Transportation frame for big cabinet, and installation method

A technology of transportation frame and installation method, applied in transportation and packaging, external frame, large container, etc., can solve the problems of difficult operation and low efficiency, and achieve the effect of high transportation efficiency, convenient operation and lower transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

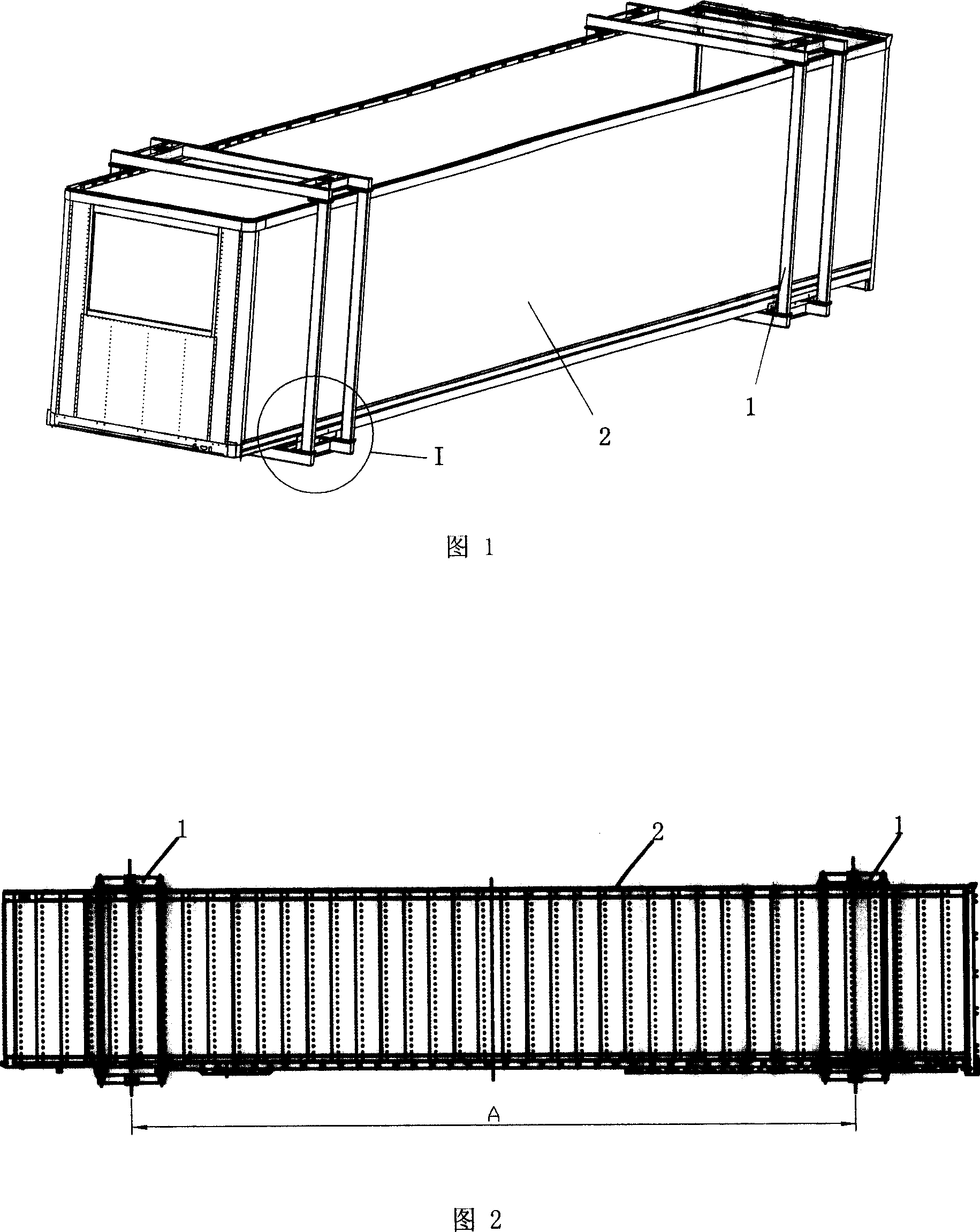

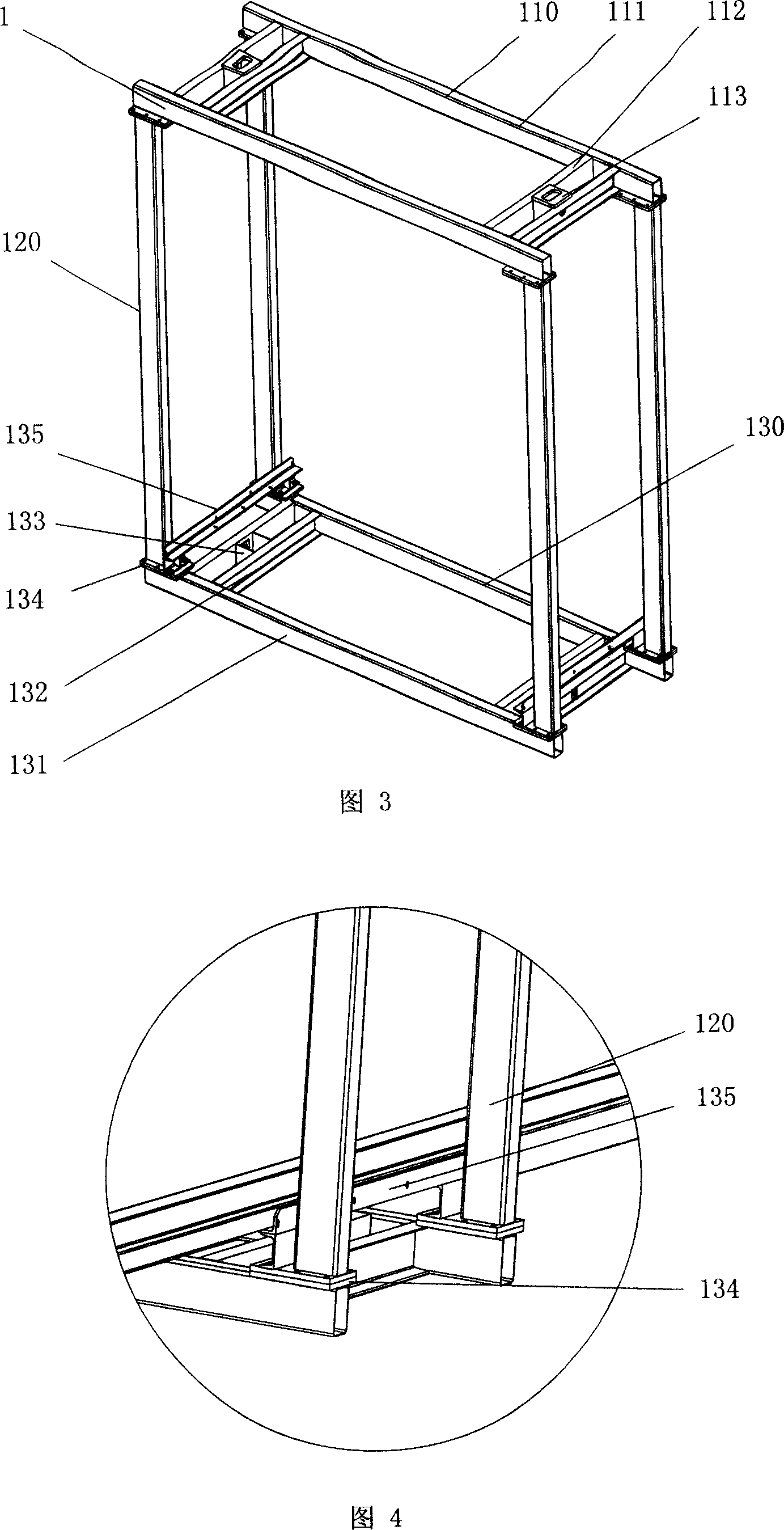

[0037] Fig. 3 to Fig. 6 show an embodiment of the large box transport frame of the present invention. As shown in Figure 3, this large-scale box transport frame includes an upper frame body 110, a lower frame body 130 and uprights 120, and four uprights 120 connect the two sides of the upper frame body 110 and the lower frame body 130 to form an interior suitable for accommodating and fixing the Transport the space of the large box body 2 (as shown in Figure 1).

