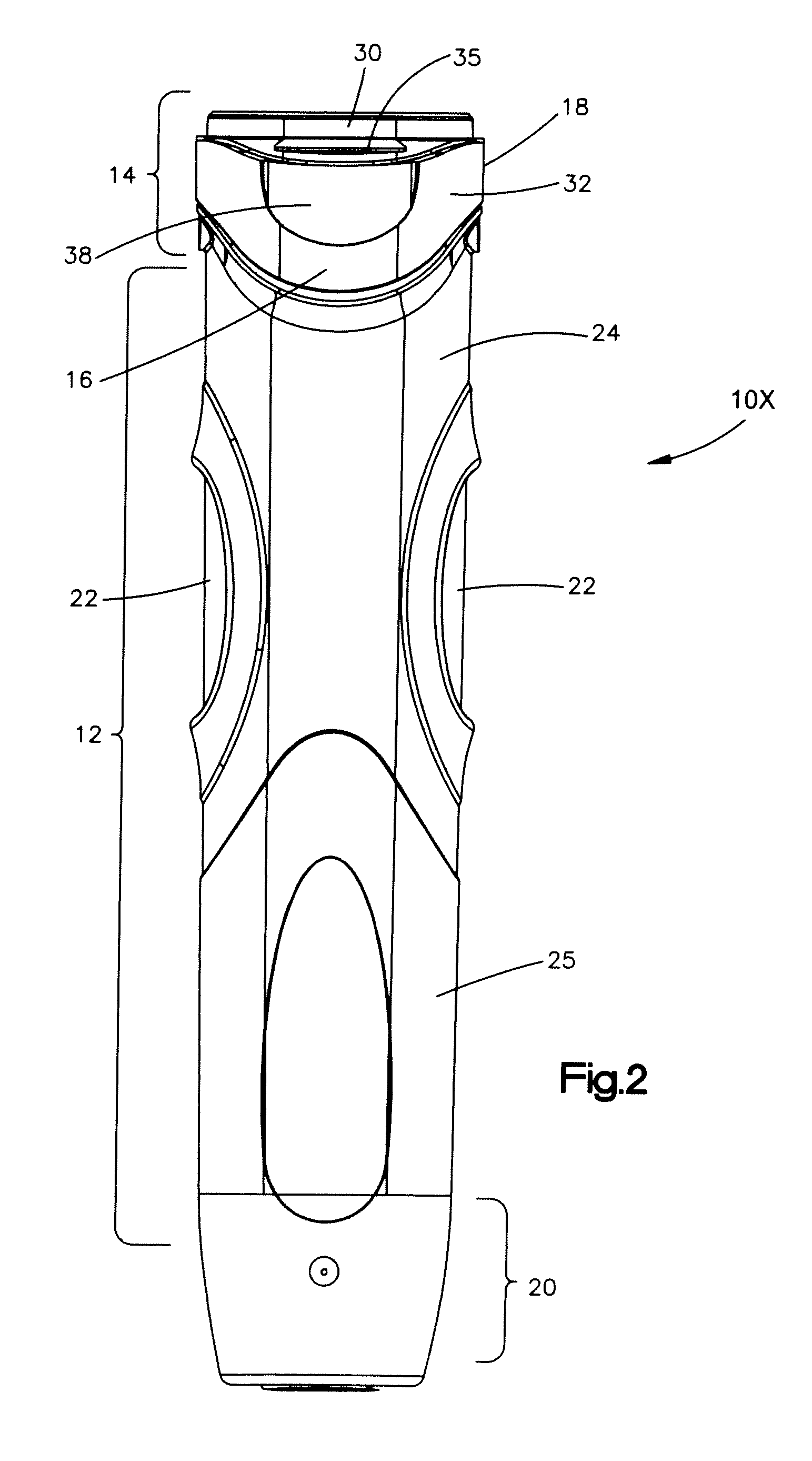

[0030]FIG. 1 shows an embodiment of an automatic injector container according to the invention. Container 10 includes a preferably cylindrically-shaped, enclosed body 12 and a cap 14. Body 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com