Automatic bag opening device for non-coated woven bags

A woven bag, no film coating technology, applied to the opening of woven bags. It can solve the problems of large production labor, dangerous equipment operation, poor working environment, etc., to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

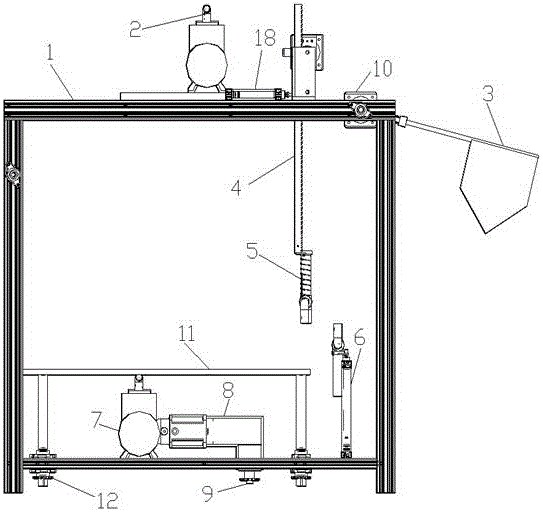

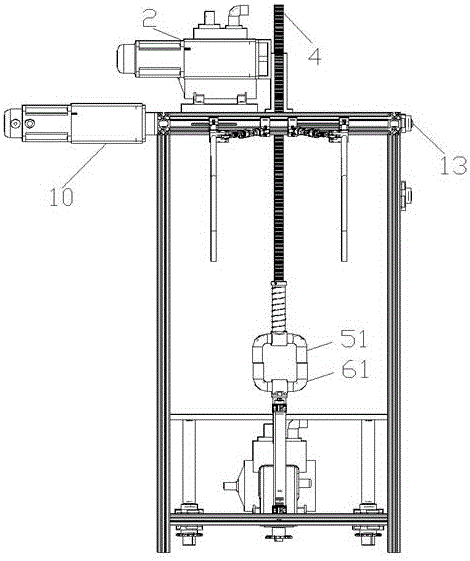

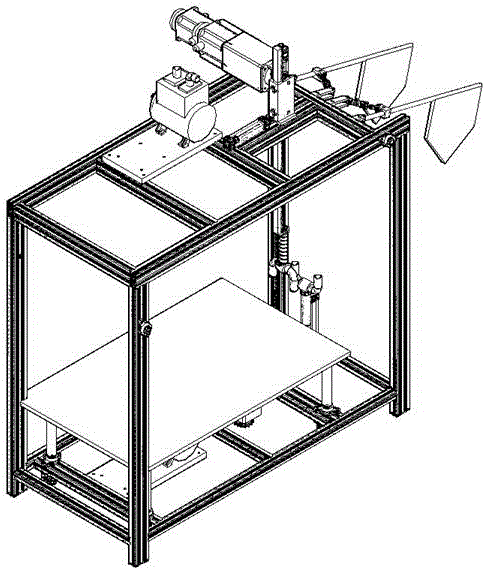

[0036] like Figure 1-7 As shown, it shows a specific embodiment of the present invention, as shown in the figure, a kind of automatic bag opening device for non-coated woven bags disclosed by the present invention includes a frame 1, which is equipped with The lifting pallet 11 for frame lifting; the lifting pallet is driven and lifted by the first driving assembly, and the first driving assembly includes the first motor 8; the frame is from left to right for the bag opening direction; the lifting The side of the pallet is provided with a lower suction cup assembly 6 driven up and down by a cylinder; the lower suction cup assembly provides air source power through a second air compressor 7 installed on the frame;

[0037] On the frame, an upper suction cup assembly 5 is installed at a position above the lifting pallet; the upper suction cup assembly includes the suction bag crank arm 4 and the upper suction cup 51 arranged at the bottom end of the suction bag crank arm; the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner circle diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com