Full-automatic point welding machine

A spot welding machine, fully automatic technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of unfinished products, low quality of weldments, slow spot welding speed, etc., to achieve fully automatic operation, The effect of improving welding precision and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

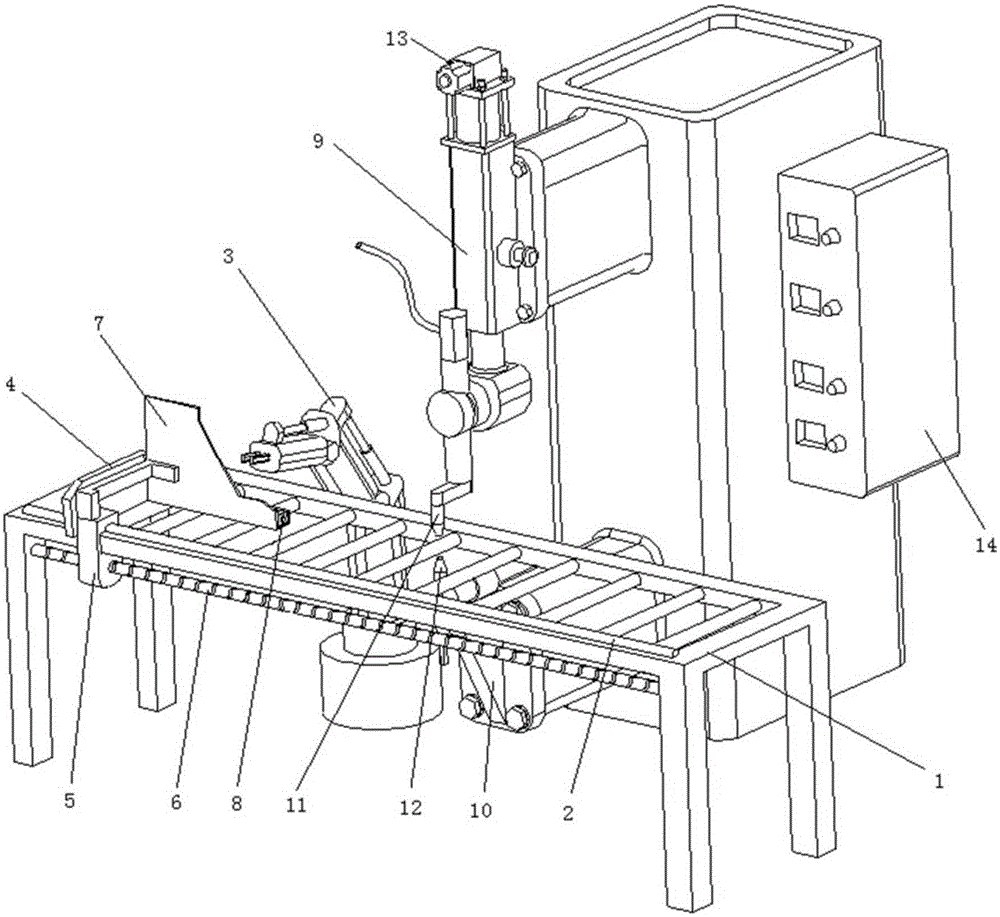

[0019] like figure 1 As shown, a fully automatic spot welding machine is used for welding the parts to be welded 8 on the thin plate parts 7 . The spot welding machine includes a welding table 1, a transverse guide rail 2, a welding machine body and a controller; the transverse guide rail 2 is installed on the welding table 1, and the welding machine body is installed on the welding table 1 one side, and is connected with the controller; the spot welding machine also includes a manipulator 3 mounted on one side of the welding table 1, and a movable clamp mounted on the lateral guide 2 The manipulator 3 and the clamping mechanism are respectively connected with the controller; the manipulator 3 places the thin plate 7 in the clamping mechanism, and the controller controls the The clamping mechanism moves horizontally along the lateral guide rail 2 to the position of the welding machine body. The welding machine body performs spot welding on the parts to be welded 8 and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com