Quantitative steel ball packaging machine

A ball loader and steel ball technology, applied in grain processing and other directions, can solve the problems of low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

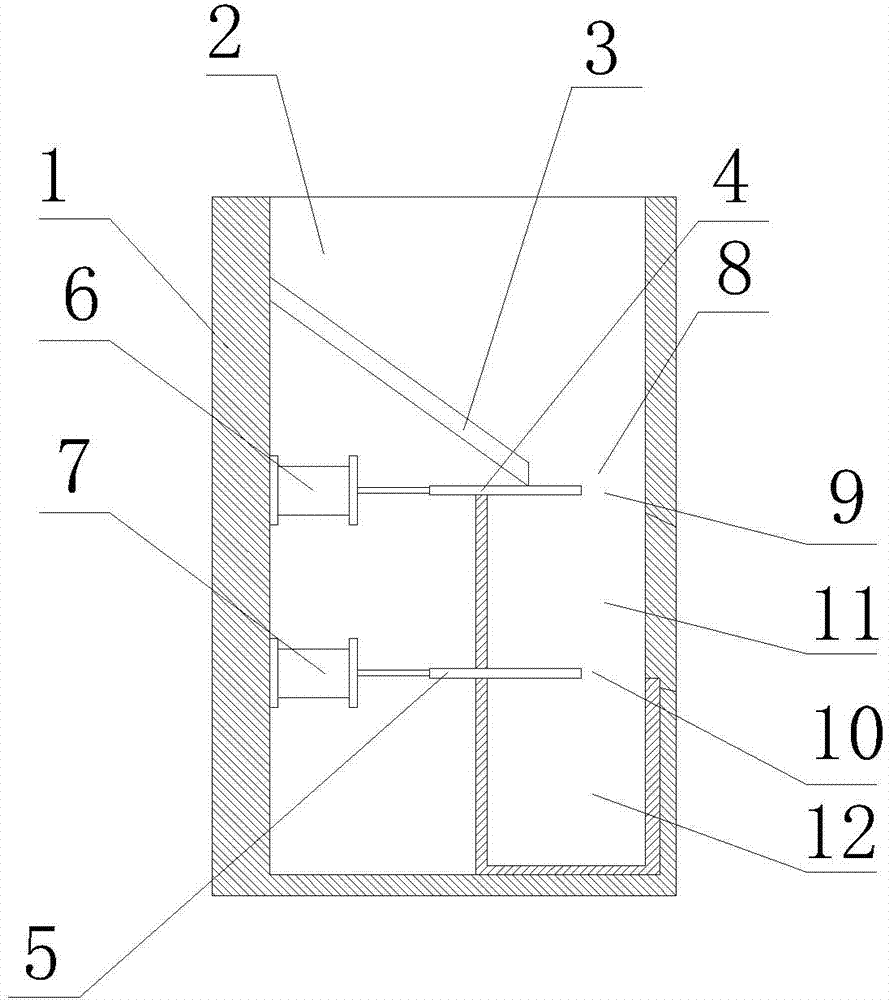

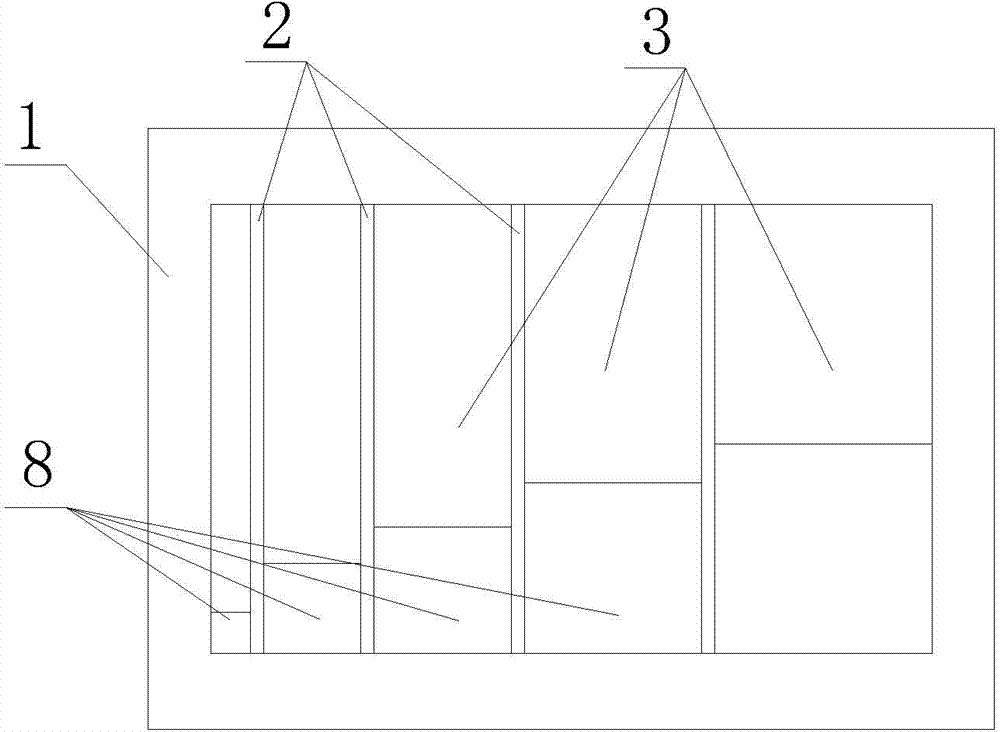

[0012] Such as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of a steel ball quantitative loading machine proposed by the present invention; figure 2 for figure 1 Schematic diagram of the top view of the local structure.

[0013] refer to figure 1 and figure 2 , a kind of steel ball quantitative loading machine that the present invention proposes, comprises frame 1, screening device and a plurality of distributing mechanisms, and screening device and dispensing mechanism are all installed on the frame 1; Screening device comprises multiple The partition boards 2 that are parallel to each other and vertically arranged, the upper end surface of the partition board 2 is located in the same plane, the two sides of the partition board 2 are fixedly connected with the frame 1, and the side of the partition board 2 is parallel to the frame 1 To the other side, the gap between the partition boards 2 gradually increases. The lower part of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com