Acrylic plate processing leftover material crushing equipment

A technology for crushing equipment and acrylic sheets, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve problems such as unfavorable processing and uneven crushing of acrylic materials, and achieve the effect of easy operation, favorable crushing operation, and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

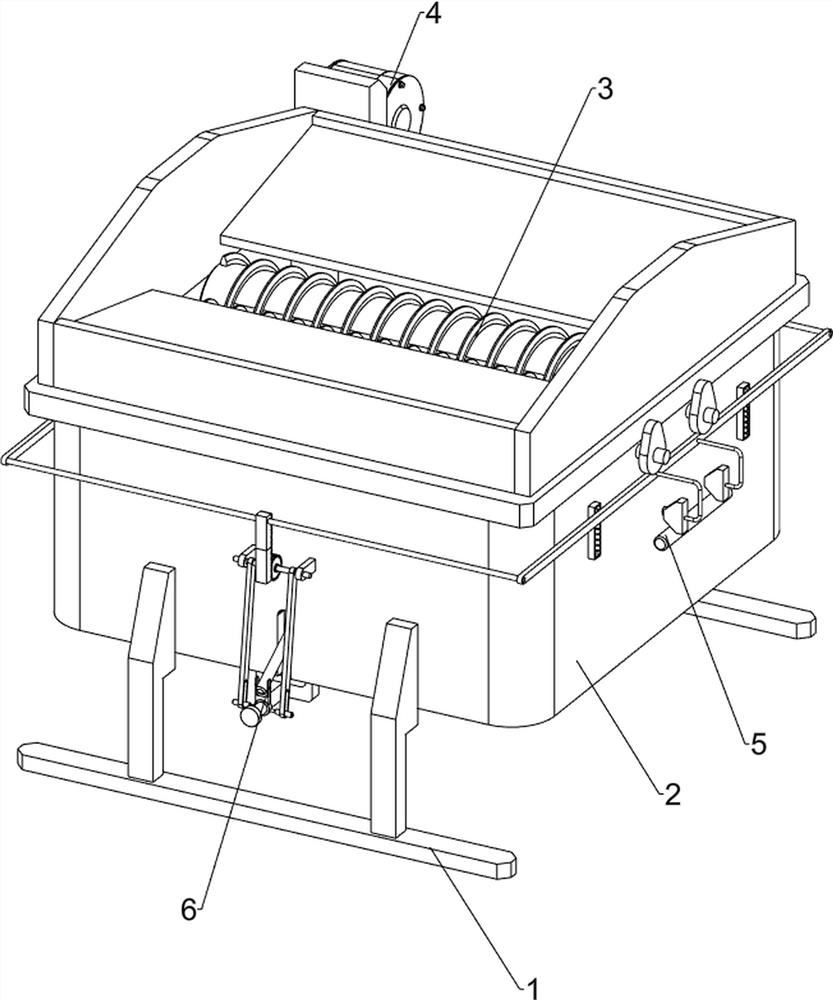

[0026] Such as figure 1 As shown, an acrylic board processing leftover material crushing equipment includes a foot 1, a processing box 2, a crushing mechanism 3 and a driving mechanism 4. The lower part of the processing box 2 is symmetrically provided with a foot 1, and the processing box 2 is provided with a crushing mechanism 3 , The outer wall of the processing box 2 is provided with a drive mechanism 4, and the drive mechanism 4 is connected to the crushing mechanism 3 through transmission.

[0027] When it is necessary to use this device to crush acrylic board scraps, the staff controls the driving mechanism 4 to work, and the driving mechanism 4 drives the crushing mechanism 3 to work, and then the staff crushes the acrylic board scraps and pours them into the processing box 2, and the crushing mechanism 3 For crushing operations, the device has a simple structure and is easy to operate.

