Slag extractor used for subway construction

A slag removal machine and subway technology, which is applied in the direction of traveling bridge cranes, cranes, mechanical equipment, etc., can solve the problems of laborious transportation, easy safety accidents, and car collisions, and achieve the effect of improving work efficiency and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

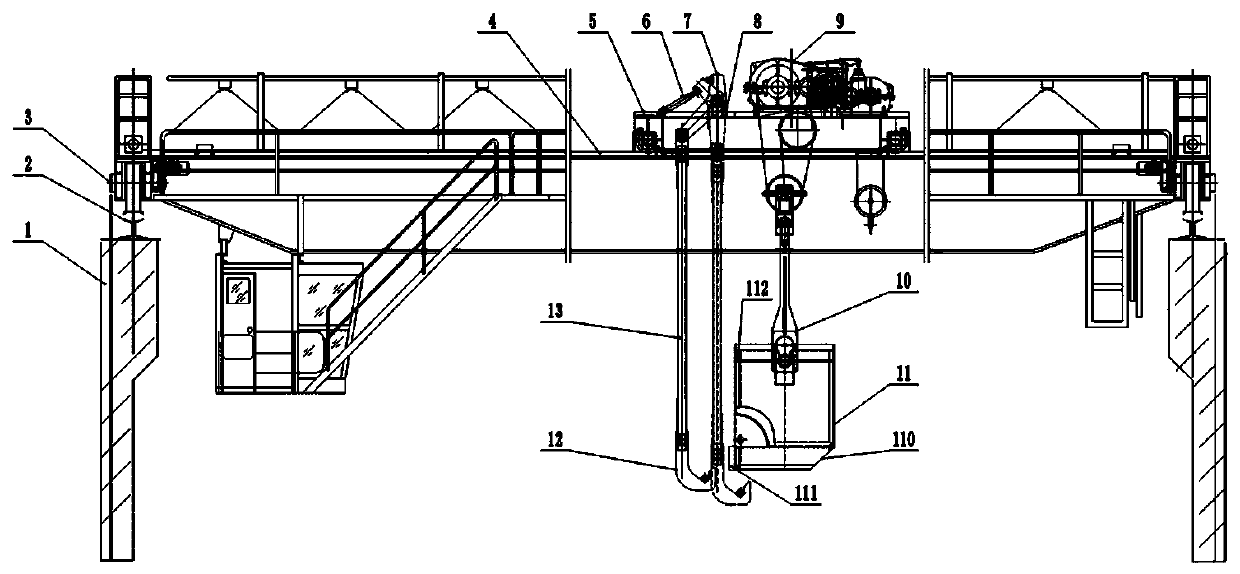

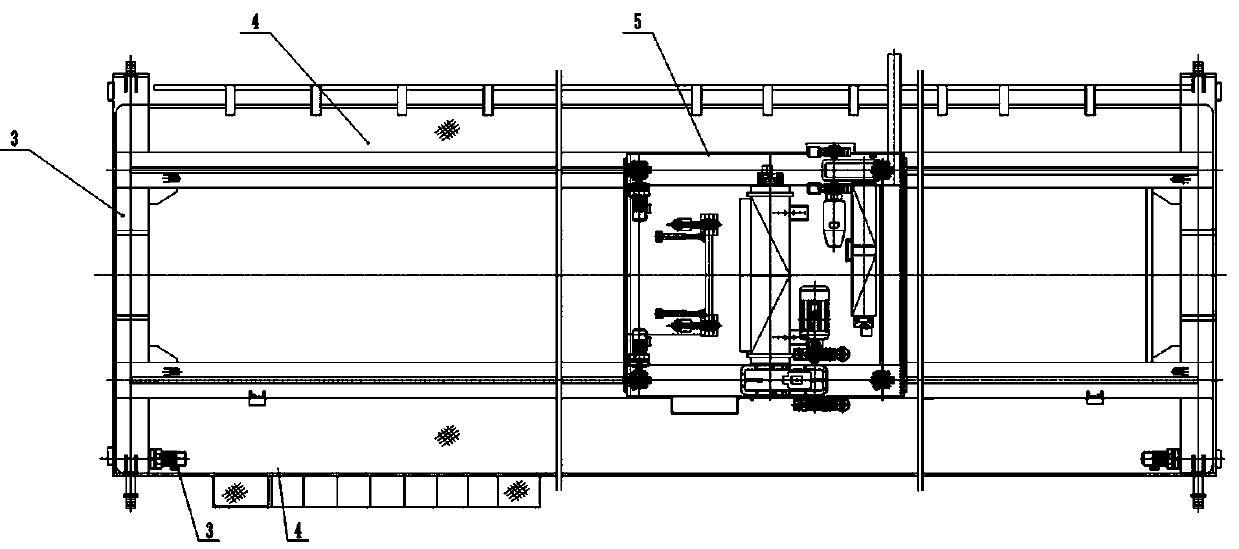

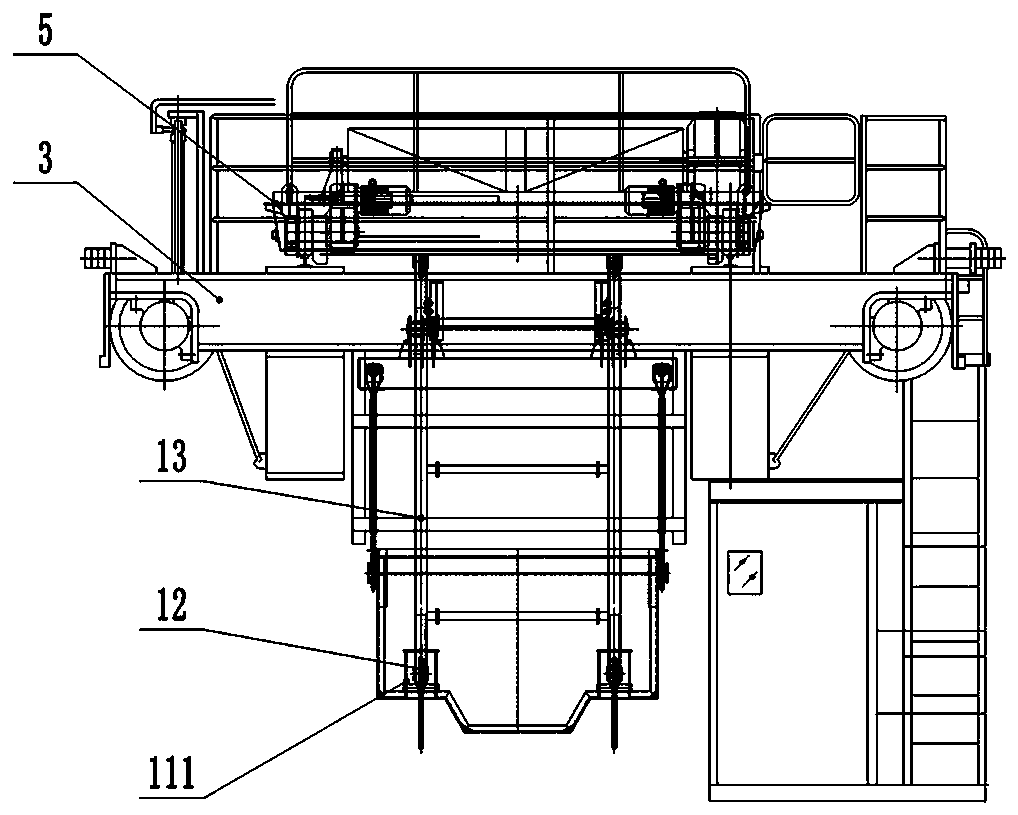

[0021] Such as Figure 1-3 Shown, a kind of slag machine that is used for subway construction comprises bridge frame 4, is provided with cart 3 at the bottom of both ends of bridge frame 4, is provided with the trolley 5 that can move along bridge frame 4 on bridge frame 4, on trolley 5 An electric hoist 9 is provided, the trolley 3 includes a drive motor and wheels, and the trolley 5 includes a drive motor and wheels, and the bridge frame 4 is provided with a trolley running track, etc. These structures are the same as those of the bridge crane, and will not be repeated here. A hopper 11 is hung on the hook 10 of the gourd 9, and the hopper 11 is fixedly connected with the hook 1. A tipping device for tipping the hopper 11 is provided on the trolley 5. The tipping device includes a first telescopic rod 6, an L-shaped connecting rod Rod 7, supporting device 8, vertical connecting rod 13 and hook 12, the first telescopic rod 6 is obliquely arranged, and one end of the first tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com