Special supporting device of cover head of nuclear island containment vessel made of steel and transportation method

A steel containment and supporting device technology, applied in the directions of transportation and packaging, packaging, loading/unloading, etc., can solve the problems of easy deformation, influence of the installation of the containment, poor transportation stability, etc., to shorten the construction period and save manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

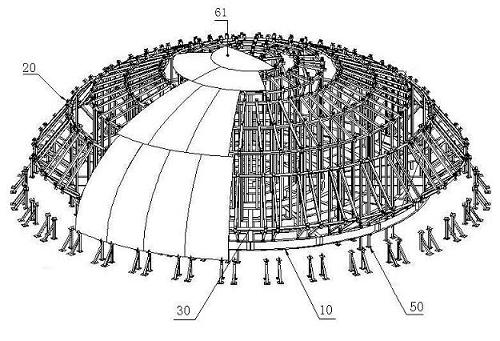

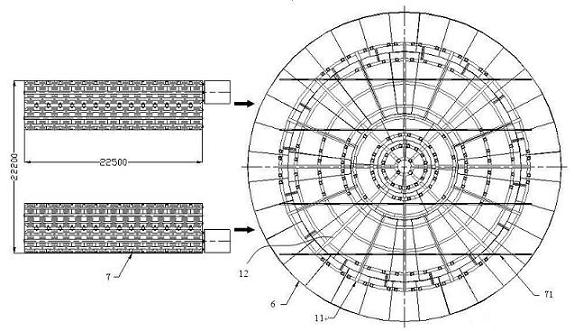

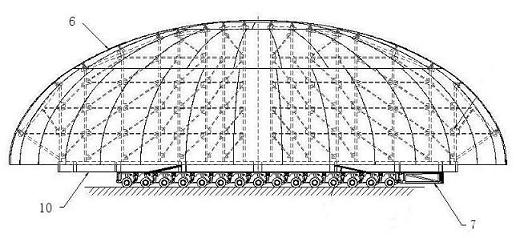

[0039] see Figure 1~Figure 4 , the special supporting device for transporting the top head of the steel containment vessel of the present invention is composed of a platform 10 , a bracket 20 and an edge fixing rod 30 .

[0040]The platform 10 is composed of eight concentric rings 11 and connecting rods 12. The rings 11 and connecting rods 12 are made of H-shaped steel and / or angle steel, and the two are connected into a whole by high-strength bolts. A large support 20 is arranged on the platform 10 , and its lower part is supported by a short column 50 . The short column 50 is arranged under the concentric ring 11 and is connected with the platform 10 by bolts. Its basic function is to keep the platform 20 at a certain height from the ground, which is convenient for transportation. Of course, in construction, other methods can also be used, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com