Box for packing glass plate and packing and unpacking method

A packaging method and glass plate technology, applied in packaging, transportation and packaging, packaging of fragile items, etc., can solve the problems of small number of glass plates stacked, large-scale equipment, and limitation of the number of pieces that can be stored and transported at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

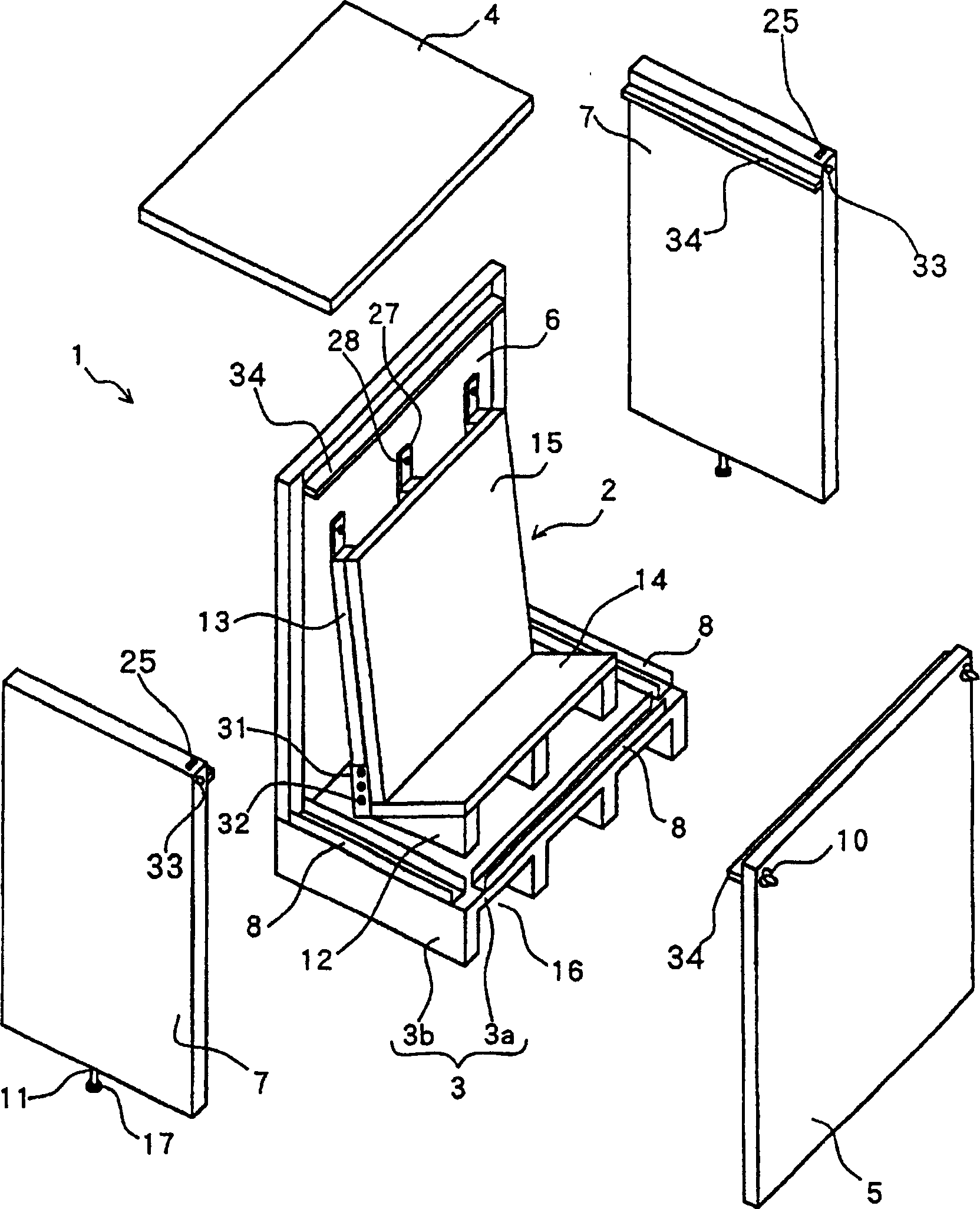

[0066] figure 1 It is a three-dimensional exploded view of a preferred glass plate packing box of the present invention.

[0067] The glass plate packaging box 1 of the present invention comprises: a pedestal 2 for placing glass plates; a bottom plate 3 for placing the pedestal 2; a front plate 5, a rear plate 6 and two side plates 7 erected on the bottom plate 3; Live the upper top plate 4. On the upper front edge and both side edges of the bottom plate 3, there are U-shaped members 8 opening upward for fitting the front plate 5 and the two side plates 7 therein. The U-shaped member 8 may be a structure in which a U-shaped groove is provided on the bottom plate 3, and the front plate 5 and the two side plates 7 are inserted into the groove.

[0068] The bottom plate 3 is composed of an upper plate 3a and ribs 3b (four in this example) on the lower side thereof. An opening 16 into which claws (not shown) of a forklift can be inserted and extracted is formed on the front-rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com