Automatic packing machine for polycrystalline silicon blocky bulk materials

An automatic packaging machine and polysilicon technology, applied in packaging, transport packaging, transportation and packaging, etc., to avoid damage to material bags and surface defects of polysilicon, avoid material pollution, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

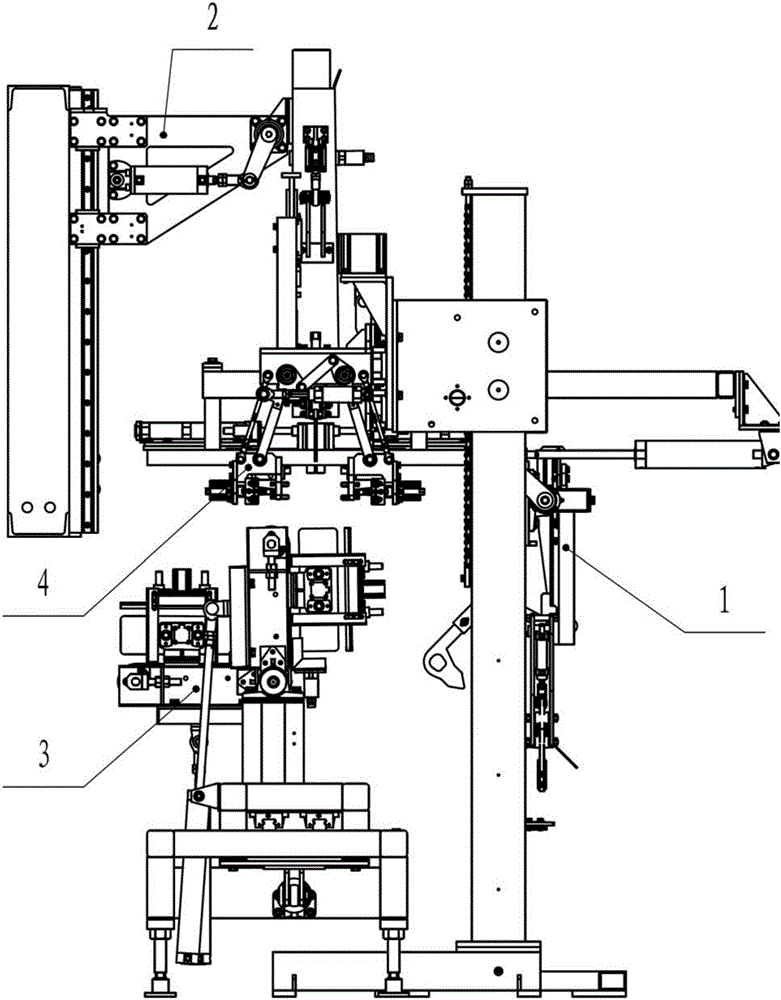

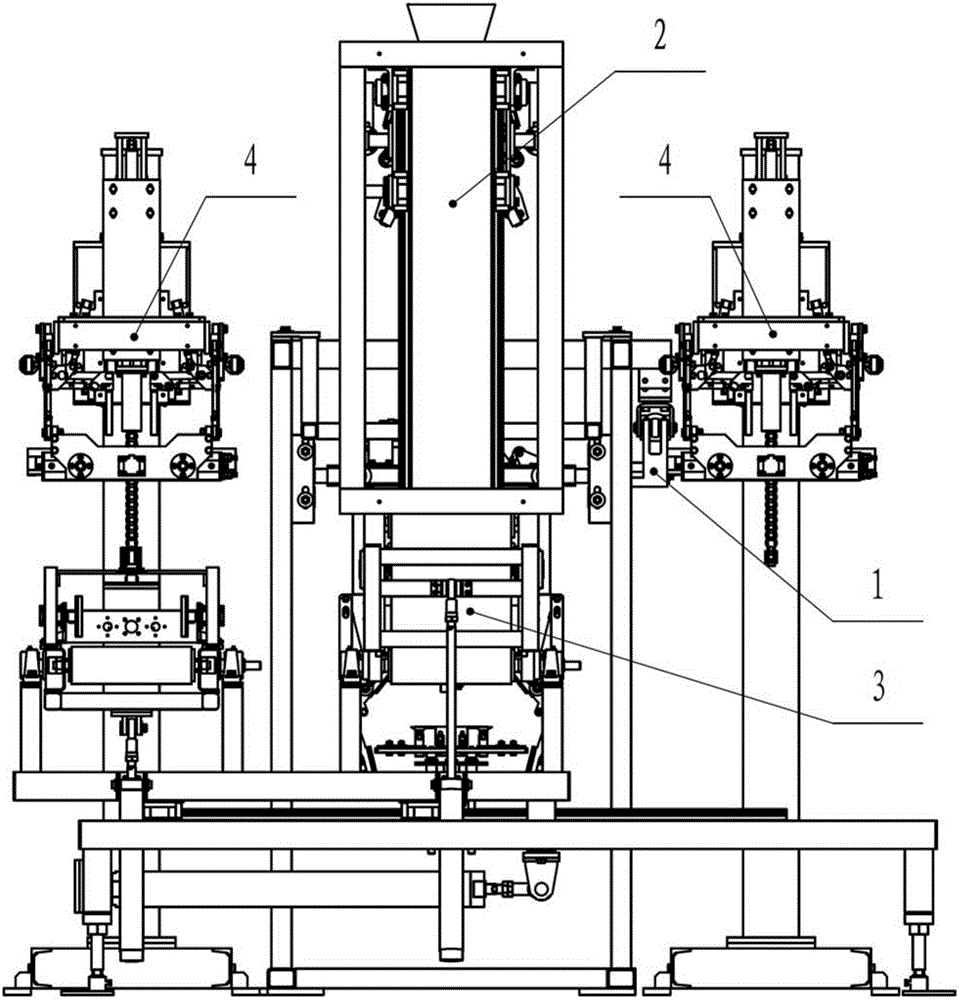

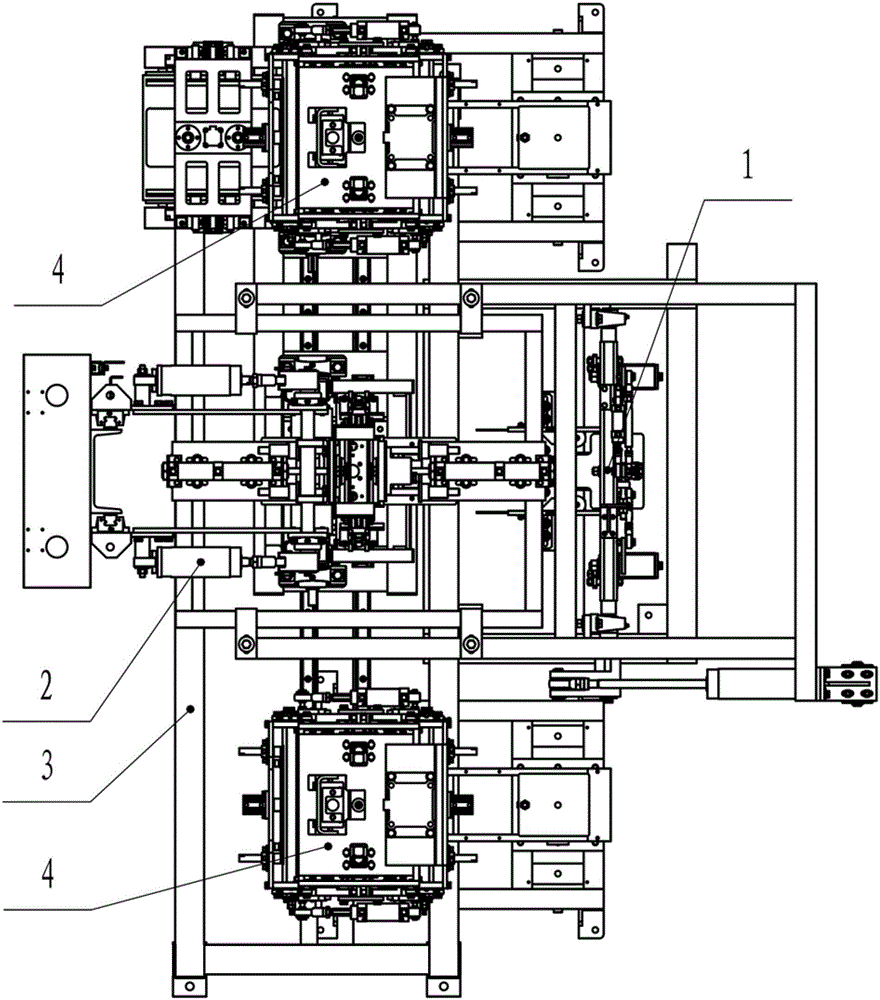

[0036]The specific embodiment of the present invention sees Figure 1 to Figure 12 , an automatic packaging machine for bulk polycrystalline silicon, which includes a bag feeding mechanism 1, a bagging mechanism 2, a material bag shaping mechanism 3, and a material bag sealing mechanism 4, and the bagging mechanism 2 includes a vertically liftable blanking cylinder 26. The blanking cylinder 26 has a rectangular parallelepiped shape, and the cross section of the blanking cylinder 26 is rectangular. The bag supply mechanism 1 includes a bag clamping mechanism 13. The bag clamping mechanism 13 is located directly below the vertical axis of the blanking cylinder 26. The bag clamping mechanism 13 The opening of the empty bag can be stretched into a rectangle similar to the cross-sectional shape of the blanking cylinder 26, and the blanking cylinder 26 can be lowered and inserted into the bottom of the empty bag that has opened the opening of the pocket. Below the mechanism 13, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com