Intelligent garbage can

A garbage can and intelligent technology, applied in the field of garbage cans, can solve the problems of manual replacement of garbage bags, small capacity, inconvenient replacement, etc., to achieve the effect of improving the convenience of life, increasing storage space, and extending time points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments and in conjunction with the accompanying drawings.

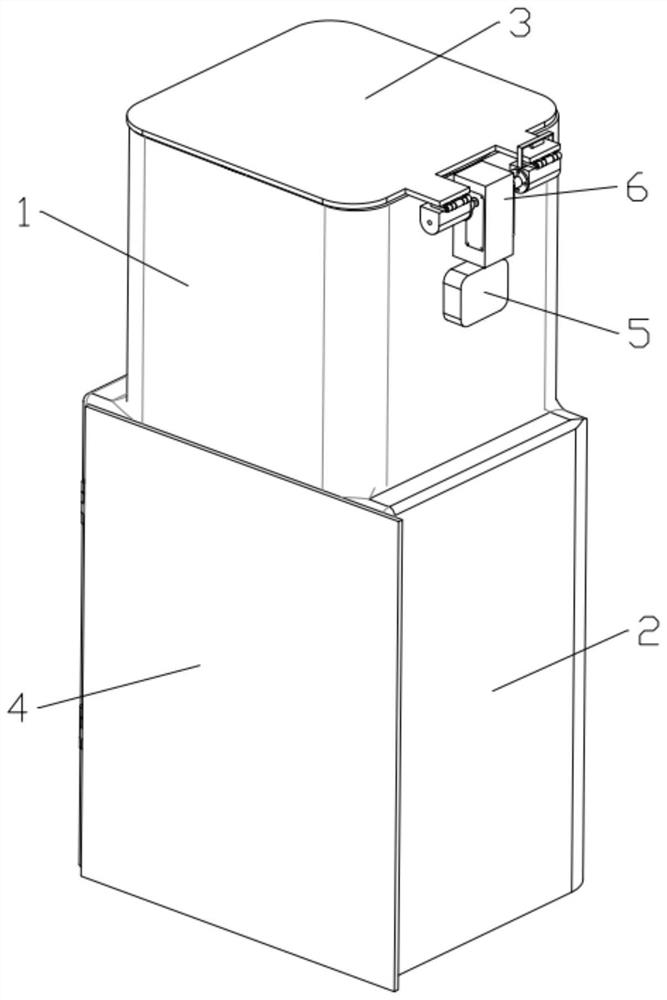

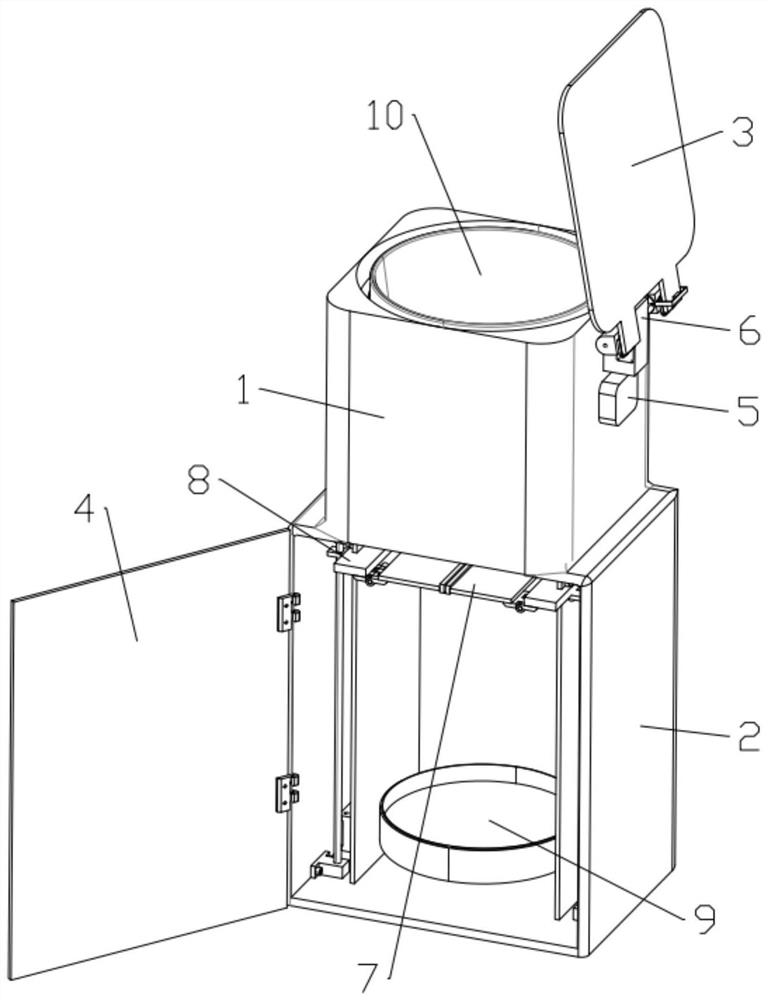

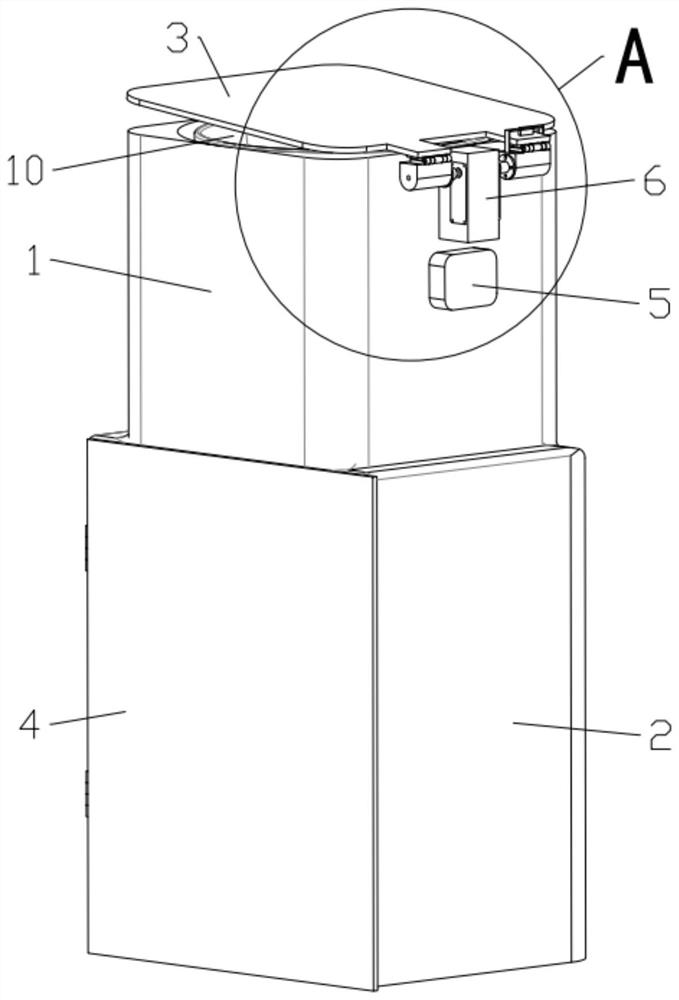

[0034] like Figure 1-7 As shown, in this embodiment, a smart trash can is provided, using a non-breakpoint garbage bag, which includes a storage device, a controller 5 , an overflow detection device 6 and a sealing cutting and opening assembly 7 . The storage device is specifically composed of a lower barrel 2 and an upper barrel 1 welded on the top of the lower barrel 2, and the bottom of the upper barrel 1 is communicated with the top of the lower barrel 2, and the upper barrel 1 is also provided with a diameter smaller than the upper barrel. 1. There is a gap between the inner barrel 10 and the upper barrel 1 for placing the garbage bag without breakpoints. When in use, the garbage bag without breakpoint is directly inserted into the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com