Rotary label bagging device

A bagging device and labeling technology, which is applied in the field of label rotary bagging device, can solve the problems of low bagging efficiency and high labor cost, and achieve the effect of high bagging efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are all simplified schematic diagrams, and only schematically illustrate the basic structure of the present invention.

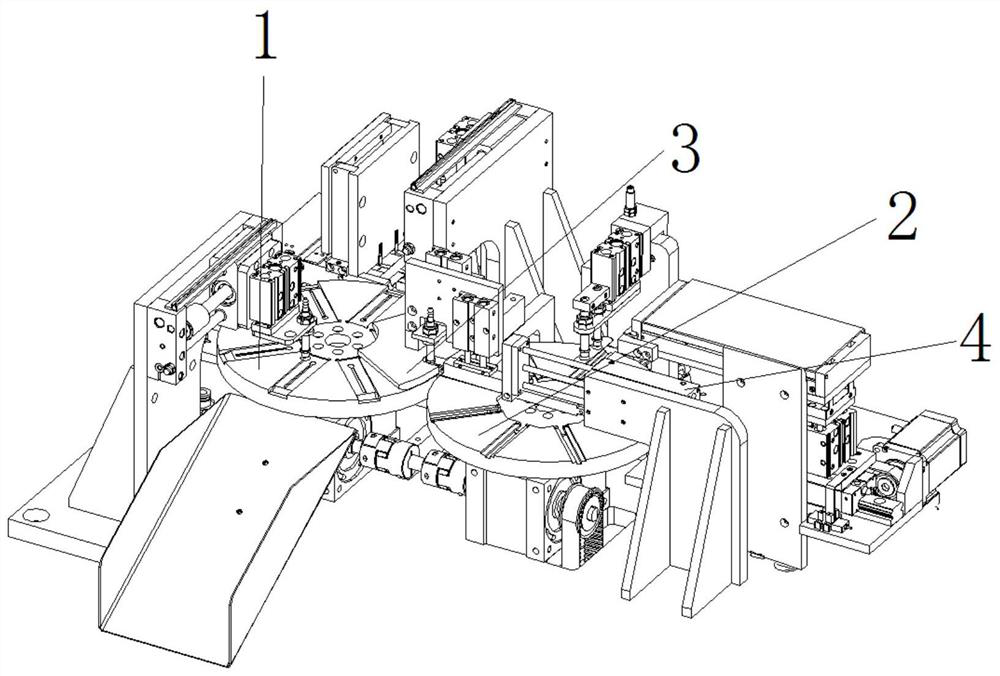

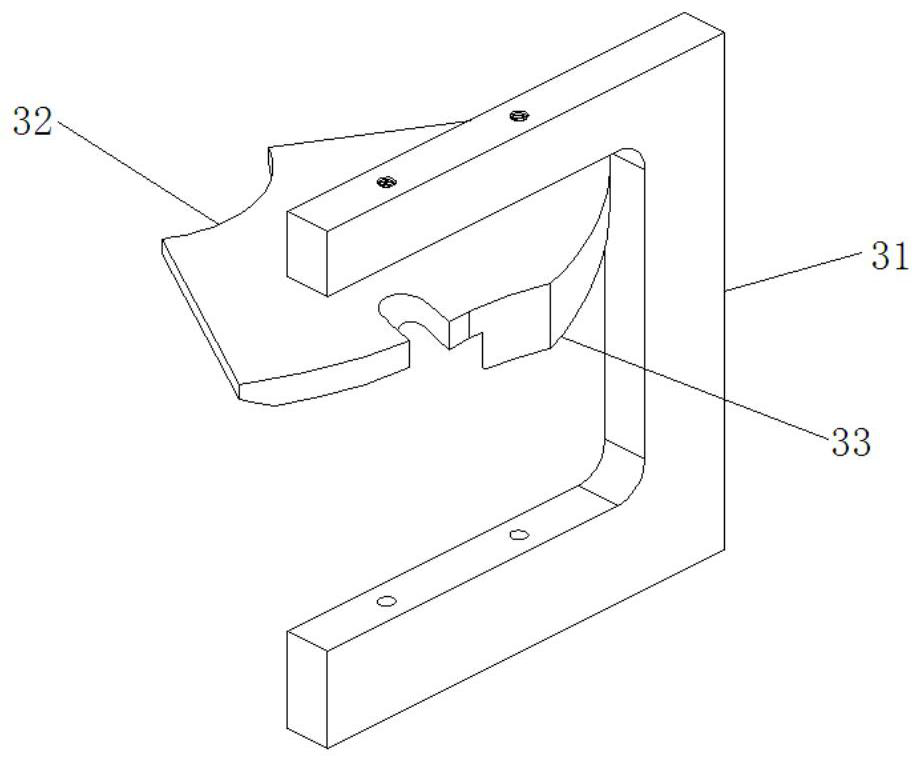

[0032] Such as Figure 1-Figure 4 As shown, the label rotary bagging device of the present invention is used to put the material core into the material bag, including