Automatic castable batching system

A technology of automatic batching and pouring material, applied in solid materials, mixer accessories, mixers, etc., can solve the problems of low efficiency, waste of manpower and material resources, and more dust, and achieve the effect of saving manpower and less dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

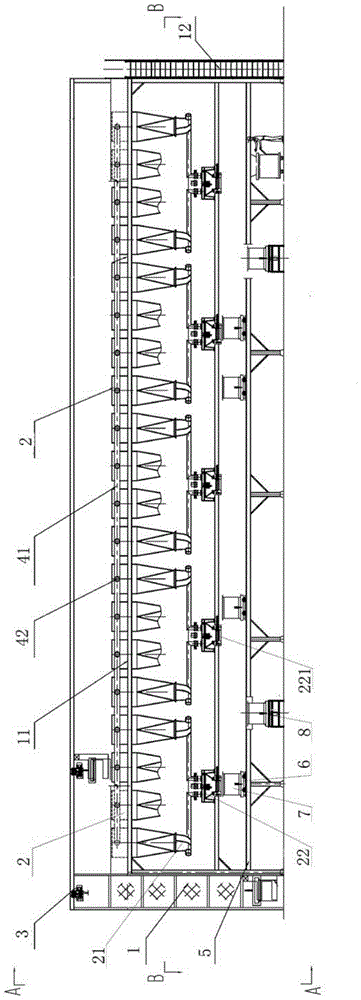

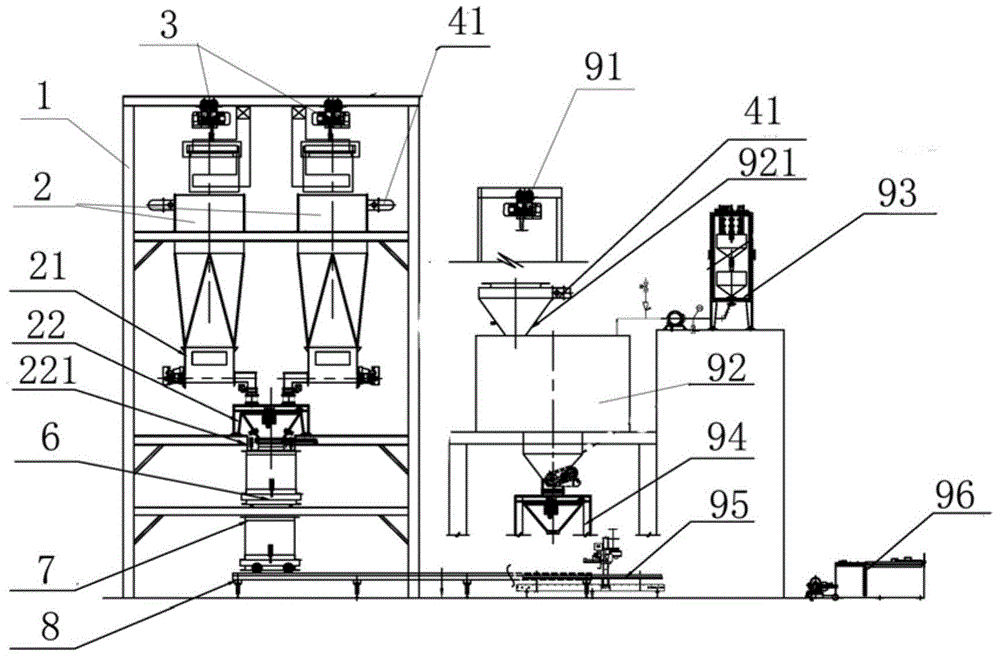

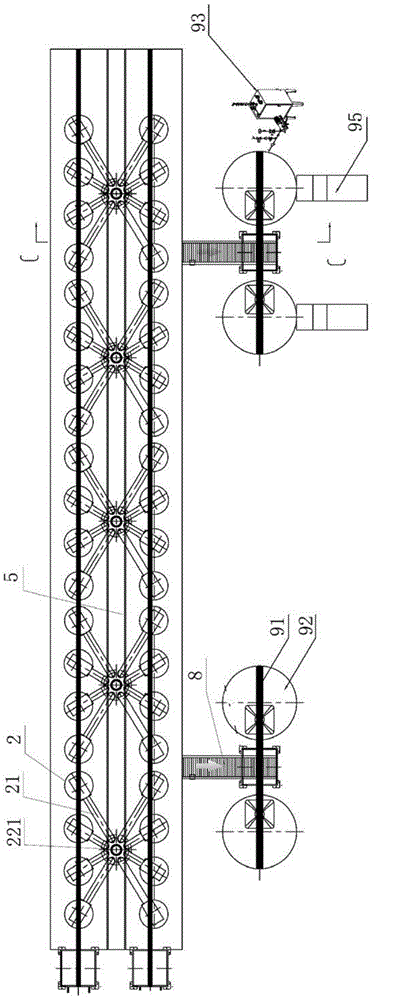

[0015] Such as Figures 1 to 4 Shown is an embodiment of a castable automatic batching system of the present invention, which includes a frame 1, a number of powder storage hoppers 2 arranged in two rows installed on the frame 1, and the powder storage hopper 2 There is a feeding port on the top and a feeder 21 for controlling the discharge at the bottom. A powder weighing device 22 is arranged at the discharge end of the feeder 21 on the frame 1; A feeding device 3 that can reciprocate along the arrangement direction of the powder storage hopper 2 is installed. The feeding device 3 can cooperate with the frame through a timing belt, a gear, etc., and drive the feeding device 3 through a timing belt drive or a gear drive. The feeding device 3 There is a lifting device for lifting the powder to the top of the powder storage hopper 2, and the lifting device can adopt an existing winch mechanism; on the frame 1, a dust removal device is installed at the feeding port of the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com