Glass plate packing pallet

A technology of glass plates and brackets, applied in packaging, external frames, transportation and packaging, etc., can solve the problems of glass plate damage, glass plate self-weight and increase, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments for carrying out the present invention will be described below with reference to the drawings. In addition, the following description is only description related to one Example of this invention, and this invention is not limited to these descriptions.

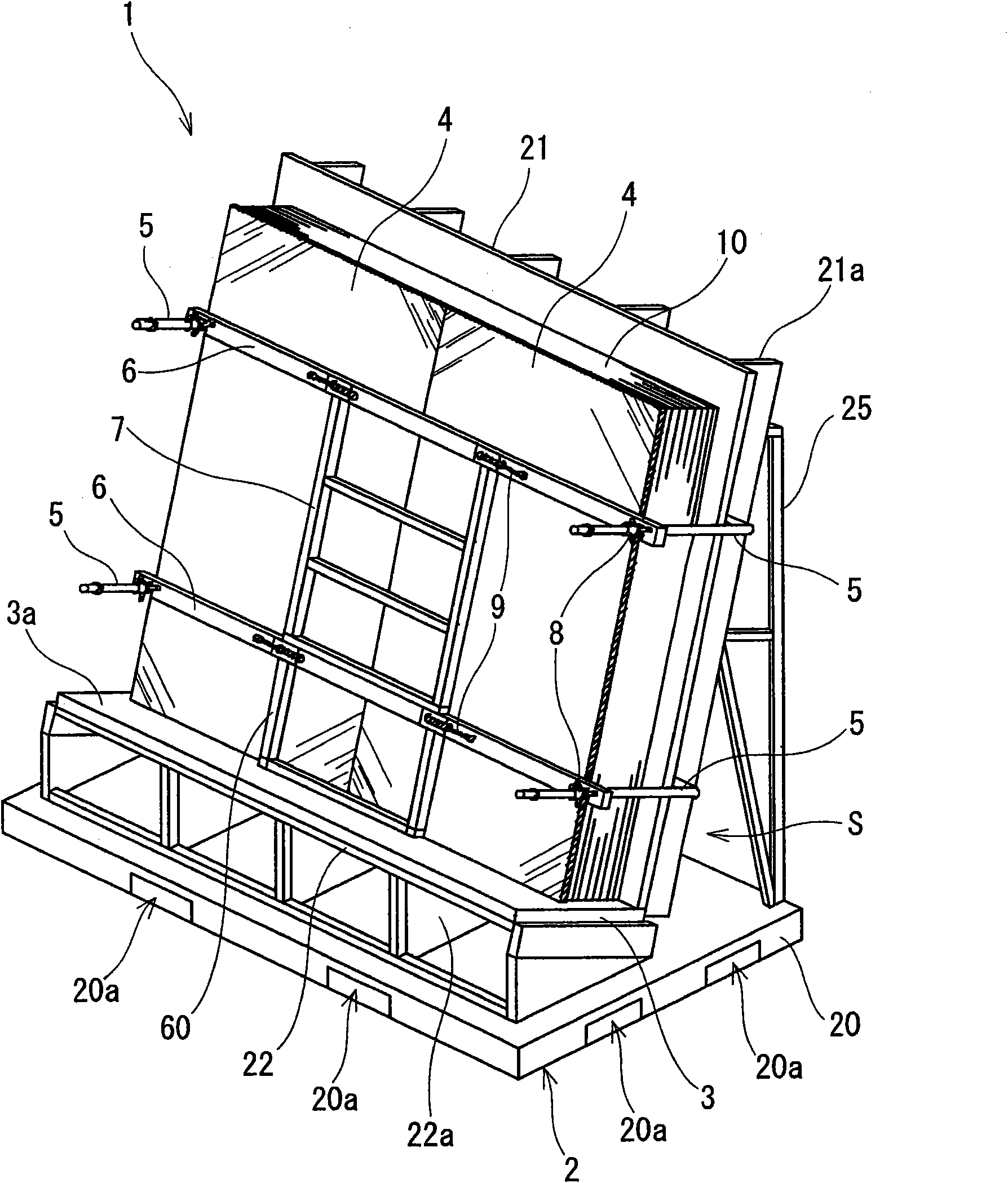

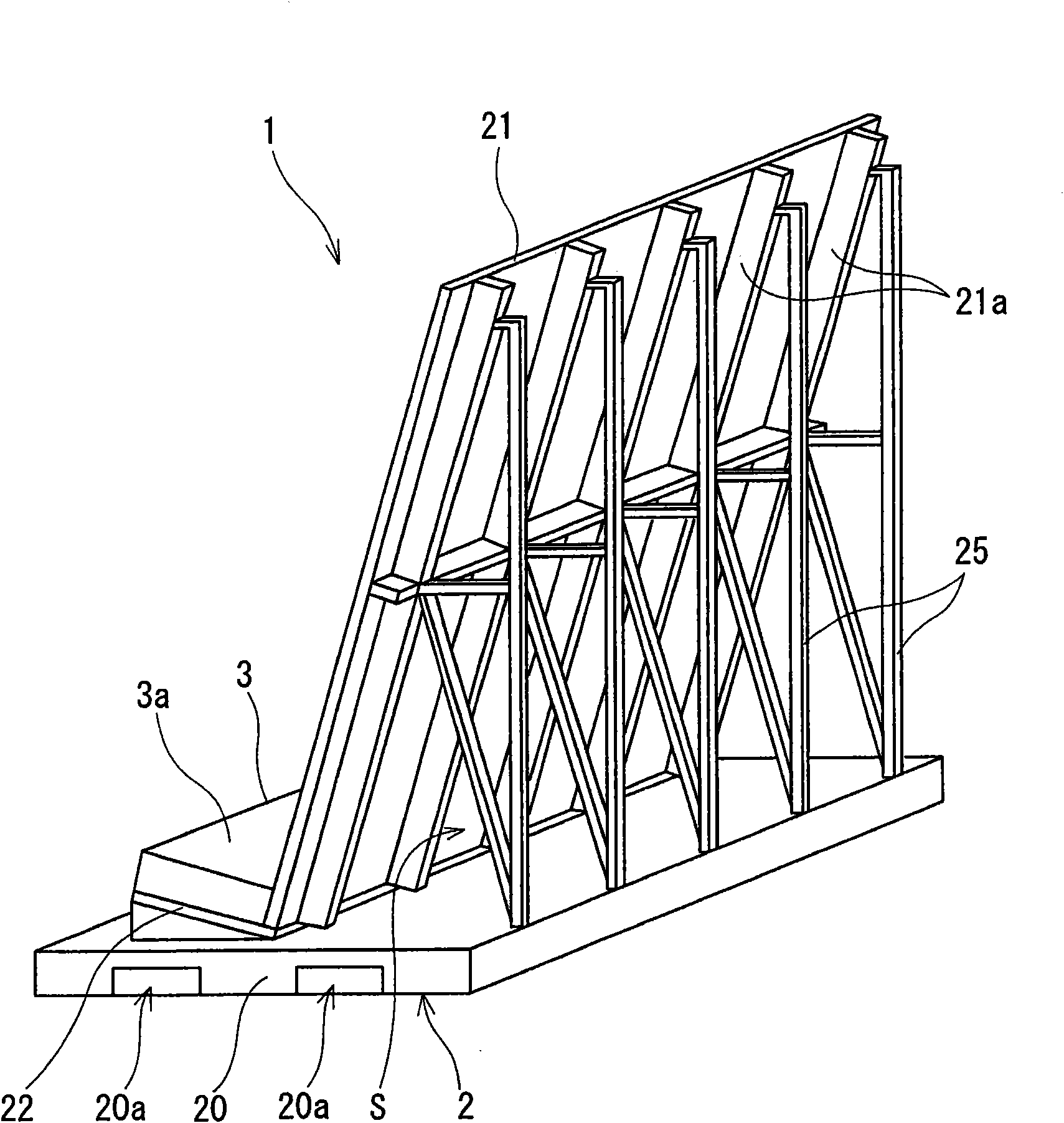

[0026] figure 1 and figure 2 The pallet 1 for glass plate packing (it abbreviates simply as "the pallet 1" hereafter) which concerns on one Embodiment of this invention is shown. The carrier 1 is used in bundles of large glass panes 10 . Normally, the glass plate 10 is mounted on the pallet 1 in a posture in which the longitudinal direction becomes the horizontal direction.