the material bag indexing plate 1, the material core indexing plate 2, the guide bending mechanism 3, the bag opening and core pushing mechanism 4,

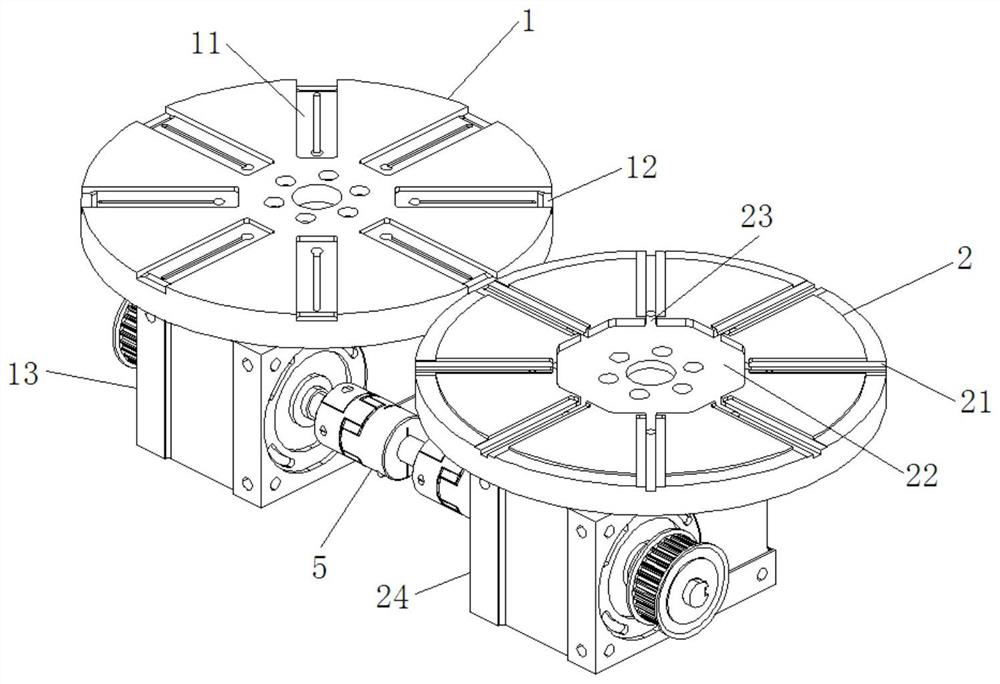

[0033] refer to figure 2 , the material bag indexing plate 1 is used to place the material bags, the top surface of the material bag indexing plate 1 is provided with a number of material bag grooves 11 along its radius position, and several material bag grooves 11 are evenly distributed along the surface of the material bag indexing plate 1 Specifically, there are eight material bag grooves 11, the material bag grooves 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com