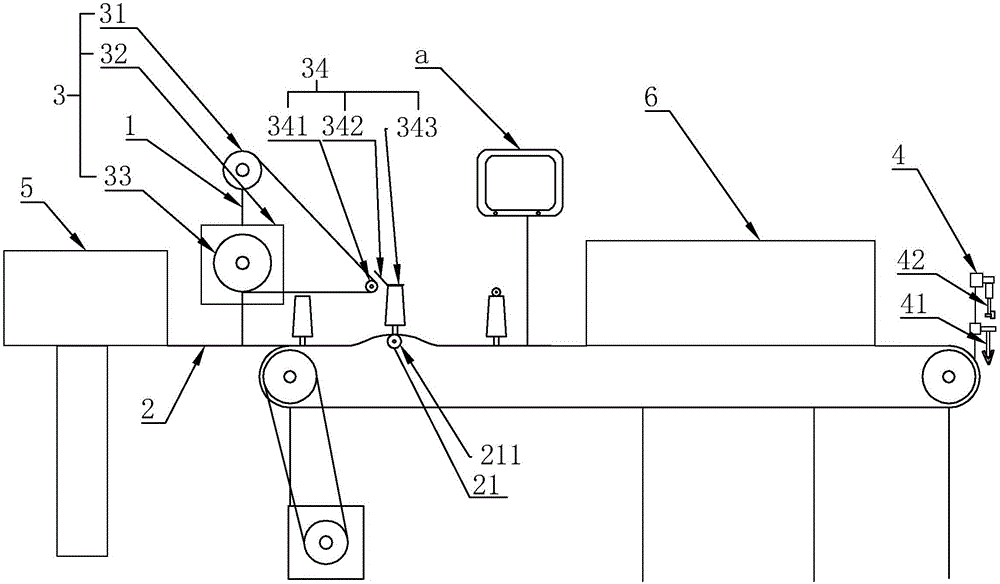

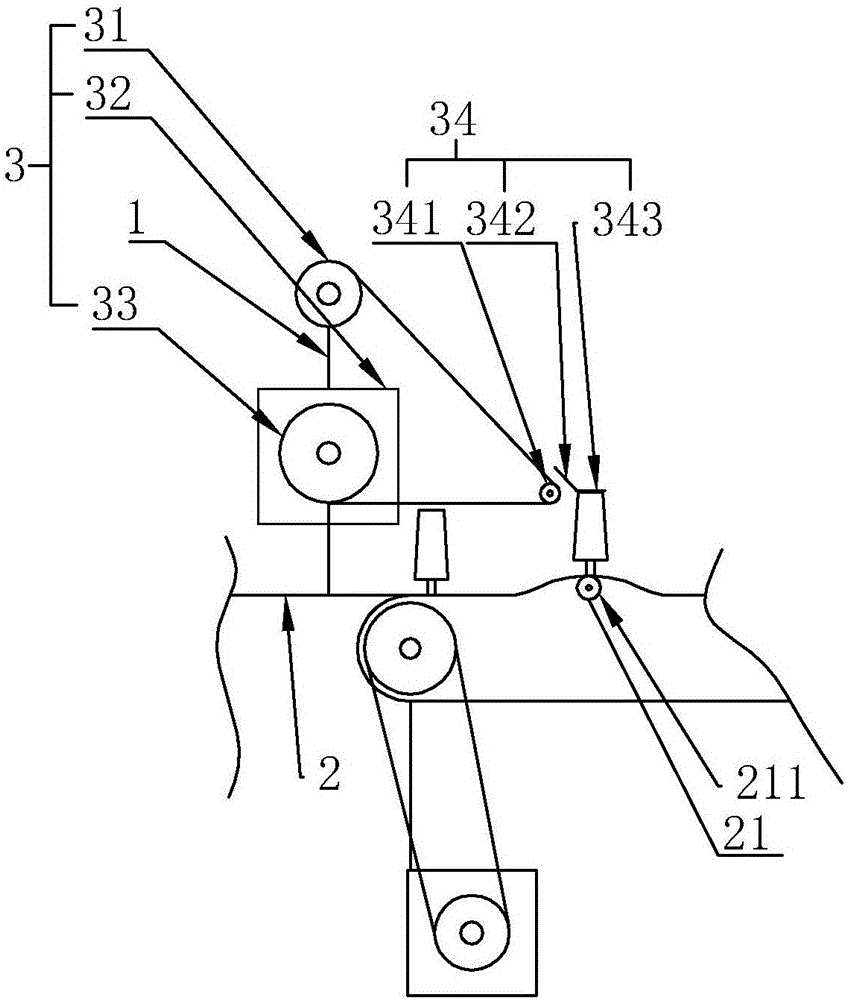

Full-automatic sewing thread packaging machine

An automatic packaging machine and sewing thread technology, applied in the direction of packaging machines, packaging, packaging protection, etc., can solve problems such as difficult to detect faults, main circuit paralysis, troublesome maintenance, etc., to avoid inaccurate operation, filter out interference signals, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

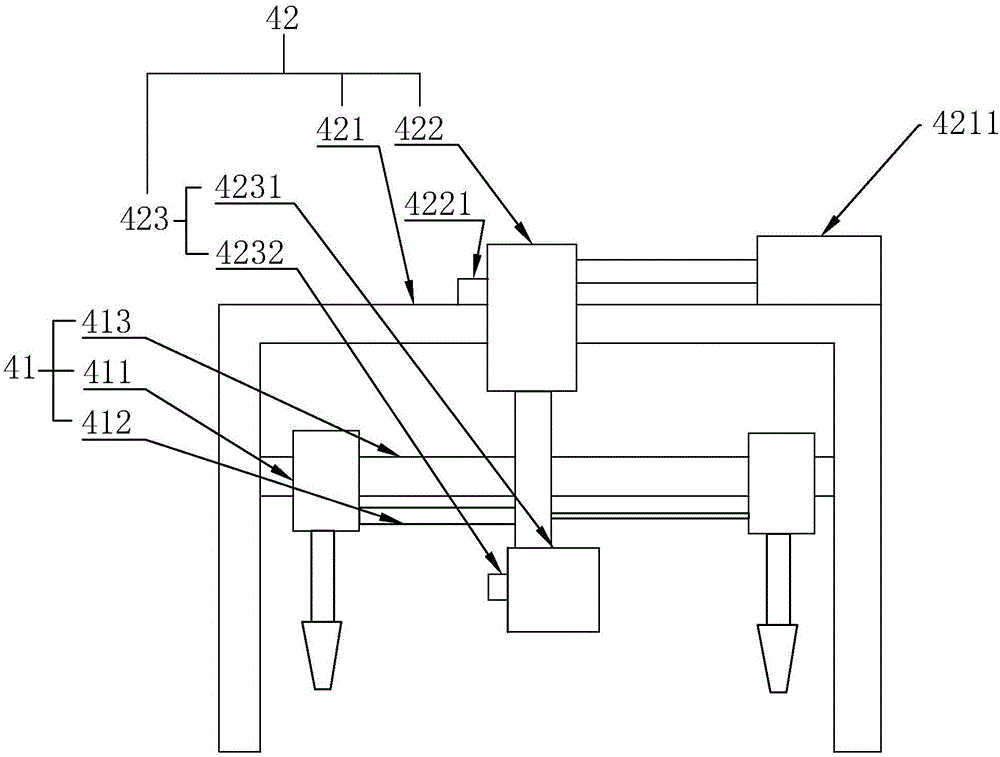

[0040] As an improved specific implementation, the main control circuit board a1 includes:

[0041] Main control chip a11, the main control chip a11 is a PLC programmable logic controller, which has multiple I / O interfaces for receiving and sending signals;

[0042] Auxiliary circuit a12, the auxiliary circuit a12 is coupled to the main control chip a11 to assist the work of the main control chip a1, and the main control chip a11 is set as a PLC programmable logic controller, which is a commonly used controller at present , used here, the main control effect can be well realized, and the structure of the auxiliary circuit a12 is simple and convenient, which is the same as the existing one.

[0043] As an improved specific implementation manner, the first isolation circuit a2 includes:

[0044] An isolation relay a21, the switch part of the isolation relay a21 is coupled between the power supply and the manipulator, and the coil part is coupled to multiple I / O interfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com