Supercapacitor carbon conveying and dehydrating system

A supercapacitor carbon and vacuum dehydration technology, which is used in conveyor objects, carbon compounds, transportation and packaging, etc., can solve the problems of low dehydration rate, lack of material conveying devices, and residues in the dehydration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

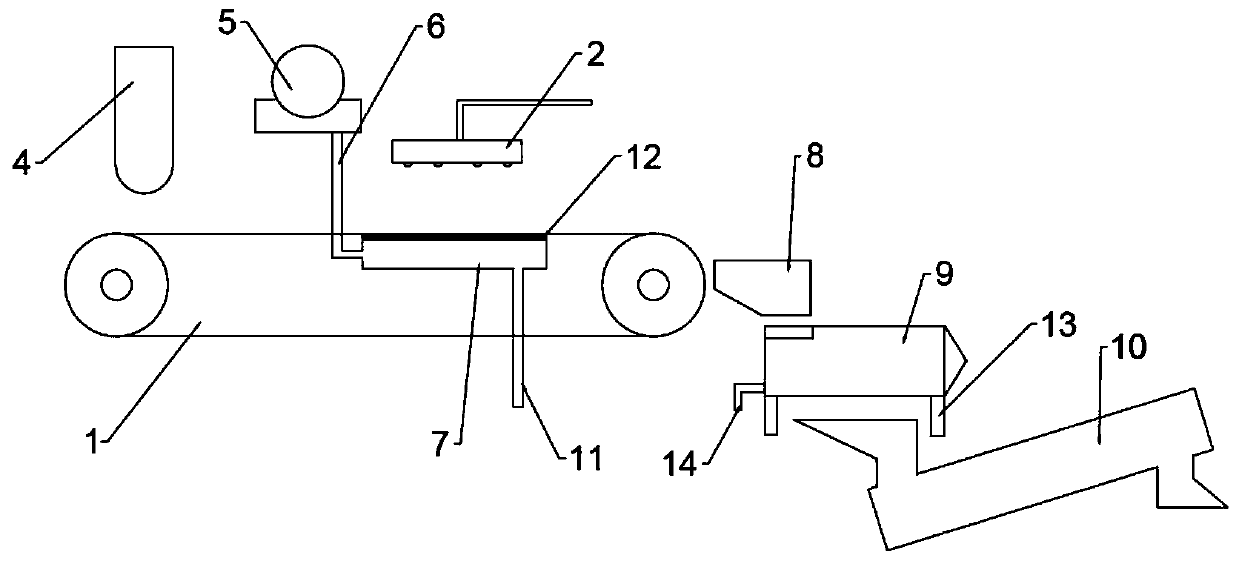

[0014] The present invention provides a supercapacitor carbon conveying and dehydration system during specific implementation, including a belt filter conveyor 1, a spray washing device 2, a dehydration drum machine 9 and a vacuum dehydration device 3, and the belt filter conveyor 1 runs in the direction of The top of the front end is provided with a feed tank 4, the spray washing device 2 is arranged above the middle part of the belt filter conveyor 1, and the vacuum dehydration device 3 includes: a vacuum pump 5, a connecting pipe 6 and a dehydration box 7, The dehydration box 7 is arranged below the filter cloth of the belt filter conveyor 1, and the nozzles of the dehydration box 7 and the spray washing device 2 are correspondingly arranged on the same vertical plane, and the belt filter conveyor 1 The end of the running direction is provided with a colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com