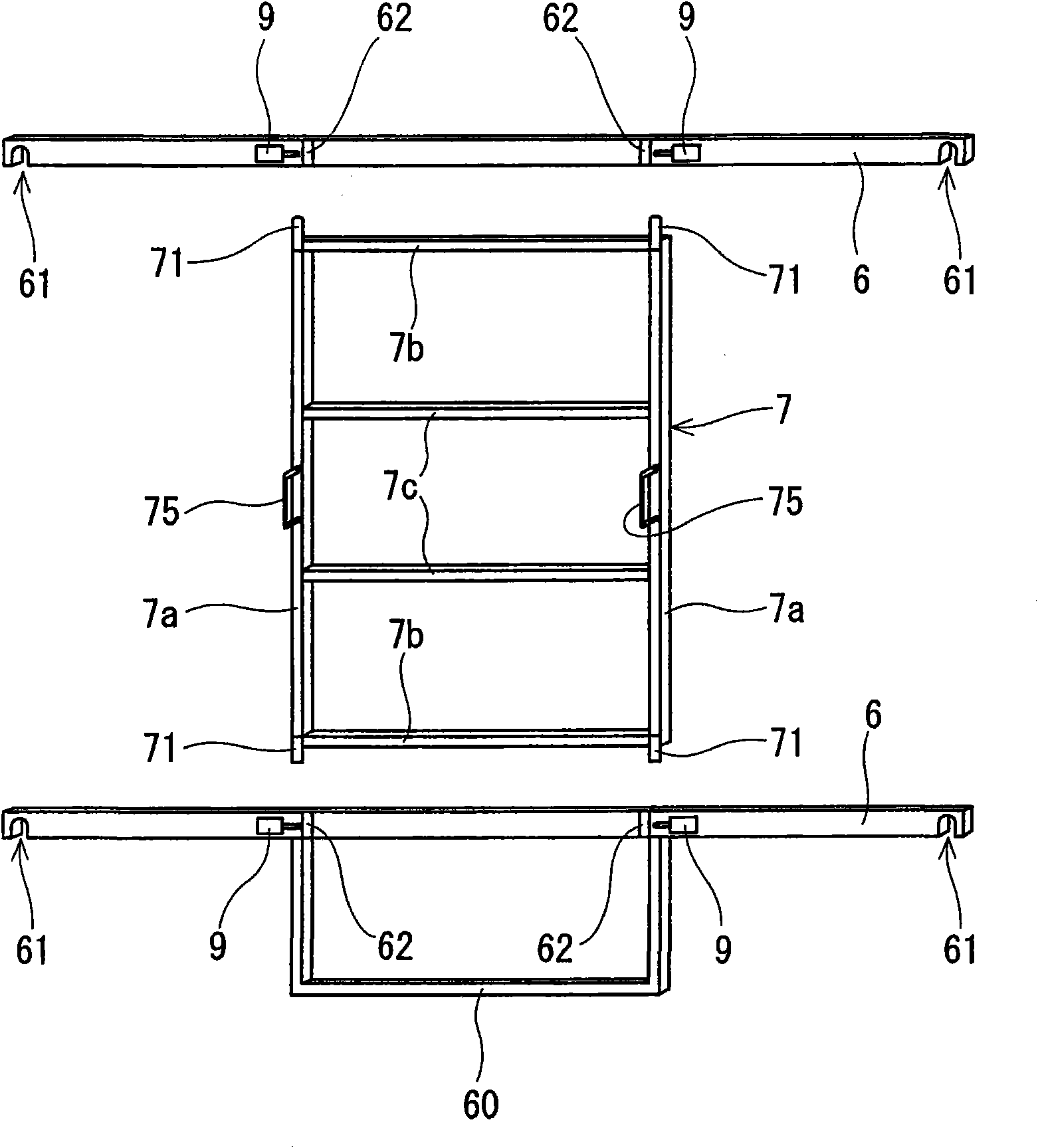

[0027] Specifically, the bracket 1 includes a main body 2 and a carrying part 3. The main body 2 has a base part 20, a mounting part 22 and a back panel 21 arranged on the base part 20, and the carrying part 3 is arranged on the mounting part 22. superior. In addition, in figure 2 In the figure, the glass plate 10 and the rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com