Environment-friendly horizontal crushing device for recycling building material waste

A waste recycling and pulverizing device technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of inability to pulverize, inconvenient unloading and transportation of powder materials, and reduce pollution and improve work efficiency. , The effect of easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified and described in detail below with the accompanying drawings.

[0025] Below in conjunction with accompanying drawing, structure of the present invention is described in detail:

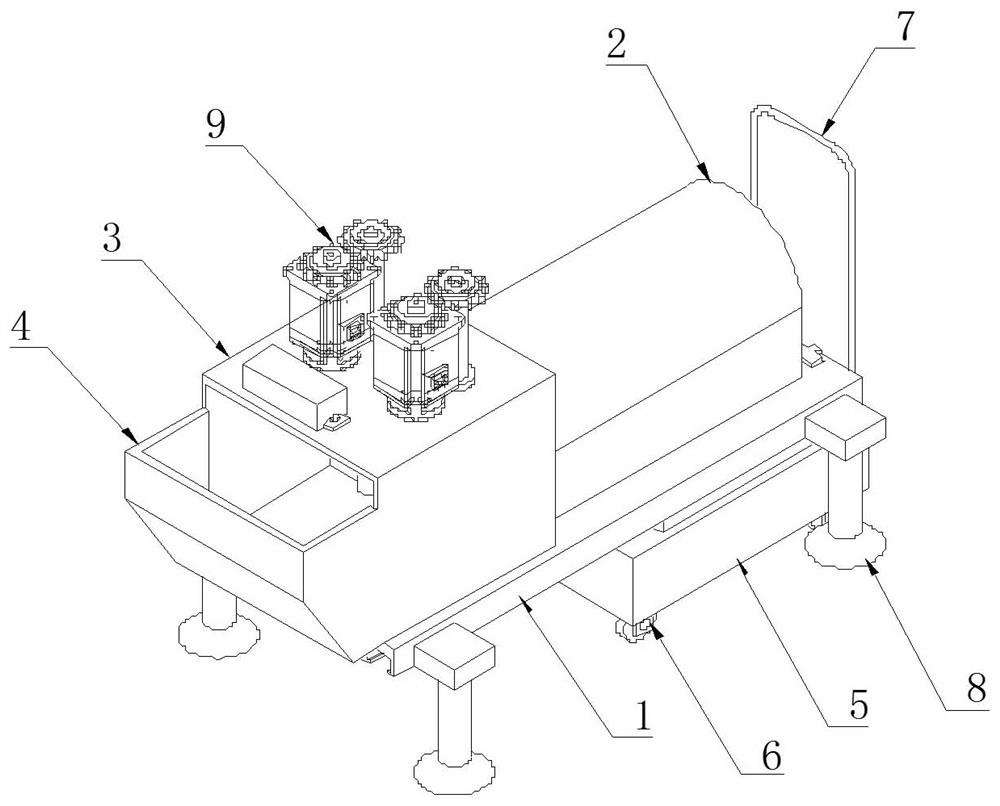

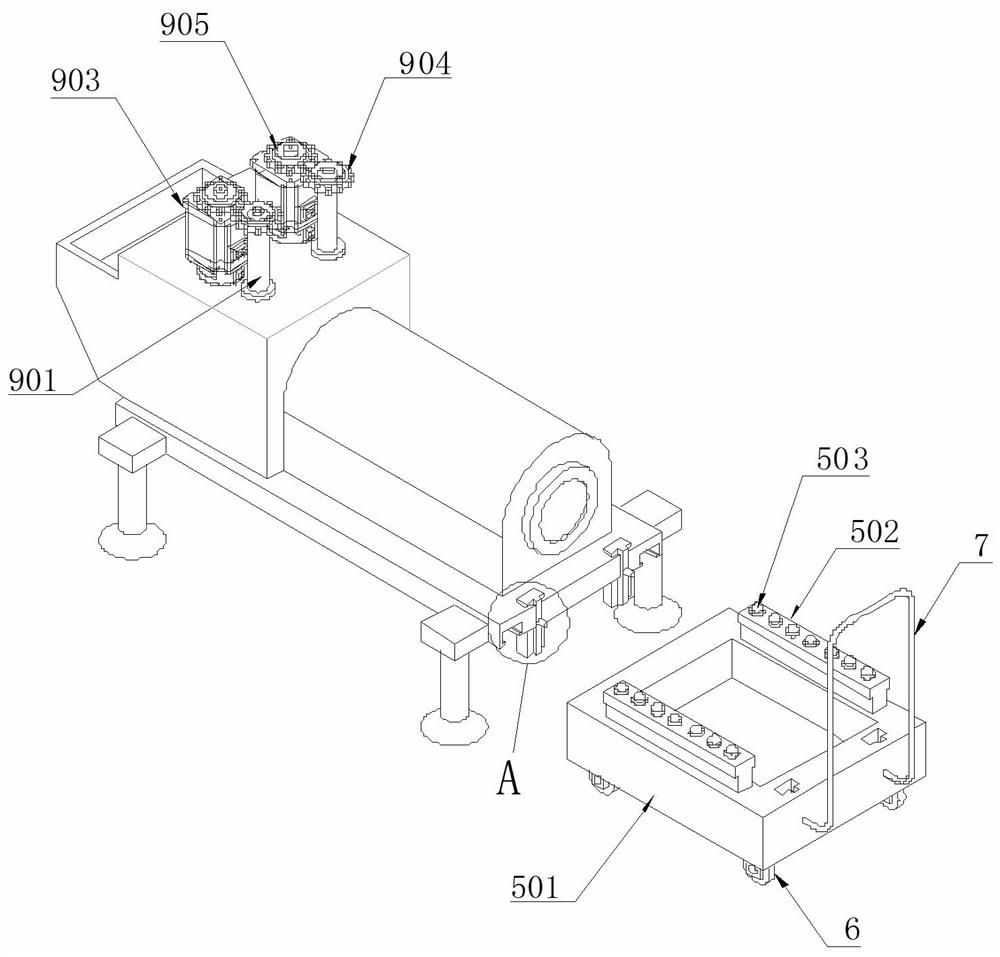

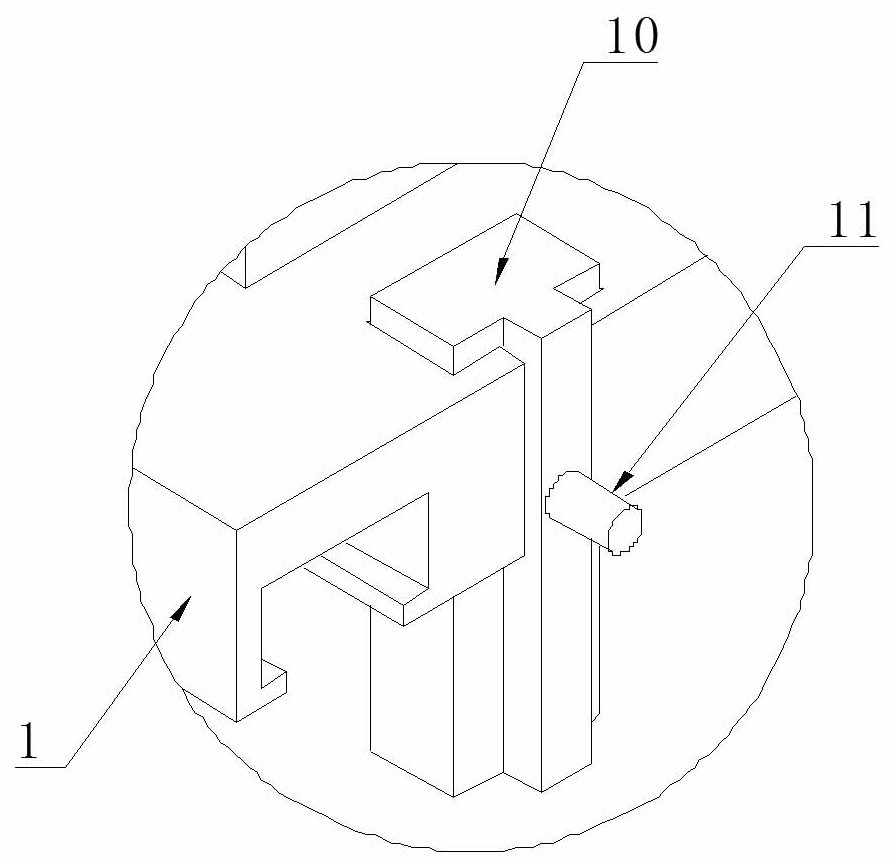

like Figure 1 to Figure 6 As shown, the embodiment of the present invention provides an environmentally friendly horizontal crushing device for recycling building material waste, comprising: a horizontally arranged base plate 1;

The pulverizer 2 is embedded and fixed on the base plate 1, the feed port of the pulverizer 2 is located above the base plate 1, and the discharge port of the pulverizer 2 is located below the base plate 1;

The pretreatment bin 3 is clamped at the feed port of the crusher 2, and a preliminary crushing mechanism 9 is arranged in the preprocessing bin 3, and the preliminary crushing mechanism 9 is used for pre-crushing the waste; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com