Biomass fuel crushing device

A biomass fuel and crushing device technology, applied in grain processing, crop processing machines, cutting equipment, etc., can solve the problem that the degree of crushing cannot meet the required requirements, waste cannot be crushed in time, and the residence time of agricultural and forestry waste is short, etc. problems, achieve convenient crushing operations, improve convenience, and achieve good crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

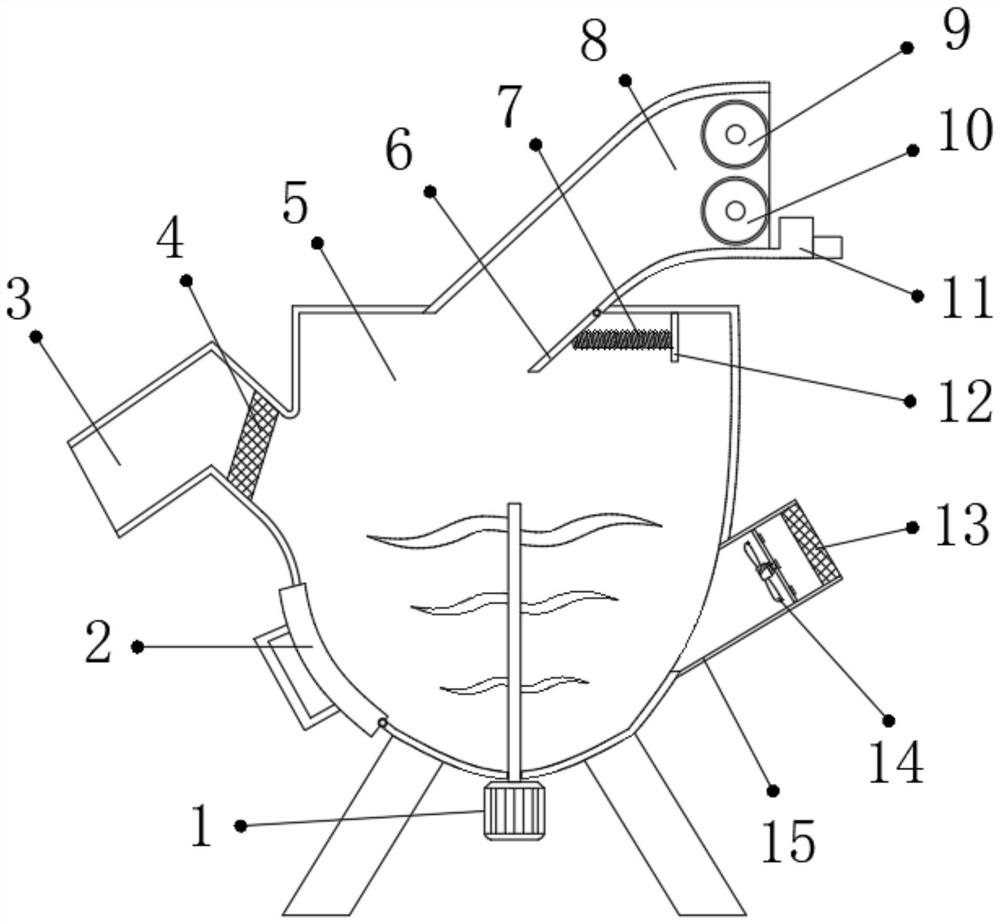

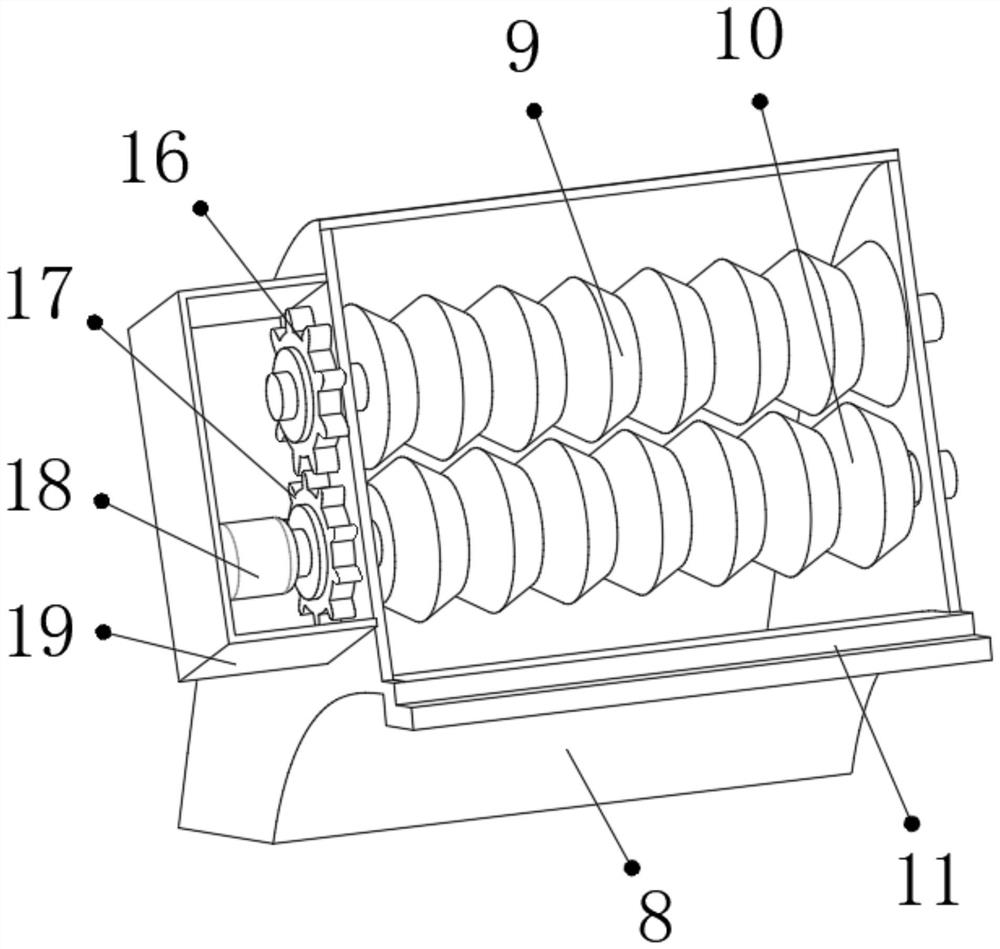

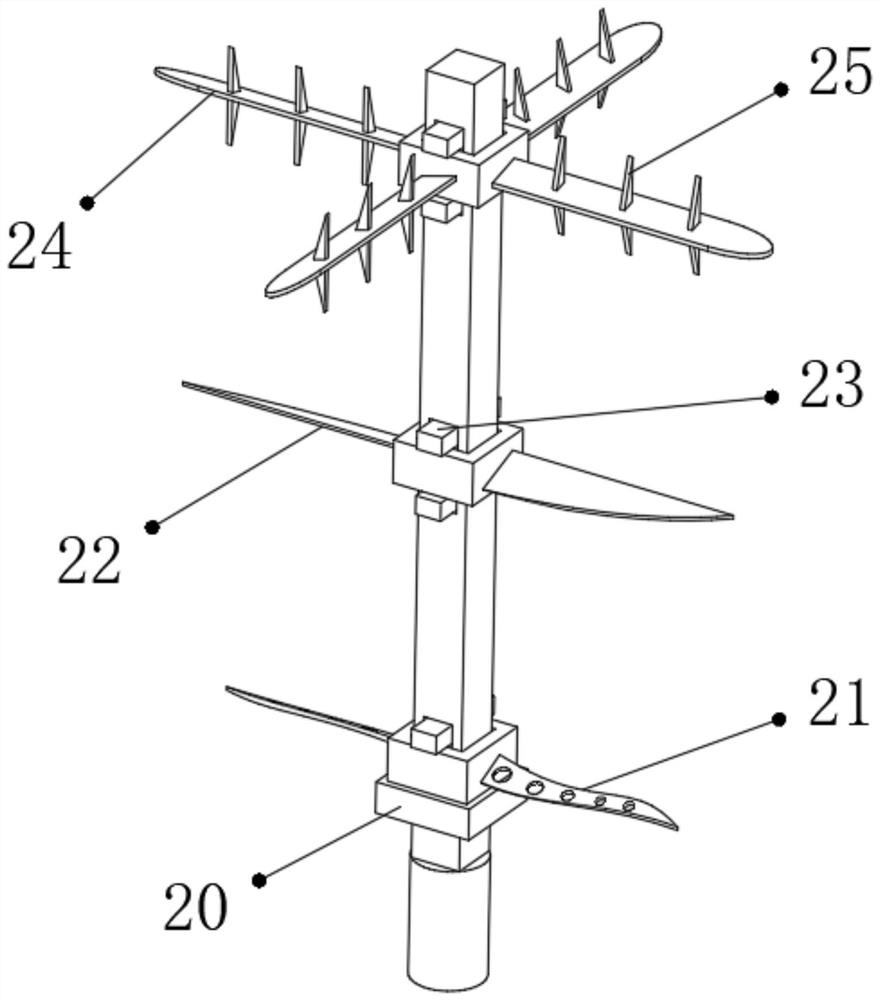

[0028] refer to Figure 1-3 , the biomass fuel crushing device, comprising a crushing box 5, the crushing box 5 is set to an acorn type, and the outer wall of one side of the crushing box 5 is welded with an air inlet pipe 15, and a certain gap is arranged between the air inlet pipe 15 and the crushing box 5 angle of inclination, the inner wall of the air inlet pipe 15 is connected with a fan support by bolts, and the outer wall of one side of the fan support is connected with a fan 14 by bolts, and the bottom outer wall of the crushing box 5 is connected with a first motor 1 by bolts, and the first motor 1. One end of the output shaft is connected with a crushing rod through bolts, and the cross-section of the crushing rod is square. The outer wall of the crushing rod is welded with a limit block 20 near the bottom. The outer wall of the crushing rod is provided with a plurality of fixing holes, and the fixing holes The inner wall is plugged with a fixed block 23, the outer w...

Embodiment 2

[0032] refer to Figure 4 , a biomass fuel crushing device. Compared with Embodiment 1, the outer wall of the discharge pipe 3 has a replacement port 26 in this embodiment, and the replacement port 26 is slidingly connected to the filter screen 4, and the filter screen 4 is connected to the replacement port 26. A gasket is provided.

[0033]Working principle: When in use, the device can be installed on one end of the conveyor and connected to the board 11. The agricultural and forestry waste enters the device under the transmission of the conveyor, and first passes through the first rolling roller 9 and the second rolling roller 10. Under the rolling of the roller teeth, the preliminary cutting is carried out, and the rolling is carried out to destroy the fibrous tissue on the surface of the agricultural and forestry waste, which is convenient for the later crushing operation. The pulverizing blade 22 is finely pulverized, and the revolving blade 21 located at the bottom assi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com