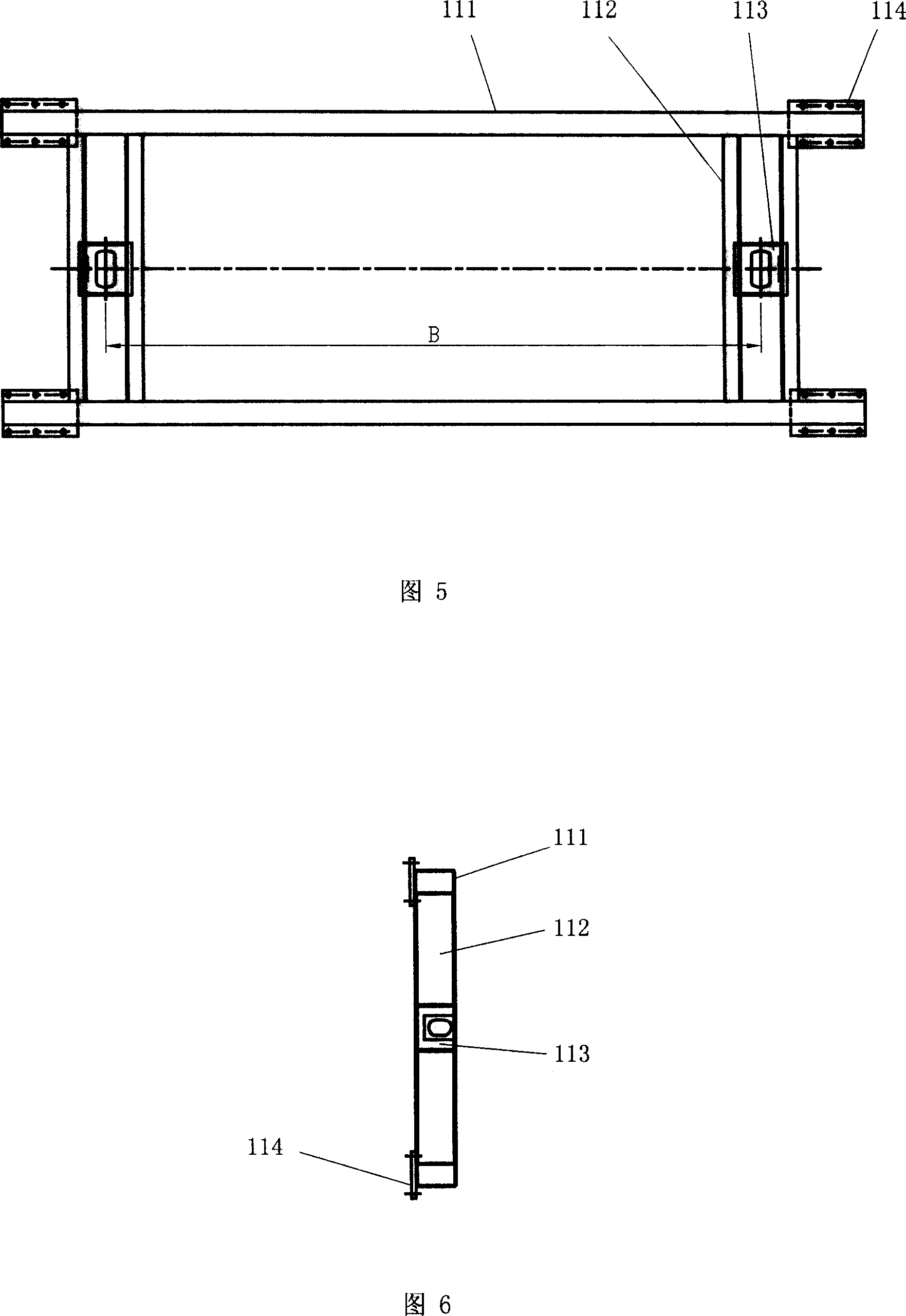

[0038] As shown in Fig. 3 and Fig. 5, the upper frame body 110 includes a pair of cross beams 111 arranged at intervals, respectively connecting the top corner support beams 112 at the two ends of the pair of cross beams 111, and the top corner support beams 112 connected to the middle of the top corner support beams 112. The corner fittings 113 and the connection plates 114 respectively connected to the lower sides of both ends of the beam 111 and provided with connection holes.

[0039] As shown in Fig. 5 and Fig....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com