Embodiment 2

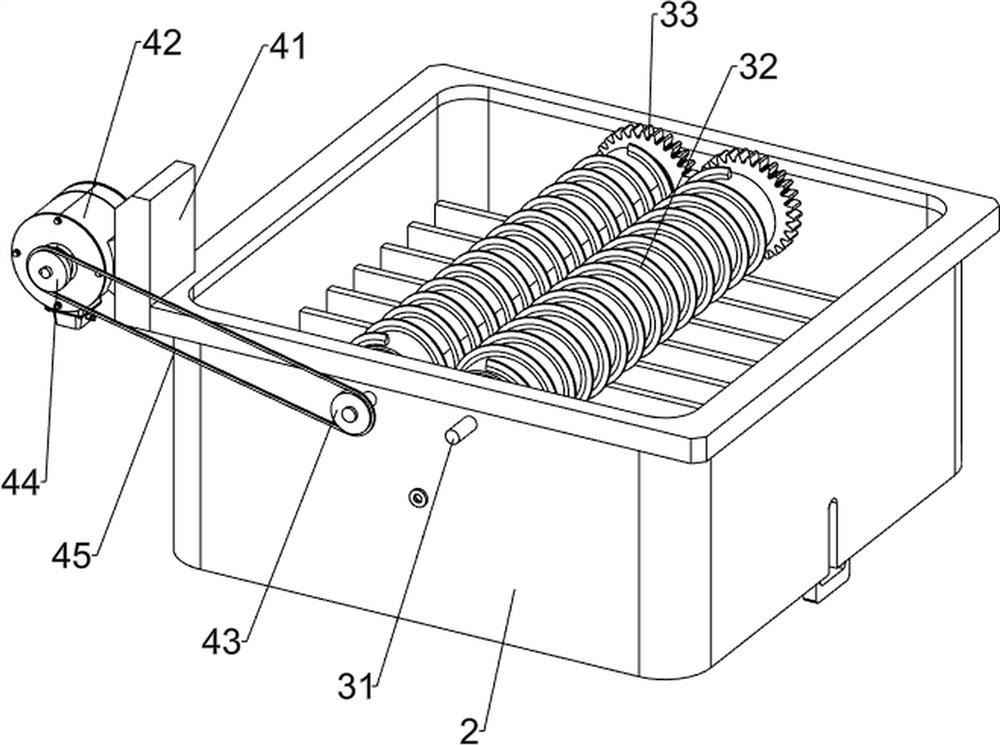

[0029] Such as figure 1 and figure 2 As shown, on the basis of Example 1, a crushing equipment for acrylic plate processing leftovers, the crushing mechanism 3 includes a first rotating shaft 31, a crushing drum 32 and a first gear 33, and the upper part of the processing box 2 is rotatably provided with two second A rotating shaft 31, the first rotating shaft 31 is provided with a crushing drum 32, the two crushing drums 32 cooperate with each other, and the right ends of the two first rotating shafts 31 are provided with a first gear 33, and the two first gears 33 mesh with each other.

[0030] The driving mechanism 4 includes a first fixed block 41, a servo motor 42, a first pulley 43, a second pulley 44 and a conveyor belt 45. The left part of the rear side wall of the processing box 2 is provided with a first fixed block 41, and on the first fixed block 41 A servo motor 42 is provided, a first pulley 43 is provided at the rear end of the first rotating shaft 31 on the l...

Embodiment 3

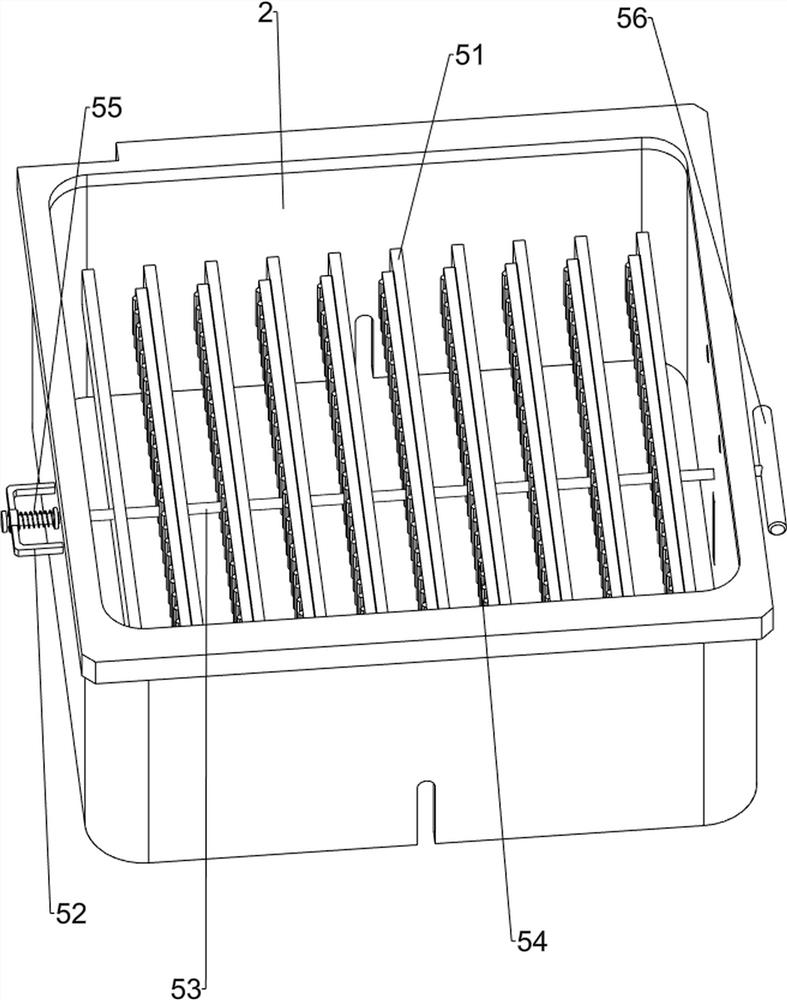

[0033] Such as image 3 , Figure 4 and Figure 5 As shown, on the basis of Example 2, a crushing equipment for acrylic plate processing leftovers, a crushing mechanism 5 is arranged in the middle of the processing box 2, and the crushing mechanism 5 includes a second fixed block 51, a guide sleeve 52, a slide bar 53, Pressing block 54, first elastic member 55 and top block 56, the second fixed block 51 is arranged at even intervals between the front and rear side walls of the middle part of the processing box 2, and the middle part of the left side wall of the processing box 2 is provided with a guide sleeve 52, and the guide sleeve Sliding type is provided with slide bar 53 in 52, and slide bar 53 runs through processing case 2 sidewalls and the middle part of the second fixed block 51, is provided with pressing block 54 evenly on the slide bar 53, is provided with between slide bar 53 and guide sleeve 52 The first elastic member 55 is a compression spring, and the right e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com